Okuma will make use of the grand stage at EMO Hannover (16-21 September 2019, hall 27/D26) to present highly efficient solutions for the mould and die industry and precision machining along with digitalisation and automation solutions. One highlight will be the newly developed double column machining centre MCR-S (Super) for high-precision 5-sided machining of large workpieces. The industry’s only single-source provider will present a large number of CNC machine tools, software solutions and intelligent controls.

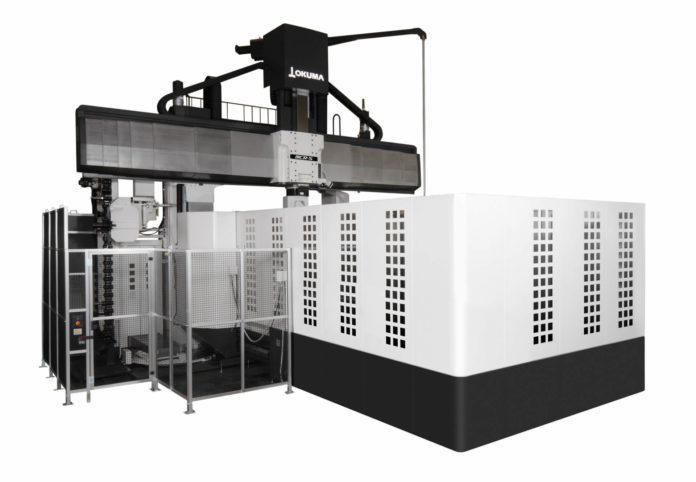

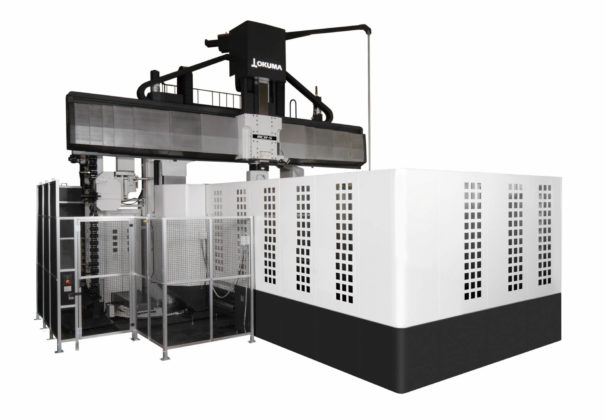

New double column machining centre for highest demands

The new double column machining centre MCR-S (Super) combines several state-of-the-art features and is predestined for producing dies of the highest quality.

Manufacturers benefit from outstanding dimensional accuracy and a very high surface quality. The machine’s robust double column layout ensures stability and provides vibration dampening properties.

As the manufacturing process of dies is very vulnerable to temperature changes, Okuma equipped the MCR-S with the Thermo-Friendly Concept. A swivel image sensor allows for precise measuring at the cutting edge and ensures that all production steps are traceable.

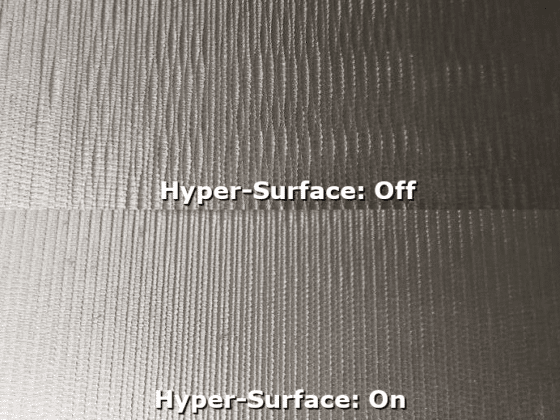

Hyper-Surface makes manual post-processing obsolete and shortens the time needed for processing the raw material. The machine offers very high chip removal rates and achieves outstanding 710 cm/min when face milling.

Rich portfolio for the mould and die industry

In addition to double column machining centres, Okuma offers a large variety of machine tools of great value to the mould and die sector.

At this year’s EMO Hannover, Okuma will also display the affordable 5-axis machining centre GENOS M460V-5AX and the newly developed and smallest vertical machining centre GENOS M660-V-E.

Another highlight will be an MB-46VAE equipped with STANDROID, the latest solution for automation.

STANDROID is a robotic arm installed in a cell. This enables easy setup and integration into the production environment making automation accessible for small and medium sized businesses where conventional technologies would be too expensive and overly complex.

Visitors will also find Okuma’s renowned high-tech multitasking machines of the MULTUS U and LASER EX range.

Digitalisation and Automation

In combination with Okuma machine tools, these Smart Factory solutions offer a substantial added value and represent an important step towards comprehensive automation.

Smart Factory know-how expanded

With a third IoT-based “Dream Site” factory put into service, Okuma further expands its Smart Factory know-how.

