During Moulding Expo, HRS flow presented a new series of hot runner nozzles called SA to process small technical components in tools with a very compact cut-out.

Moreover, the company showcased the extensions of its cylinder portfolios which are particularly compact and require little installation space, including types that have been developed for exact needle adjustment, according to the company.

With the new particularly small-sized hot runner nozzles of the SA series, HRS flow has expanded its range by adding a size, which is ranked below the smallest P series to date. The new screwed-in nozzles are suitable for the injection moulding of techno-polymers with a shot weight of about 1 g and less and for wall thicknesses below 1 mm. Their selectable gate versions, open nozzle and valve gate are available with bushing through the cavity or gate on the cavity. The shape and material of the tip, the channel section and the contact surface of the end ring with the cavity are designed to have the optimal thermal conditions which enable a high flexibility in processing engineering polymers, the company says.

Their typical applications range from the automotive industry to technical components, houseware and logistics & environmental applications including productions with frequent color changes as well as the processing of glass fiber reinforced plastics or the moulding of parts with particularly high-quality surfaces for subsequent painting or coating processes. The use of stack moulds is also possible.

The compact design of the new SA series enables a compact cut-out in the tool. At the same time, the relatively large melt channel diameter allows the processing of highly reinforced or highly viscous plastics at high flow rates. The nozzle screwed on the manifold guarantees the seal at high injection pressure without requiring accuracy in the machining of the mould.

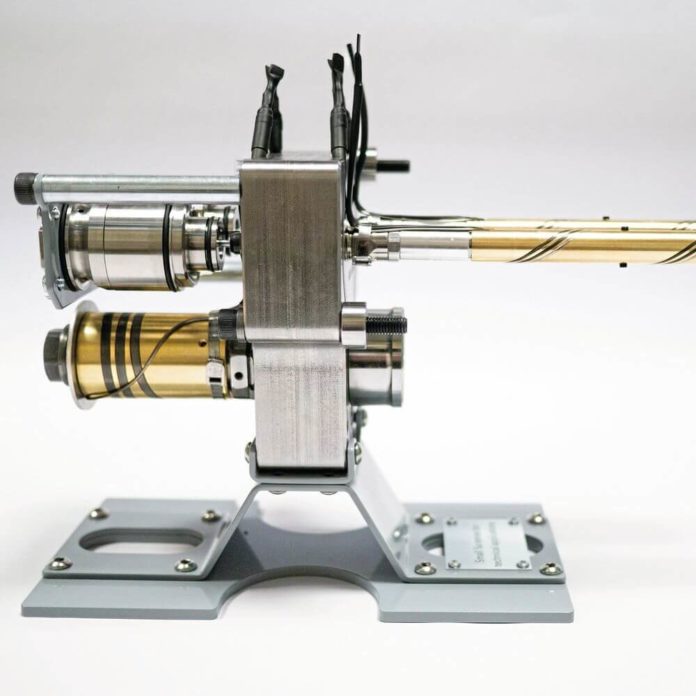

HRS compact hydraulic cylinders

HRS flow’s extended cylinder portfolio now includes compact hydraulic cylinders, which require small cut-outs in the tool and provide an increased thermal insulation thanks to components material and optimised contact surface. This minimises the heat transfer to the manifold and reduces energy consumption. Here, in addition to the basic version, a version with needle damping is also available. Further variants offer a microswitch version for the double needle end position detection as well as the possibility of compensating the position of the needle by ± 1 mm without mechanical reworking thanks to the adjustable version.

HRS cool

Finally, HRS cool is HRS flow’s solution for hot runner injection moulding in which the water cooling of the associated actuators can be completely eliminated for the most common automotive applications. Support columns with optimised contact surfaces minimise the heat transfer from the hot tool plate to the cylinder, while a height-adjustable cover plate made of a highly thermally conductive material ensures the maximum heat dissipation from the cylinder to the cold clamping plate. By removing all elements required for active cooling, such as ducts, pipes and connections, HRS cool eliminates issues associated with clogged cooling circuits.