The Global Additive Manufacturing and Materials Market was valued at USD 16.6 million in 2020 and expected to reach USD 70.92 million by 2026 and grow at a CAGR of 27.5% over the forecast period (2021 – 2026).

Market overview

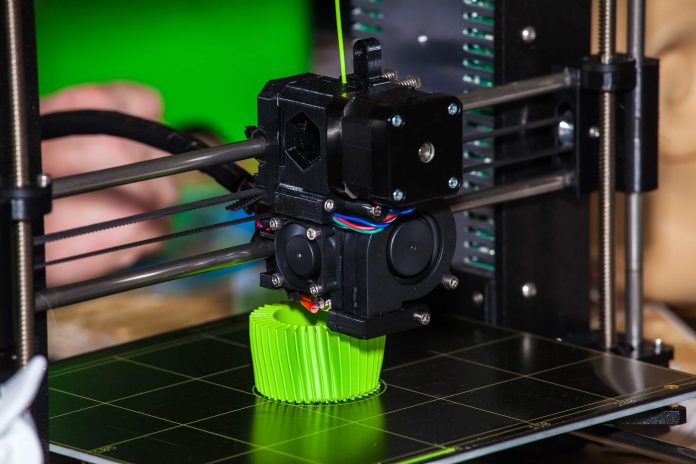

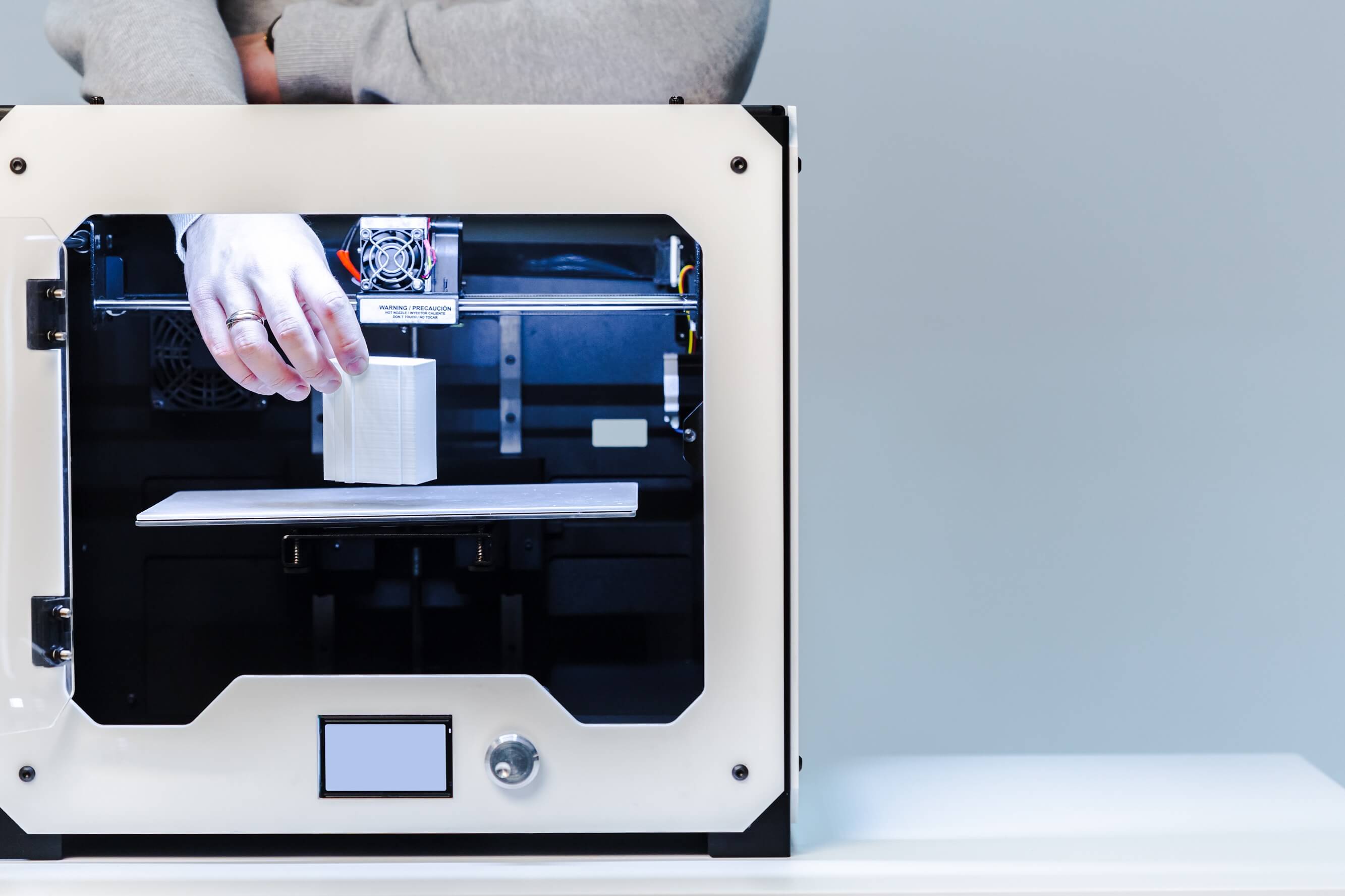

Within the past few years, additive manufacturing has experienced the rapid rise of needed technologies. New advancement in used materials and machines, software solutions and other, made additive manufacturing accessible to a broader range of industries.

The prices of additive manufacturing machines had decreased and the overall availability of these technologies has risen.

The use of new materials over the recent years has enabled the adaption of this technology among various industries.

Materials are advancing every day, and costs per part are decreasing every day which opens new opportunities for different applications. Leading manufacturers are leveraging additive manufacturing to save money, shorten the lead times, solve complex problems, and improve processes from prototyping to production.

According to Essentium’s survey in March 2019, the number of manufacturers using additive manufacturing for full-scale production doubled in 2019, as compared to 2018. Wider adoption of this technology was observed across multiple sectors, as an increased number of industrial solutions were brought to market by manufacturers.

Multiple industries, including healthcare, automotive, and aerospace and defense, are experiencing impactful production and business transformations in the critical areas of their businesses, owing to the maturity of additive technologies and material supply chains. Moreover, additive manufacturing provides design freedom to experiment with more effective and efficient part shapes, with fewer potential points of failure.

Market trends

The automotive industry is the fastest industry when talking about adopting additive manufacturing and that is why it is expected to hold a significant share.

There are various projects and initiatives aimed at bringing the advantages of this technology to automotive applications.One such promising project is the ‘Industrialization and Digitization of Additive Manufacturing for Automotive Series Processes’ project (IDAM).

Launched by BMW Group, this project aims to provide at least 50,000 components per year in mass production using AM, and over 10,000 individual and spare parts.

The Asia-Pacific region (APAC) is transforming into the fastest-growing 3D printing market, with China on the lead.

Until recently, the region has been lagging in 3D printing’s adoption, in comparison with North America and Europe. However, growing interest from Asia Pacific manufacturing companies and the introduction of many government-led strategies and policies have helped several countries within the region to succeed in creating a sustainable AM ecosystem.

The additive manufacturing and materials market is quite competitive and consists of major players like Stratasys, ExOne and 3D Systems Corporation. However, in terms of market share, there are few major players dominating the market. Some companies in the market specialize in the production of machines that make concrete items. In contrast, others are concentrating on materials, which is one of the critical areas of innovation for this technology.