A retrofittable, accelerometer-based system cuts tool-head vibration to maximize MRR and make PM possible.

An accelerometer-based active vibration-control system for CNC machine tools is designed to improve machining productivity by maximizing material removal rate (MRR), with the result that tool-head vibration is “virtually eliminated”, according to the developer. The system, developed by NUM, also provides real-time feedback for predictive maintenance.

It is available as a retrofittable option for any machine tool that uses NUM’s MDLUX digital servo drives, which are part of its Flexium+ CNC platform.

The cost-effective, active vibration-control system provides exceptional dynamic damping capabilities, too.

Source: American machinist

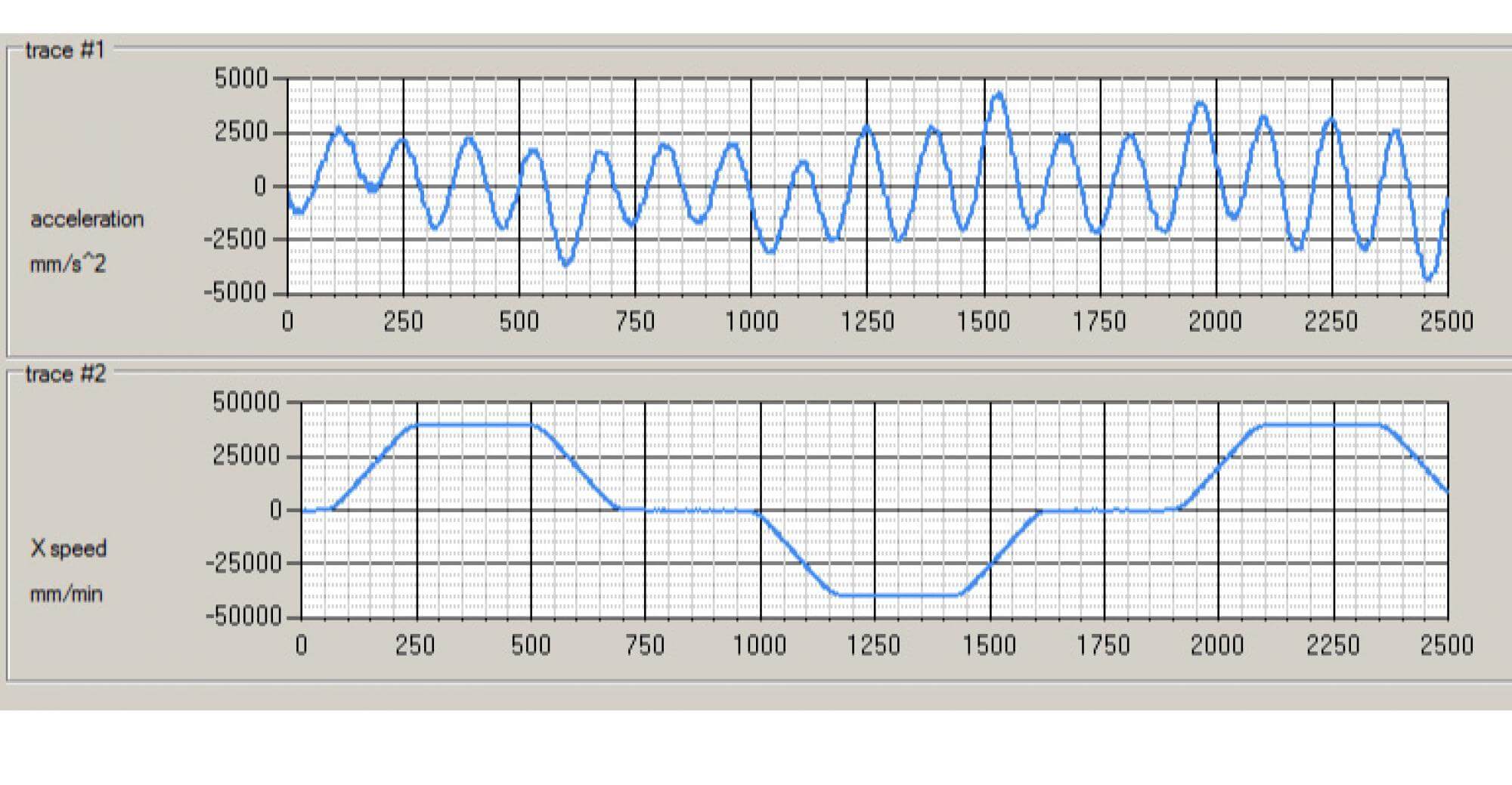

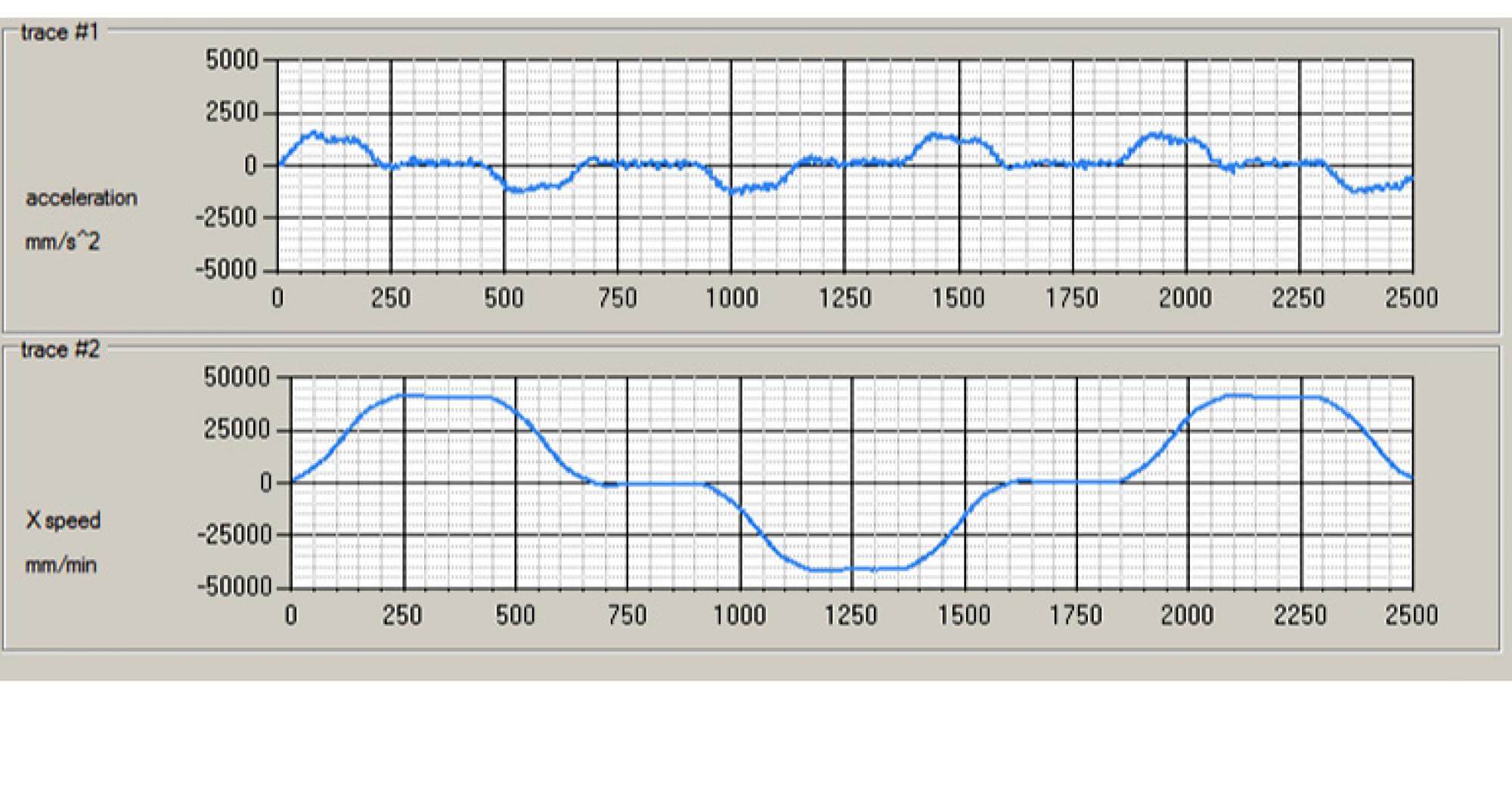

Most accelerometers are capable of low-frequency sampling rates and require additional signal conditioning electronics before they can be connected – usually via Fieldbus – to the CNC or PLC system. Typically, acceleration data can be retrieved once every 20 milliseconds, which is inadequate for vibration damping purposes on machine tools. The accelerometer in NUM’s system is sampled every 100 microseconds, which means that it can be used for closed-loop control at bandwidths approaching several hundreds of Hertz.

The small flange-mounting accelerometer transducer can be attached easily to the machine’s tool head and has a sensitivity of 0.02 g (1.96 m/sec/sec.), with a measurement range of ±2 g (±19.6 m/sec/sec.) The transducer connects directly to the digital servo drive, obviating the need for any additional signal conditioning circuitry.

The active vibration-control system uses the drive embedded macros (DEM-X) option available on NUM’s MDLUX digital servo drives. This option enables real-time macros to be embedded within the drive to manipulate its regulation algorithms.

