The capabilities for micro-machining have recently been aptly demonstrated by AMRC engineers who have used the mill-turn machine to reproduce a series of tiny portraits of Queen Elizabeth II.

It is a major achievement for University of Sheffield Advanced Manufacturing Research Centre (AMRC) engineers Emma Parkin and Joe Thickett who wanted to create the miniature artwork to demonstrate the AMRC Machining Group’s capabilities with the goal of bolstering industry knowledge on micro-machining to help UK firms win business.

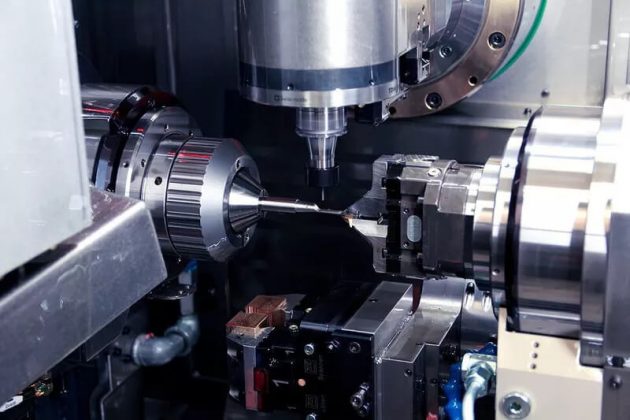

Supplied by Starrag UK, the Bumotec s191 was used by Emma and Joe to produce four highly-detailed Queen’s heads with diameters of 11.2 mm, 7 mm, 2.8 mm and 1.4 mm on a single circular piece of brass of 25 mm diameter. They used Sandvik micro end mills to achieve the basic shape of the design before switching to tiny ball-nose cutters for the detailed contouring.

“We chose Her Majesty as a portrait because we wanted to do something similar to a coin as it is relatable,” says Emma. “People generally know the size of a coin. We wanted to show our partners and wider industry what is achievable; that we can work to an accuracy of 0.001 mm on workpieces as small as 1.5 mm and maintain detail.”

The Bumotec s191H machining centre with 65 mm bar capacity, bar feed system and high-pressure (3 HP) coolant can achieve highly accurate (to +/- 2.5 microns) machining solutions within its X, Y and Z axes range of 410 mm, 200 mm and 400 mm, respectively, courtesy of linear drives and high-level thermal stability.

In addition, its main spindle is complemented by a sub-spindle that can turn in both horizontal and vertical planes, for multi-process/tasking routines. Tool magazine options extend to up to 90 pockets on a machine that has rapid traverse rates of 50 m/min and a 30,000 (or 40,000) revs/min spindle speed that also contribute to its ultra-fast cycle times. Complementary to such an impressive machine specification, Emma drew on the vast expertise within the AMRC to create the micro-machined portraits.

Downsizing Her Majesty

“To get Her Majesty’s face, we scanned a real coin using a 3D microscope that’s normally reserved for detecting surface roughness. It took a series of pictures which were ‘layered up’ to create a 3D image — and that, in turn, was turned into a STL file format. That was then uploaded into Siemens NX 12 CAD for the generation of the machining program.” She adds: “We started cutting at 4 mm depths to remove the bulk material, then went down in size and when we got to the finishing operations, we were doing micron ‘step overs’.”

Emma is hoping the ‘coin’ demonstrator will lead to further micro-machining R&D and commercial projects for the AMRC, which is part of the High Value Manufacturing (HVM) Catapult network. “I just want people to come and have a look at what we’re doing.”

“At the moment when people come to the AMRC, and here to Factory of the Future, what they generally see are massive aerospace components and huge machines. I want people to also walk onto the shop floor and say ‘wow, the AMRC can make some really small parts. Let’s work with them’.”