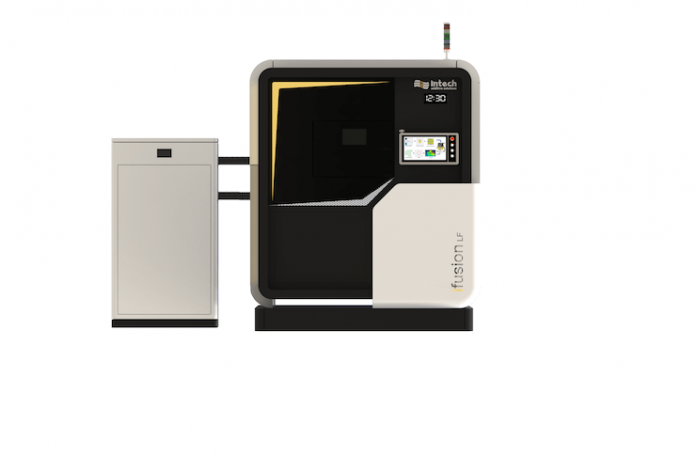

Indian 3D printing OEM Intech Additive Solutions has announced the launch of a large format metals system based on laser powder bed fusion technology.

The iFusion LF Series follows last year’s launch of the iFusion SF1, a small format system, and the iFusion LFMulti, which was equipped with a multi-laser capability. Poeir Jets, a developer of propulsion systems and micro-jet engines for unmanned aerial applications, has signed an agreement to become the first company to adopt the iFusion LF Series.

Equipped with a 450 x 450 x 450 mm build volume and available with a single 500W laser, quad 700W laser configuration and quad 1000W laser configuration, the iFusion LF is said to be designed to enable cost effective manufacturing with a high build rate and robustness.

It has been developed off the back of years of R&D by Intech Additive Solutions and will be manufactured and assembled at the company’s Bengaluru facility. Poeir Jets is set to leverage the machine to print large production parts after it successfully came through the company’s testing processes.

“The 3D printed parts from the iFusion series performed exceptionally well during the testing phases and proved to be of production quality,” commented K.S. Swami, Director of Poeir Jets. “Intech’s 3D printers helped us achieve the required scale for commercialising manufacturing and ensuring lower cost per part. We are now moving to printing parts on Intech’s LF series of machines. The LF’s larger build envelope suits our needs to print parts for our engine and Hybrid Drones. This, coupled with the lower costs compared to imported systems, local spares and support availability among other things make it an automatic choice for us.”

“The Ministry of Electronics and Information Technology has identified additive manufacturing as a critical focus area. The government plans to promote various AM sector vertical including machines, materials, software and design methodologies to leverage new and untapped business opportunities,” added Sridhar Balaram, CEO of Intech.

“This initiative will prepare the Indian manufacturing sector for industry 4.0 and evolve an integrated approach towards this emerging technology. Intech’s range of metal 3D printers is indigenously designed and manufactured for both the Indian and global markets. In this regard, ‘Made in India, Built for the World’ captures the essence of the Aatmanirbhar initiative of the Indian Government. We have an excellent team in place and are confident of enhancing and growing the Indian AM ecosystem with our range of metal 3D printers and end-to-end metal AM solutions.”