Thus, the output signal from the accelerometer transducer can be used to influence the behavior of the speed servo control loop. All MDLUX servo-drive modules use advanced DSP control techniques to maximize the CNC kernel-to-drive servo bus speed, and feature high-loop bandwidths and special acceleration algorithms for uncompromised speed and positioning accuracy.

Source: American machinist

One of the most interesting applications of the NUM active vibration-control system concerns Tool Centre Point (TCP) vibration due to the various vibration modes of a machine tool’s mechanical structure. Until now, even if the machine is equipped with a high-resolution encoder (integrated in the servo motor) it has been impossible to damp the TCP vibration, simply because it is not measured.

Although complex system modeling and state-space control could possibly provide some effective results, the complexity is very high and the compensation robustness is quite weak. For example, in the case of a small parameter change, such as inertia, the effect of the compensation would be lost entirely.

However, using NUM’s new active vibration-control system it’s possible to measure and dynamically alter the TCP acceleration in each of the main X, Y and Z axis directions, and so to damp the vibration very accurately. Using this approach, tool-head vibration can be effectively eliminated, reducing tool wear significantly and maximizing the MRR of the machining process.

All acceleration data is processed within the drive in the digital domain, meaning that it can be cyclically transmitted to the Flexium+ NCK and stored in the NCK buffer. Then, the data can be uploaded to the Windows operating system for further evaluation, or for use with NUM’s process monitoring software.

It is especially useful for preventive maintenance applications, where it can provide early indication of potential machine problems before they become expensive repair tasks. Typically these include detecting spindle vibration caused by bearing problems, detecting the onset of performance deterioration such as increased friction or backlash, and detecting excessive tool wear or breakage.