Big Kaiser’s FLM and ELM insert chipbreakers are designed to improve surface finish in long-chipping materials.

Long chips that are difficult to evacuate can lead to poor surface finishes, reduced insert life and machine crashes.

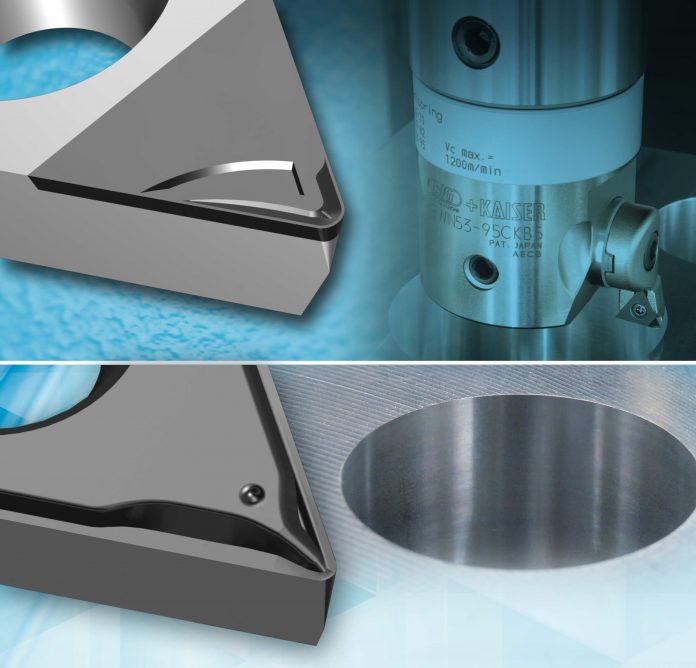

The FLM 3D chipbreaker design, used on PCD-tipped inserts, is well-suited to finishing aluminum components, where traditional flat-top inserts may produce a large continuous nest of chips that is difficult to remove from the bore and/or tool. Three different radius options are available: 0.008″, 0.016″ and 0.031″ for the TCGT2 insert.

The ELM chipbreaker, used on cermet inserts, is well-suited to finishing mild or construction steels. Available in a 0.008″ radius and combined with a light depth of cut, this chipbreaker provides a high-shear angle to shorten the cutting chips, improving evacuation and resulting in better surface finishes.