The 21st century has brought on a revolution in several industries globally. Similarly, in the manufacturing industry, CNC production has completely revolutionized the industry due to its outstanding capabilities. When compared with conventional processes, the modern CNC processes have enabled the manufacturers to produce more complex geometries in less time and with greater repeatability. Another aspect that increases the worth of CNC machines is the fact that the cost of mass producing any prototype has been considerably decreased. Today, CNC machines are being used for both prototyping and producing industrial and domestic products all around the world.

What are CNC machines and how they operate?

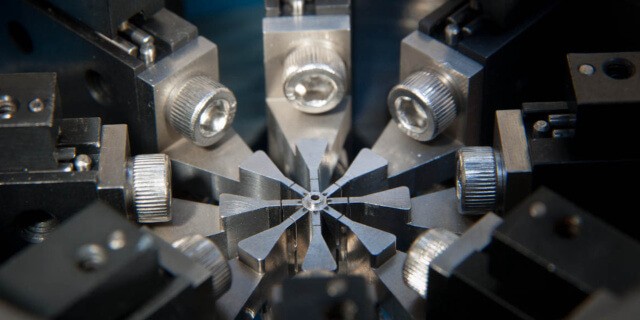

CNC, meaning Computer Numeric Control, is a set of different machines that use a computer to direct the interaction between the machining tool and the work-pieces. Machining is the mechanical process of transforming a large bulk of material such as a block into a finished product through the material removing process. The Machines are controlled by a computer that interacts with the machine through a series of codes called G-Codes and M-Codes. These codes are generated by commercially available software called Computer Aided Manufacturing software. The CAM software possesses the ability to transform the 3D computer model into an understandable language for the machine. The CNC Machines available in the market today are divided by their capability of catering to a different number of axis. For example, the 5 – axis CNC Machine is quite popular in the prototyping industry because of its capability of producing extremely complex geometrical shapes. Similarly, the machines are also classified by the different functions that they can perform such as; CNC Lathe, CNC Milling Machine, CNC Water Jet Cutter, CNC Laser, etc. For any manufacturer, the ideal machine for CNC production is subjective to the operation he wants to perform and the resources available.

Today, CNC machines have become an important part of several industries globally. Following are the list of some industries where CNC production is being used quite regularly.

- Aerospace

- Agriculture

- Automotive

- Construction

- Dental

- Electronics

- Firearms

- Hospitality

- Manufacturing, all types

- Metalwork

- Military

- Production

- Publishing

- Transportation

Advantages of CNC production

It is common knowledge that CNC machines have revolutionized the manufacturing industry, but what exactly makes CNC, a better alternative than the conventional machining methods available in the market today? Some of the most common advantages of CNC Machines are listed below:

1. Unmatched Precision

With CNC Production Capability, the precision of all products will be off the charts. CNC machines have perfected the art of precision and have their accuracy within a thousandth of an inch.

2. Round the Clock Production

As opposed to human workers, CNC machines can work for 24 hours without taking any break and maintain consistent quality. The factory’s ability to meeting tough demands in a shorter timespan increases tenfold due to CNC machines.

3. Mass Production and Scalability

CNC Machines are an ideal choice for mass producing the same part. They can run 24/7 and once the data has been transferred to the machines, there is no need for further instructions. Similarly, with CNC machines, taking CNC machined aluminum as an example, scalability has become extremely easier. You can increase the size of your model by any factor you want without doing any tedious calculations. All the required adjustments will be carried out by the machine automatically.

4. Increased Capability

With the introduction of multi-axis CNC machines, the production of complex and unattainable geometries has become easier. Before CNC, a complicated part would have to be processed multiple times as traditional machining methods were prone to many errors. In addition to that, a lot of material used to get wasted before CNC machines, but now all of this has changed. CNC machines allow greater freedom to the manufacturers at a lower cost.

5. Repeatability

As discussed previously, CNC machines can handle extremely low tolerances perfectly, and once data has been updated in the machine, no further input is required. This allows the CNC produced parts to be perfectly identical, which is almost impossible to achieve using traditional methods.

6. Better Safety

Ensuring Health and Safety is the moral and legal responsibility of an employer. Traditional Machines were prone to many accidents and mishaps, but with CNC machines, the probability of accidents is significantly reduced. All CNC machines have several safeguards that allow them to ensure a safe working environment.

7. Versatile Production

With the use of CNC Machines, you are not limited to a specific kind of products. The possibilities are endless in CNC Production because of the innovative and state of the art features being offered by the CNC machines.

How Can WayKen Help You?

WayKen Rapid Manufacturing is the leading expert in this field and we possess all the latest technology to cater to your needs. Whether you need CNC Production services for prototyping of a new product or to increase your production output through mass production, WayKen has all the resources you need. Some of the services being offered by our company are;

- Prototype Machining Services

- CNC Aluminum Machining Services

- Clear Optical Prototyping Services

- Manufacturing of Low Volume Products

- Production of Working Prototypes

- Automotive Industrial Prototyping Services

CNC Production for Your Business

If you are an owner of a manufacturing company, looking at the possibilities being offered by CNC machines is not optional anymore. The world is changing at an extremely rapid pace and day by day, new innovations are being introduced in the industry. With CNC machines, you can stay ahead of your competition and take your business to the next level.