Ultra-precision machining is revolutionising the way parts and surfaces are machined. Moduleworks says its ultra-precision kernel does just that.

Originally developed for machining optical parts such as spherical and aspherical lenses used in telescopes, ultra-precision machining is revolutionising the way parts and surfaces are machined. Ever more milling and turning centres now offer the physical and thermal stability to cope with accelerated spindle speeds, enabling ultra-precision machining to be used not only for diamond turning but also a wide range of new applications on standard micro-milling machines. With the hardware in place, CAM software is now the game-changer, especially in the nanotechnology manufacturing industry, offering OEMs and end-users the dedicated functionalities and high-performance they need to differentiate themselves from the competition.

High-performance software is important. Generating toolpaths capable of machining parts to an accuracy of just a few µm and a roughness in the range of nm requires sophisticated, high-performance algorithms. According to Moduleworks, its high-performance 64-bit ultra-precision kernel is specially designed to accelerate the calculation of ultra-precision toolpaths and speed up the programming and production of complex free-form parts and surfaces.

Based on its industry-proven Moduleworks 5-axis technology, the ultra-precision kernel uses multi-threading for fast toolpath generation with radial, spiral and parallel patterns for slow and fast tool kinematics. It also brings a full-set of dedicated functionalities to be cost-effective, fully-flexible and allow for high-quality machining to ultra-precision applications, like:

- Support for point clouds, Nurbs surfaces and parametric geometries.

- Freely configurable machine model supports all machine tool types for grinding and diamond turning.

- Grinding patterns for roughing, drilling, chamfering, slotting and contouring.

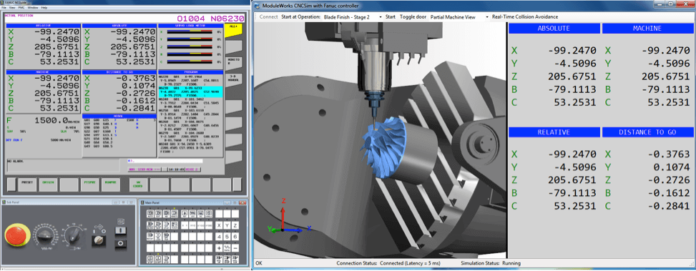

- Full 3D collision detection.

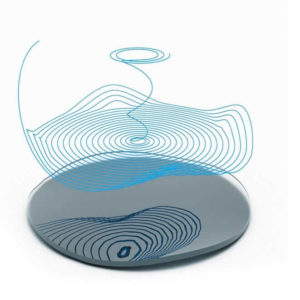

The latest release, Version 2019.04 extends the functionality by enabling users to generate toolpaths from a set of imported guide curves.

The guide curves are projected onto the machining surface where the resulting trajectory is followed by the cutting tool. This provides greater flexibility and control over the generated toolpath and enables the production of 3D images (e.g., specular holographs) as well as non-rotational surfaces, the company says.

The toolpaths can also be morphed between the set of imported curves. By manually defining the maximum stepover and cut tolerance, users have full control over the surface quality and accuracy of the machined products.

Moduleworks also offers 3D machine and material removal simulation with the high-resolution requirements of ultra-precision machining to provide the full range of high-performance SDKs that enable CAM vendors to deliver the latest, innovative technology to end-users in the shortest possible time.