Frawinhofer-IWU Perma Vib Ultrasonic Vibration System for drilling and milling tools is primarily intended for refining steel and aluminum processing

In the mechanical processing of plastics reinforced with fibers and ceramics, typical drawbacks such as tear, tearing and cutting of tools or workpiece are still present. The efficiency of machining of metal materials is limited by the weak removal of the shavings and the formation of sharp edges (sags).

Improved component quality and easy retrofitting

“The Perma Vib system, which we developed together with four industrial partners, is changing that,” says Martin Hamm, a scientist at Fraunhofer-IWU. “The system uses ultrasound to cause a vibration of the tool and thus reduces the forces that have to be applied for machining by up to 40 %. This results in smaller chip sizes, improved chip removal and component quality, while at the same time reducing tool wear by up to 50 %. In addition, existing machine tools can be retrofitted with the system easily, because it can be integrated as a module in any machining center. “Perma Vib is unrivalled in this field,” continues Hamm. “The few similar products that are on the market require the purchase of special machines and are therefore only suitable for machining smaller components.”

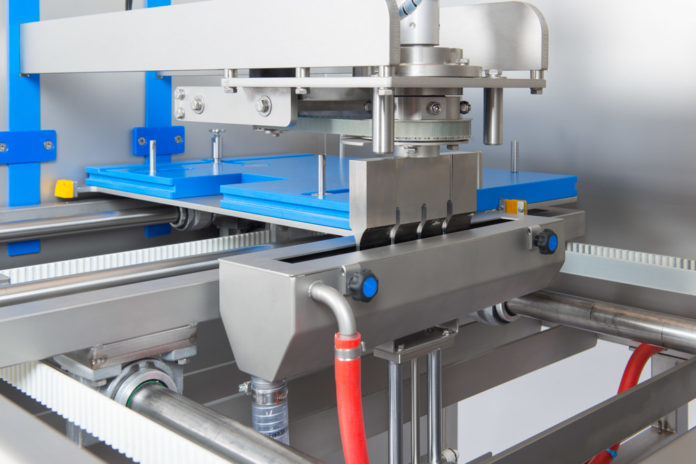

The Perma Vib is designed as a clamp-shaped tool holder, which is inserted into the spindle instead of the conventional tool holder. Inside there is a piezo-ceramic transformer that translates high-frequency AC voltage into fast movements. Thus, conventional forward movements and cuts add to longitudinal vibrations.

The Perma Vib control and power supply are independent of supplying and managing the respective processing center using an external power supply unit installed outside the work area. “That way, they do not have to change the machines, which guarantees maximum flexibility.” – explains Hamm.

Ultrasonic technology in machining systems

Interested parties can experience the use of Perma Vib at the event “Ultrasonic Technology in Machine Treatment – Systems and Effects” on November 22. Ultrasonic vibration systems were the focus of the 4th “Production Technology Conference” on the Fraunhofer-IWU test site. Participants were given the opportunity to familiarize themselves with the technical details of adaptronic components in practice during live demonstrations in a close circle of experts. The chief speeches of high-level industry representatives gave insight into the latest developments in machining.

The Perma Vib vibration system was developed in cooperation with the industrial partners Devad GmbH, EAAT GmbH, Parker Hannifin Manufacturing Germany GmbH & Co. KG and Tixbo Automotive GmbH. The project was supported by the Federal Ministry of Education and Research under the Zwanzig20 – Partnership for Innovation Program.