Starrag aims to provide both the cell and software needed to live up to the standards of Industry 4.0. A selection of their machines will be present at EMO show in Hannover.

While Starrag will have at least three machines on show including the just announced Starrag NB 151 machining centre which we mentioned in our report, designed specifically for machining aircraft impellers and blisks, the staff on hand and the technologies on show at EMO will also reinforce the company’s ethos of “Engineering precisely what you value”.

Starrag’s success policy across all its product lines – Berthiez, Bumotec, Dörries, Droop+Rein, Ecospeed, Heckert, Scharmann, SIP, Starrag and TTL – in companies of every size and across all industry sectors, has been built on providing machining solutions tailored for individual customer needs.

This extends from a stand-alone machine with, for example, bespoke workholding and tooling solutions as well as certain spindle and machining head options such as those required for single set-up multi-tasking machining that may involve milling, boring, turning and grinding.

And it extends through to fully automated flexible manufacturing systems with multiple machines complemented by sophisticated workpiece handling/transport options.

At EMO show will be:

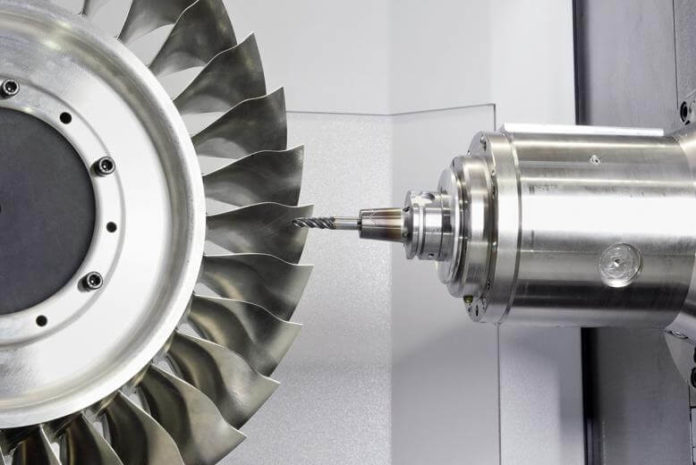

- Starrag NB 151 machine center for blisk and impeller machining

- Heckert T45 five-axis horizontal machining centre with rotary table

- Bumotec s181 five-axis mill-turn centre

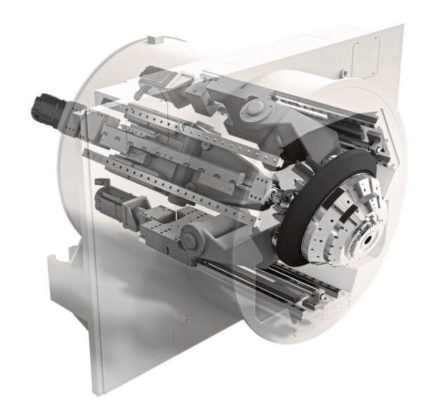

- Sprint Z3 parallel kinematic machining head.