Researchers at Oak Ridge National Laboratory (ORNL), Oak Ridge, Tennessee, USA, are reported to have demonstrated that a new class of superalloys, made of cobalt and nickel, remains crack-free and defect-resistant in extreme heat, making them conducive for use in metal Additive Manufacturing applications.

The cracking susceptibility of high-performance engineering alloys, including Ni-base superalloys, high strength aluminium alloys and refractory alloys, has represented a major barrier to the use of these alloys for AM components in critical applications.

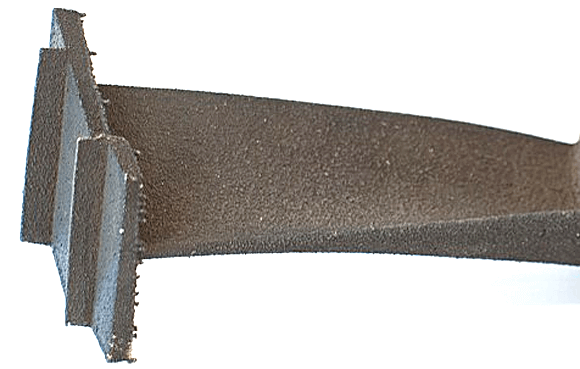

In a study, researchers processed a new cobalt and nickel class of superalloys and proved that they remained crack-free in both Electron and Laser Beam Powder Bed Fusion (PBF-EB) and (PBF-LB) AM processes.

The superalloy, containing approximately equal parts of Co and Ni along with Al, Cr, Ta and W, is said to possess strengths in excess of 1.1 GPa in as-printed and post-processed forms, with tensile ductilities of greater than 13% at room temperature.

“The challenge has been producing alloys that don’t crack in the heat,” stated ORNL’s Mike Kirka. “These superalloys have the material properties necessary for challenging environments, because they not only successfully withstood the heat, but also retained strength when stretched.”