In the dynamic world of precision manufacturing, our company stands out as a leader, specializing in reverse engineering and providing diverse 3D printing services. Focused on innovation and technological excellence, we deliver customized solutions to clients across various industries.

Expertise in 3D printing:

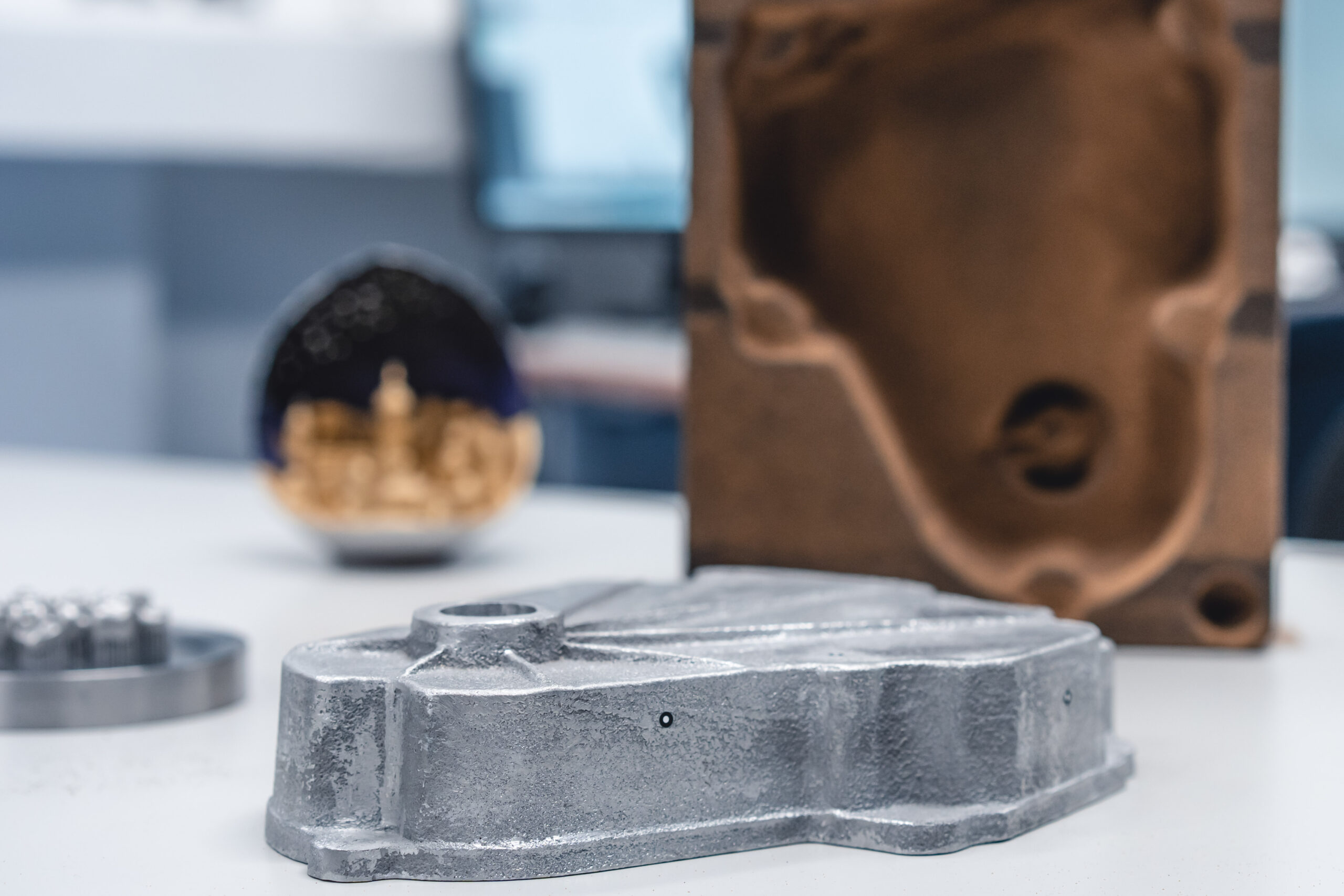

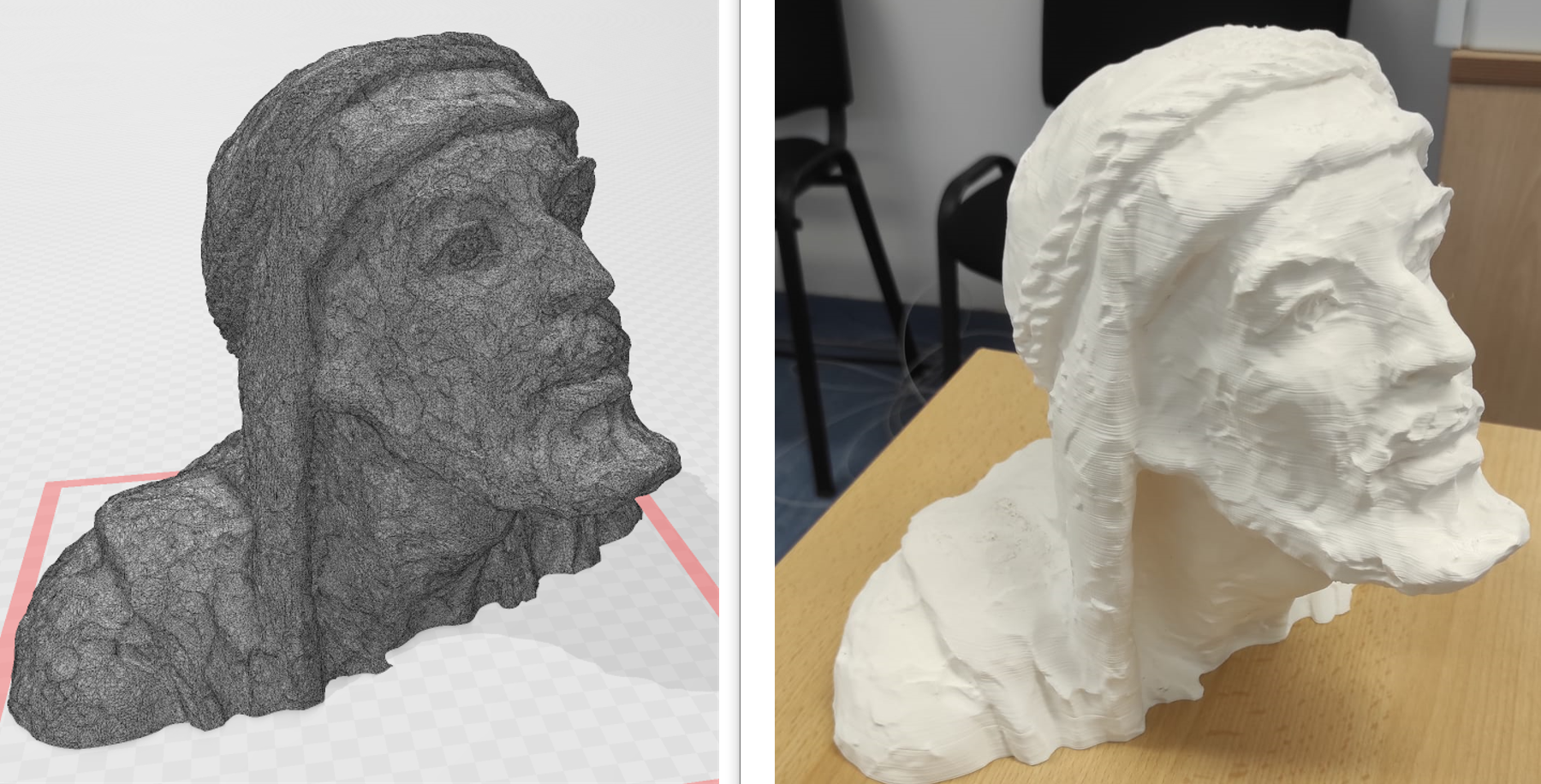

- 3D printing of molds and cores for metal casting: Utilizing Binder Jetting technology, the process combines sand and liquid binder to create precise molds with intricate geometries. This method is ideal for rapidly producing molds for prototypes and research purposes. With the capability to 3D print molds and inserts up to dimensions of 300 × 200 × 150 mm, we achieve an impressive layer resolution of up to 300 dots per inch (DPI) and layer thickness of up to 300 µm.This technology is suitable for the production of:

-

-

-

- molds for casting various metal sculptures, such as bronze busts.

- molds for casting prototypes of machine and device parts.

