Presenting multi-axis operations in an immersive environment helps trainees and experienced machine operators to learn, understand, and practice advanced machining techniques.

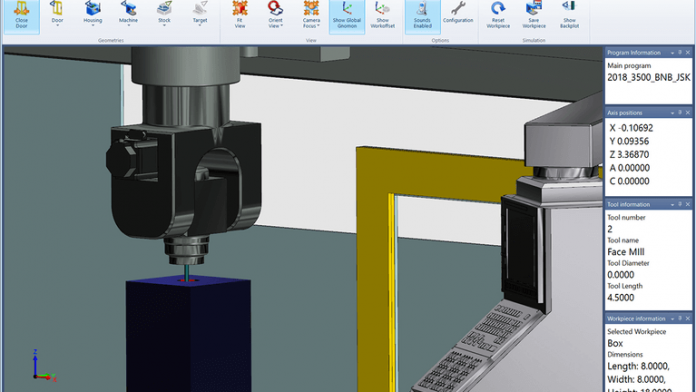

Automation and CNC developer FANUC AMERICA has expanded its training platform to include five-axis simulation. FANUC’s Machining Simulation for Workforce Development offers training for controls operation and part programming in a virtual environment, and the Complex Milling Extension option combines FANUC’s CNC Guide with simulation software, so that now these operate as one of the three main, five-axis mill kinematics.

The new capabilities also includes training on a three-axis mill and a two-axis lathe, for maximum configuration flexibility.

Through digital-twin capability, the five-axis machining simulation allows users to learn how to set-up and operate three common, advanced five-axis milling machines: mixed type, tool type and table type.

Five-axis simulation is presented in an immersive environment so machine operators may learn, understand, and practice advanced machining techniques. Because five-axis machining demands more complex machine setups, the simulation software effectively teaches users how to take advantage of the options and features available in a multi-axis setting.

Additionally, the five-axis machining simulation software allows machine operators to experiment with and “prove out” the machine setup and/or part program before modifying the actual machine.

Interest in five-axis machining continues to expand, as more manufacturing operations seek to produce complex parts — notably parts required by customers in high-tech industrial segments, such as aerospace and medical devices. As this type of need increases for machine shops, their need for operators with five-axis skill will grow, too. Finding qualified workers to fill those positions will be a challenge for many employers, especially in a labor market shaped by a “manufacturing skills gap“.

Training new workers, or current workers, will help to bridge that gap, and FANUC is working with industrial and educational partners to address the need for training in five-axis programming and operating skill.