The machining of ISO N materials such as wrought aluminium alloys and cast aluminium alloys or copper presents a challenge for tools.

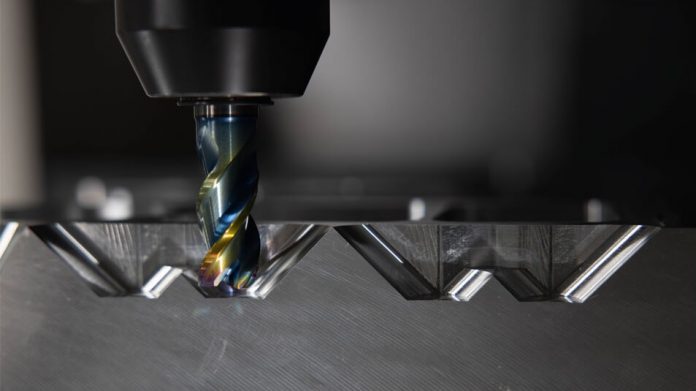

Walter is launching a product line developed especially for this with the MC267 Advance solid carbide milling cutters. The universal milling cutters with centre cut and diameter of 1 to 20 mm are suitable for a wide range of applications, including sectors involving micro machining operations, such as the electronics industry.

With two or three flutes, they can be used on machines with a different performance spectrum, for roughing as well as semi-finishing and finishing. The combination of geometry (45° helix angle) and low-vibration micro geometry enables a high level of stability and process reliability.

Philipp Binder, Product Manager for Milling Round Tools at Walter, states: “With the MC267 Advance ISO N milling cutters, we are offering a new tool that is capable of full slotting and ramping in a coated and uncoated version. Thanks to the excellent performance level and an attractive price, the tool offers advantages both for general mechanical engineering and residual material machining, for example of tight radii on structural components in the aerospace industry.

Also in applications where maximum performance is not the top priority. Alongside the MC267 Advance itself, our customers also benefit from our extensive aluminium range, which our many years of expertise have gone into. For retailers, the focus is likely to be on the large potential customer base and the universality of the milling cutters.” The tools are delivered within a maximum of three weeks via Walter Xpress.