The Okuma concept for IoT relies on the latest technological developments and combines big data, artificial intelligence and intelligent production processes. This is true for the controls, Smart Factory technologies and automation solutions.

Digitalisation from the start

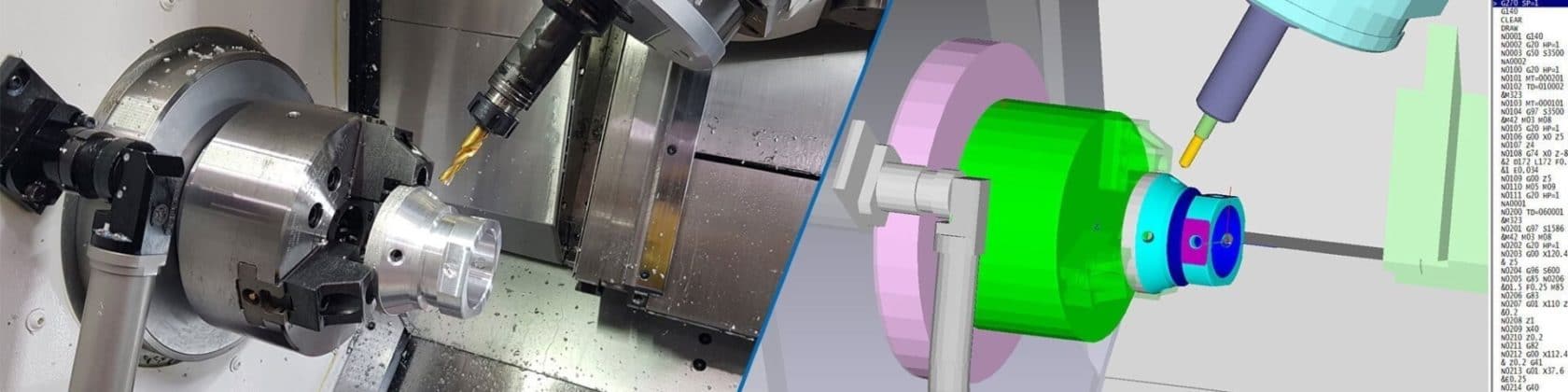

For Okuma, digitalisation starts long before the actual machining takes place. The Okuma technology 3D Virtual Monitor, allows manufacturers to simulate and test the entire machining process in advance.

For a highly accurate simulation of the machine, 3D Virtual Monitor relies directly on the construction data. This avoids, programming errors and setup times are significantly shortened. Additional benefits are safe parting-off operations and reliable handovers of the workpiece.

Comprehensive connectivity made easy

The Okuma software Connect Plan offers valuable real-time updates of all machines in the manufacturing process regardless of where they are located.

This real-time information can be used to analyse and optimise the utilisation of the entire plant. Even machine tools by third-party providers can be integrated into this system.

For traceability, Connect Plan connects each individual identifier with the manufacturing data and the measuring results of every machine involved. If problems occur, they can easily be identified and solved allowing the production to continue with higher quality and more safety than before.

The process data can also be used for Predictive Maintenance in order to plan and predict maintenance intervals. In the EMO booth, Okuma will connect all machine tools via Connect Plan, so that visitors can experience first-hand the potentials of data-driven plant optimisation.

Intelligent control enables digitalisation

The cornerstone of digitalisation is Okuma’s intelligent control, which Okuma develops and manufactures itself as the industry’s only single-source supplier.

The advanced OSP-P300A control is perfectly tailored to the CNC machines and a shared database ensures a boost in efficiency.

Data that is input in one area of the control can be shared automatically. This enables users to avoid unnecessary inputs and set-up times are shortened. Thanks to the open Windows architecture of the control, all Okuma machines can be easily integrated into existing manufacturing environments.

The key to fully automated manufacturing

Complex factory automation relies on state-of-the-art robotics. But automation is gaining importance also for small and medium-sized enterprises.

Okuma offers efficient automation solutions for various needs. At this year’s EMO Hannover, two new automation technologies will be presented that are superior to conventional robots in many ways.

ARMROID is a robotic arm integrated into the machine tool. This opens entirely new possibilities for the machining process and makes automation available to small enterprises.

Okuma continues this path with STANDROID offering a robotic arm integrated into its own separate cell. The cell can be connected to a machine tool, and retrofitting is possible. With these solutions, Okuma makes automation accessible for businesses of various sizes.

Exhibition highlights include:

- Okuma next-generation robot systems ARMROID and STANDROID

- New CNC double column machining centre MCR-S

- Multiple Smart Factory Solutions

- MB-5000HII horizontal machining centre connected via umati (universal machine tool interface)

- MU-5000V-L vertical machining centre connected to BMO Titanium 180 automation cell

For more information regarding Okuma EMO 2019 visit www.okuma.eu