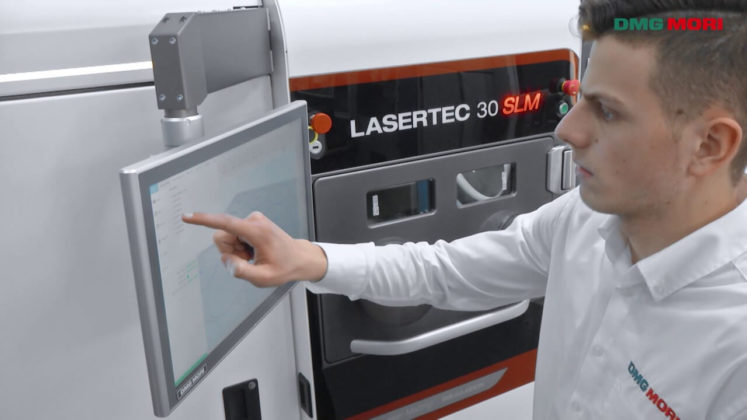

DMG MORI Lasertec 30 SLM 2nd Generation Offers Open Parameters.

We’ve talked in exclusive video interview with Mr. Ralph Rösing, managing director with DMG Mori.

The second generation of DMG MORI‘s selective laser melting platform enables users to adjust print settings and select any material.

The Lasertec 30 SLM 2nd Generation from DMG MORI supports powder-bed additive manufacturing via selective laser melting. The second generation of this platform offers a 11.8″ × 11.8″ × 11.8″ volume and features the Stealth design for user comfort. The platform supports the manufacture of workpieces fully via AM, as well as printing on top of previously milled base plates and bases without the need for support structures.

The company’s CELOS CAM programming and machine control enables programming parts externally and transferring them to the machine regardless of complexity. The control is said to ensure optimal processes in the pre- and postprocessing of additively manufactured parts. The open system of the Lasertec 30 SLM 2nd generation enables adjustment of all machine settings and process parameters, including material.

The RePlug powder module system enables fast material exchange. According to the company, this module enables change-over of materials in less than 2 hrs. Additionally, the closed material circuit ensures safety and enables process autonomy.

Additive Manufacturing by selective laser melting (SLM) in powder bed:

- Highly complex components with function integration

- Internal close-contoured cooling channels

- Weight optimisation due to lattice and honeycomb structures as well as topology-optimised components

- Simultaneous build-up of different designs

- Functional prototypes made of series materials