European launch of the Field system, a new IIoT platform has been carried out by Fanuc at the recently concluded EMO Hannover exhibition in Germany.

The Fanuc Intelligent Edge Link and Drive system has the capability to link together production machines from different manufacturers and generations in a single factory.

Fanuc is well recognised by the manufacturing industry as it offers a wide range of quality automation solutions such as robotics and CNC wireless systems to its customers. The company regularly exhibits its most recent innovations at industrial trade shows and at the recently held EMO Hannover exhibition the company did just that.

Fanuc Intelligent Edge Link and Drive system

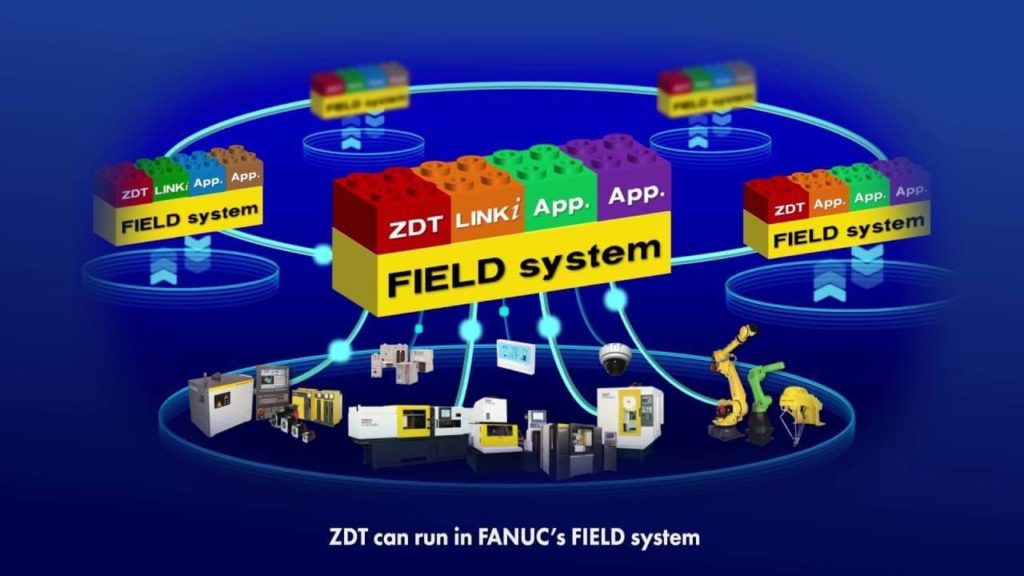

Fanuc carried out the European launch of its new IIoT platform – Field system at the grand metalworking technology show. The full form of ‘Field’ is Fanuc Intelligent Edge Link and Drive and one of the main features of this system is that it is an open system. This means that it has the capability to link together production machines from different manufacturers and generations in a single factory, thus enabling comprehensive data analysis to be conducted along the entire process chain and propelling users ever closer to the coveted smart factory.

Collecting and analyzing machine data directly on site

This is not all. In addition to this, the IIoT platform has another significant feature which makes the Field system unique when compared to its other competitors. The new system collects and analyzes machine data directly on site (edge heavy), without first transferring it to the cloud. In other words, the platform is equipped to process data in the factory without any delay which helps to speed up the production process, and thus improving its efficiency.

Exclusive cloud solution

Fanuc claims that the Field system is the sole IIoT platform which offers users with an option to either store the data in the factory or upload it to an external cloud. The system runs locally and hence, on detecting a problem in the ongoing production process one is able to take actions quickly without the need to connect to a cloud.

However, if users are not satisfied with this process, they can also make use of the Field system’s cloud solution that has been especially designed for storing data for future evaluation or perform data analysis across multiple production sites. For the convenience of its customers, the company has also made available Field system apps on the Fanuc app store via the cloud.

With so many benefits and unique features, Fanuc attracted multiple eyeballs at one of the leading shows for metalworking technology, EMO Hannover 2019. We are certain that the company must have also received a few potential inquires for their new and innovative platform.