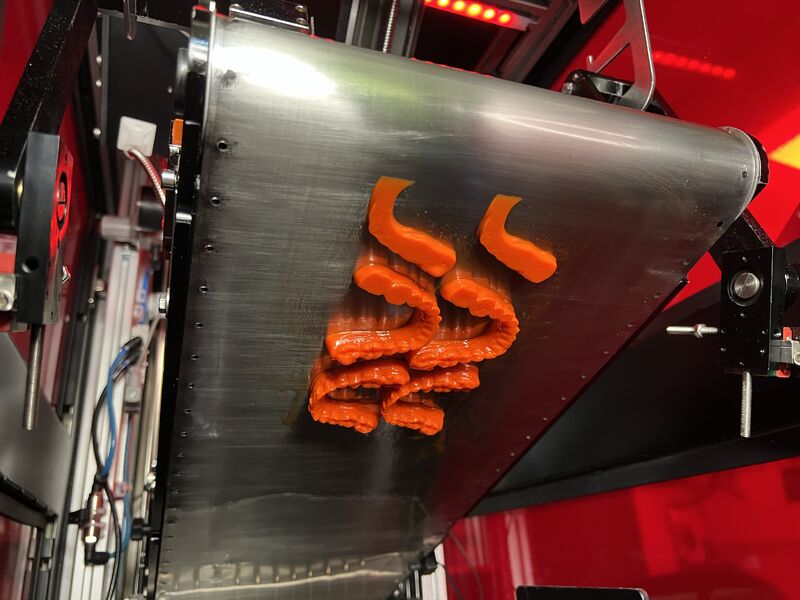

Israeli start-up Sprybuild has unveiled its new Stereolithography (SLA) 3D printer featuring a patented continuous build process on a conveyor belt and rigid optical interface.

Enhanced resin flow for high-speed printing

Incorporating a distinctive conveyor belt system, Sprybuild’s SLA 3D printer effectively stabilizes the print surface. Through the utilization of a patented magnetic mechanism, this system achieves surface stability while enabling the automatic release of printed parts, thereby reducing printer downtime. Addressing prevalent challenges in resin-based 3D printing, Sprybuild’s solution mitigates issues such as resin hindrance from oxygen or light and the occurrence of ‘dead zones’ for uncured resin. By effectively resolving these issues, the printer guarantees a consistent resin flow into the printing area, a critical factor in achieving high-speed printing.

During recent tests, the 3D printer achieved successful printing of dental models at a speed of 55 mm/min, boasting a layer resolution of 100 microns. The company reports its potential to attain speeds of up to 150 mm/min. According to the company, this performance is notably faster, approximately 2.5 mm/min, compared to the average commercial resin 3D printer. The solid optical interface, akin to but distinct from Carbon‘s Continuous Liquid Interface Production (CLIP) technology, plays a pivotal role in enhancing this speed. It facilitates efficient resin flow and targeted curing, contributing to the printer’s accelerated performance.

The company asserts that the design of the SLA 3D printer renders it suitable for a multitude of applications, including but not limited to dental models, shoe soles, orthopedic insoles, eyeglass frames, fashion accessories, hearing aids, prosthetic components, printed molds, and combustible models for precision casting.

With its automation features and compatibility with commonly used UV resins, the printer presents opportunities for cost savings in production. Additionally, automated slicing, nesting, and post-processing units streamline the printing process, efficiently managing complexity and enhancing overall productivity.

Scaling up production with SLA 3D printing systems

The ability of SLA 3D printing to produce high-resolution parts with complex details has made it ideal for use across various industries, including healthcare, automotive, aerospace, and consumer goods. Over the years, many companies have added SLA 3D printers to their expanding portfolios.

For example, in 2022, 3D Systems introduced the SLA 750 and SLA 750 Dual, Accura AMX Durable Natural resin, PostCure 1050 post-processing system, and Oqton Manufacturing OS software.

These products target large-format, high-volume production across various sectors such as automotive, consumer goods, aerospace, and healthcare. With the SLA 750 Dual offering double the print speed through a dual-laser system, these printers boasted size and resolution improvements among others. Equipped with self-calibrating dual-rail recoaters and Hyper-Scan vector technology, the SLA 3D printing systems offer improved process reliability and part quality.

On another note, 3D printer manufacturer Formlabs released the Form 3L, an upgraded SLA-based desktop system tailored for footwear, industrial, and medical applications. The printer features an expanded build volume and future compatibility with bio-resin.

Utilizing low-force stereolithography (LFS) technology, it offers faster production times and greater part accuracy. With a build volume of 33 x 20 x 30cm, it enabled the printing of larger-scale parts or multiple small components in a single run. As reported by the company, the enlarged print bed benefited partners like New Balance in producing larger end-use insoles.