Horizontal lathes – What’s the deal?

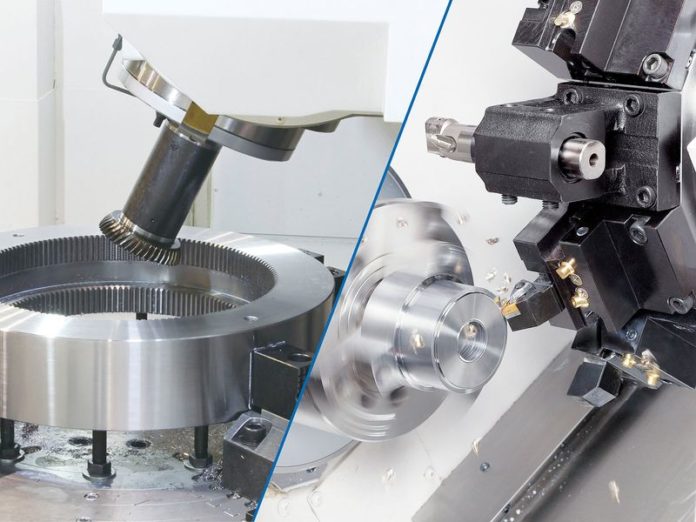

There are horizontal lathes and there are vertical lathes. While the spindle’s axis of a vertical lathe is parallel to gravity, a horizontal lathe’s spindle is parallel with the floor – so far so good. But these constructional differences have a big impact on the functionality of the machine. While horizontal lathes are probably better known and prevalent, the advantages and possibilities of vertical lathes should not be underestimated.

Let gravity be your friend!

In vertical lathes, the workpieces stand upright. As they are standing, they need far less clamping force than horizontal lathes to be held in place. More importantly, vertical lathes can be used for turning large and heavy diameter objects that are relatively short. Workpieces can include parts like large wheels or discs, large bearings, aerospace parts, heavy castings and many more.

High productivity with vertical lathes

Working with gravity side by side not only makes clamping easier but also allows for applying more cutting force. This increases the chip removal rate and reduces cycle times. Thus, vertical turning is significantly more productive than horizontal turning. Another, often underestimated, advantage of vertical lathes is that they normally need less floor space than horizontal lathes.

Turning long? Go horizontal!

While vertical lathes offer many advantages, there are things that only horizontal lathes can do. Especially when turning long workpieces, horizontal lathes display their strength. The ability to mount parts with clamps, a tailstock and maybe even a stationary or following rest allow for turning workpieces like long shafts.