Autonomous vehicle manufacturer PIX Moving is combining metal 3D printing with mold-inspired generative design to advance automotive production.

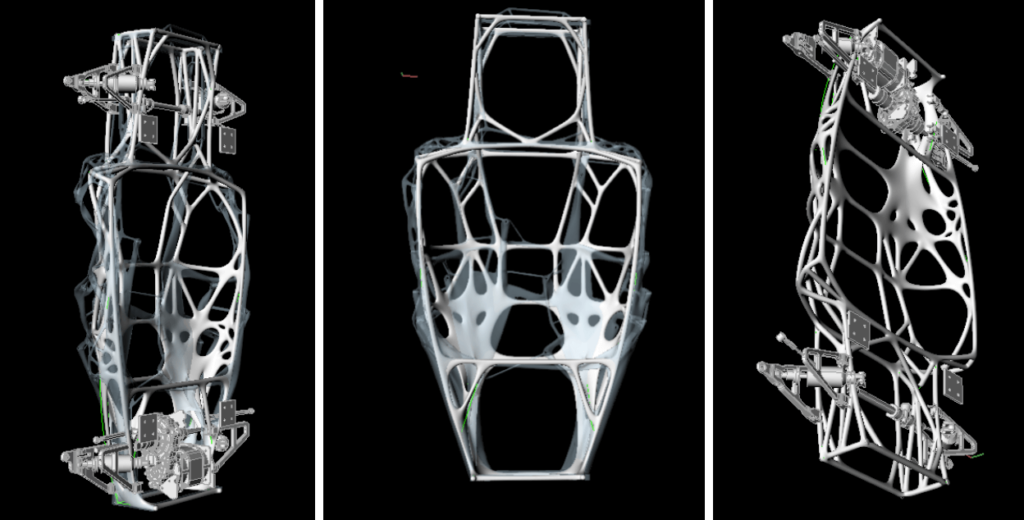

The company’s ‘C-ZONE 01’ end-to-end digital manufacturing factory makes use of wire arc additive manufacturing (WAAM), a form of large-format DED 3D printing, to produce its PIXBOT and PIXLOOP autonomous vehicle chassis models. According to PIX, the use of topology optimization and 3D printing has resulted in manufacturing cost reductions of 60% and lead time cuts of around 75%.

A PIX spokesperson stated, “We believe what we do is contributing to the paradigm shift of the car industry. With the new tools and vision, we can rebuild the manufacturing and mobility of cars.”

The slime mold algorithm

PIX’s first run-in with WAAM 3D printing occured in 2019, when the company prototyped its first autonomous vehicle chassis. With the main challenge being the incorporation of WAAM constraints into a generative design workflow, the company attempted to perform structural optimization using readily available tools such as Autodesk Generative Design, PTC Frustum and Altair Inspire. While these programs worked quite well for conventional manufacturing techniques and even PBF 3D printing, WAAM proved to require a much stricter set of parameters.

To overcome this, PIX engineers took it upon themselves to design their own generative design algorithm, which they called the ‘slime mold algorithm’. Drawing inspiration from the pathfinding abilities of a slime mold in a petri dish, the algorithm enabled the company to automatically model its chassis prototype with the constraints of WAAM 3D printing in mind.

Using generative design to 3D print chassis structures

Each design iteration created by the tool undergoes static finite element analysis (FEA), where the performance of the structure is assessed with simulated stress and deformation. A human designer is then used to perform ‘touch ups’, further optimizing the base model in accordance with WAAM’s strict constraints. It is ultimately up to the designer to strike a balance between structural integrity and weight, as material reductions tend to increase the risk of deformation in a part.

This generative design-focused 3D printing workflow comprises the bulk of PIX’s production process, even to this day. The company now aims to 3D print, in high-volume, the next generation of autonomous vehicle chassis structures with significant part consolidations, major weight savings, and minimal lead times via WAAM.

PIX’s computational design team wrote, “This is necessary to revolutionize car manufacturing, which has not seen much change since Ford first introduced the assembly line about a hundred years ago.”