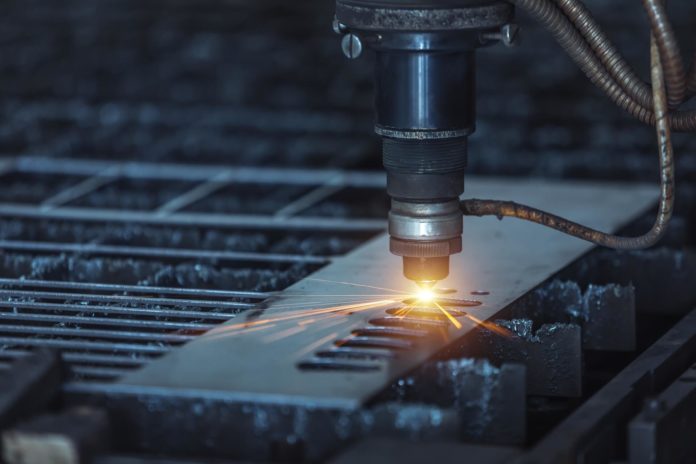

DK introduces a new fixturing system for working with laser technology.

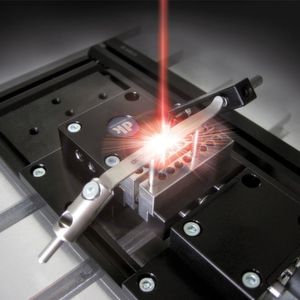

They are said to be easy to implement and offer the required degree of precision.

DK Fixiersysteme GmbH & Co. KG is a manufacturers of modular fixturing systems for positioning and clamping parts sized 0.1 to 1000 mm. The diversity of the standard elements, the compatibility of the five main programs and the quick-change system justifies this position.

Based on the fixturing systems for optical and tactile measuring technology that has been tried and tested over many years, DK now brings innovative solutions for laser technology, especially laser engraving technology onto the market.

The company says the requirements of laser practice are almost identical with those of part positioning for measuring technology:

- Positioning in the optimal position for the lasing process

- Secure hold with minimum force

- Precise, repeatable fixation of the part to be lasered.

Modular elements for the simple construction of constantly new fixtures:

- Exactly reproducible reconstruction of disassembled fixtures for identical fixation positioning

- Pallet system for setting up away from the laser device

- Solutions for electronically controllable rotary movements of the workpiece

The resulting advantages for the industry are clear:

- Quick and easy implementation of new workholding fixtures

- Precise fine adjustment of the position through infinitely adjustable add-on elements

- Quick changes between the different workholding fixtures

- No expensive storage of inflexible single-use fixtures

- Increased OEE through higher utilization of the laser due to setups outside the machine

- Controlled rotary motion for lasing cylindrical elements with compatible data communication.

All in all, the modular fixturing systems from DK save time, costs and resources.

To support planners and users, DK has made 3D models of the fixturing systems available on their homepage. This does not only support the new planning of fixtures, but also eases their documentation enormously.