The Chiron Group, Tuttlingen, Germany, a specialist in the field of CNC-controlled vertical milling and turning machining centres, has developed its first Additive Manufacturing machine, the AM Cube, for the production of large and complex components.

According to the group, the AM Cube is based on a conventional cartesian coordinate system, like a CNC machining centre, and operation and programming of the AM Cube is intuitive. The system is programmed using either a standardised DIN ISO code or, for complex components, using a CAD/CAM software tool. All aspects of the system can be controlled using tried-and-tested Siemens components, from hardware to the HMI through to programming of the AM Cube.

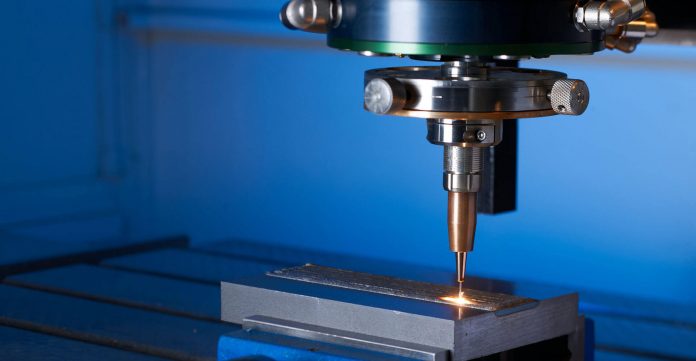

Chiron explains that, unlike other metal AM machines, the deposition head of the AM Cube can be changed during an active Additive Manufacturing/ coating process. This option enables the AM Cube to be used to combine different process requirements; for example, one deposition head could be used to achieve a high surface quality, and another could be used to achieve a high deposition rate.

The automatic head change function enables these properties to be combined in a single workpiece. The AM Cube is equipped with a total of three deposition heads, and both wire and powder can be applied as deposition materials within a single manufacturing process in different production phases.

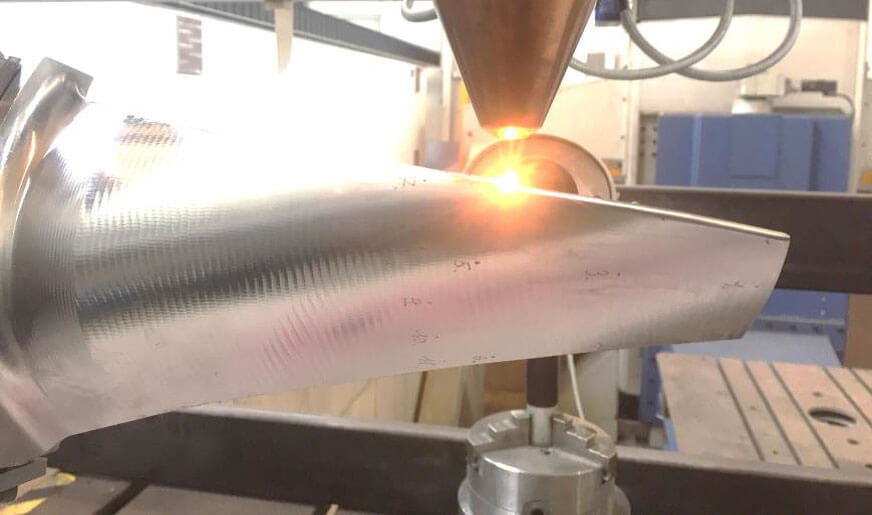

By designing an AM machine for the two commonly used deposition materials – wire and powder – the group states that it has also patented a “completely new technology.”

Both processes have their applications: while coating with powder is the most commonly used process, wire-based laser metal deposition offers better safety characteristics and a reduction in waste material. The use of wire as a feedstock also has the benefit of enabling every type of welding wire to be used.

The AM Cube system can reportedly be reconfigured from 4-axis to 5-axis machining with relatively little effort. It is equipped with cutting-edge sensors and is said to meet all relevant safety requirements for operation without operator monitoring. Chiron explains that where the AM Cube is used to machine particularly reactive materials such as titanium, the entire system can be flooded with protective gas to reduce oxidation, enabling manufacturing to be performed under a protective gas atmosphere for several hours.

The group states that, in order to ensure the suitability of its new solution for industrial applications, an intensive field test of the AM Cube is currently being performed by a pilot customer. The AM Cube will be included as one of the product highlights presented by Chiron during the company’s Open House Online, a digital event set to take place from May 14–19, 2020.

“The Additive Manufacturing department is a start-up within our own business group,” stated Axel Boi, Head of Additive Manufacturing at the Chiron Group. “With this 3D metal printer, made by Chiron, we are creating a facility for manufacturing larger components with long procurement times and high material prices. This technology can be used effectively in mechanical engineering, tool manufacturing, energy production, and aerospace sectors. These are all important target sectors for the Chiron Group.”