In Spain, the first 3D printed respirator has just been developed and approved by medical experts.

In order to support hospitals and intensive care units in the face of the current health crisis, the consortium comprising Consorci de la Zona Franca (CZFB), HP, Leitat, SEAT, Consorci Sanitari de Terrassa (CST) and the Parc Taulí Hospital in Sabadell, designed a 3D printable respirator. The device is an emergency device that can help patients breathe for a short period of time. The alliance aims to industrialize its production in order to be able to produce hundreds of these units per day.

As you well know, the 3D printing community has mobilized to face the shortages of medical equipment over the world. Initiatives to develop 3D printed masks, goggles or shields are already taking place. However, many of these initiatives have unfortunately not been medically validated.

For example, many who own 3D printers have embarked on the production of 3D printed masks, but their efficiency, durability and most importantly safety has yet to be confirmed. The medical profession has to validate any equipment it uses, whether or not there is a shortage. In this case, it appears that the Spanish initiative has succeeded in producing a medically approved device that could be produced on a large scale.

Designing the 3D printed respirator

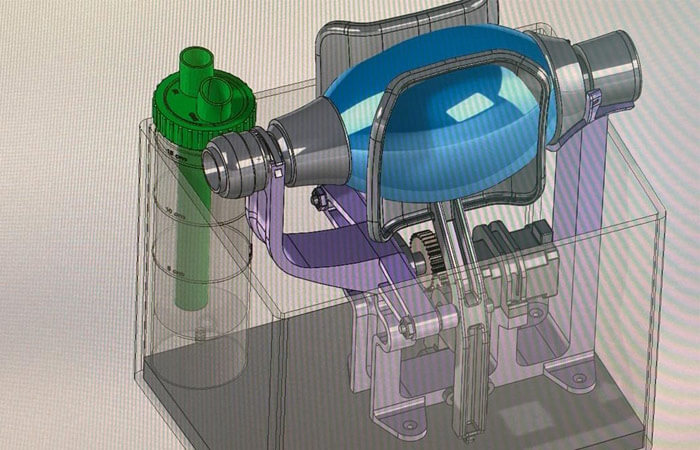

It’s the Leitat Technology Centre that developed the 3D model behind this emergency breathing device. Called Leitat 1, it is a field device that has been simplified, reducing the number of components needed for an easier assembly. The device was designed by Mr. Magí Galindo, an engineer at the Spanish centre, and then medically validated by Dr. Lluís Blanch, Director of Innovation at the Parc Taulí Hospital in Sabadell, an expert in mechanical ventilation.

Source: 3dnatives

The first prototype was produced using 3D printing technology using the machines of the various project partners, meeting all the requirements and functionalities expected of such a device. Leitat says that between 50 and 100 units could be created every day starting next week. In fact, production has already started, and the different partners are already working on a second model, the Leitat 2, which should be more in line with the regulations of the Spanish Agency for Medicines and Medical Devices.

Manel Balcells, Health Commissioner at the Leitat Technology Centre concludes: “This is an emergency respirator, for an emergency situation, designed with 3D technologies and incorporating other parts found on the market. Assembly is very fast, so we can produce about 100 of them per day, and I hope many more in the days to come.”