-

-

-

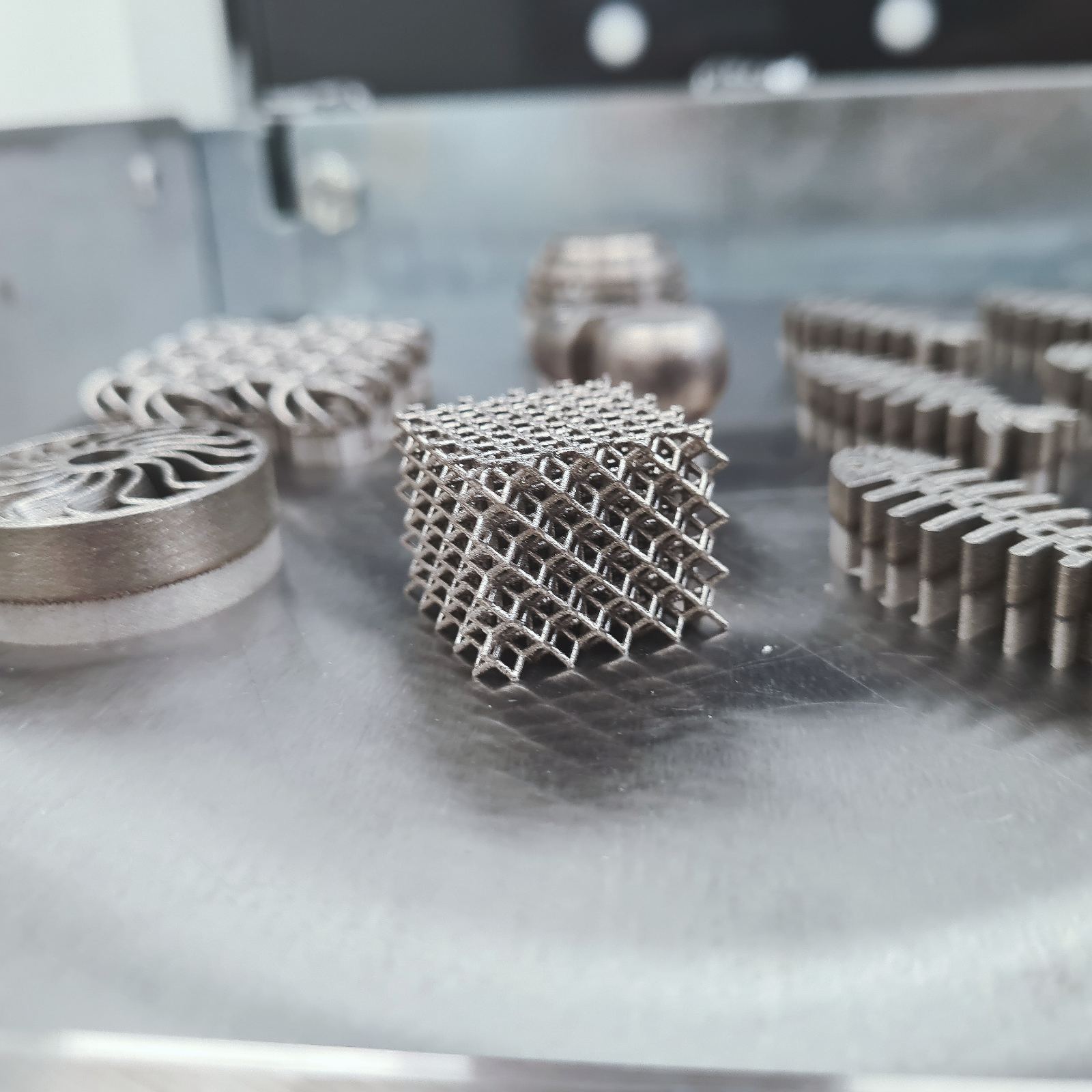

- Direct Metal Laser Sintering (DMLS): We manufacture parts from tool steel, stainless steel, aluminum, titanium, and cobalt chrome. With dimensions up to Ø 100 × 95 mm for cobalt chrome and up to 250 × 250 × 325 mm for steel, aluminum, and titanium, we provide precision with layer thicknesses of up to a maximum of 10 µm.

Laser sintering enables us to:

-

-

- manufacture tools and machine parts from very hard metals that are difficult or impossible to machine using conventional machining methods

- manufacture of orthopedic aids, artificial joints in orthopedics, and components of artificial teeth and jaws in dental medicine

- manufacturing parts with complex geometries, such as lattice and hollow structures with internal channels, heat exchangers, parts generated through artificial intelligence for improved mass-strength ratios, organic shapes, and similar applications

-

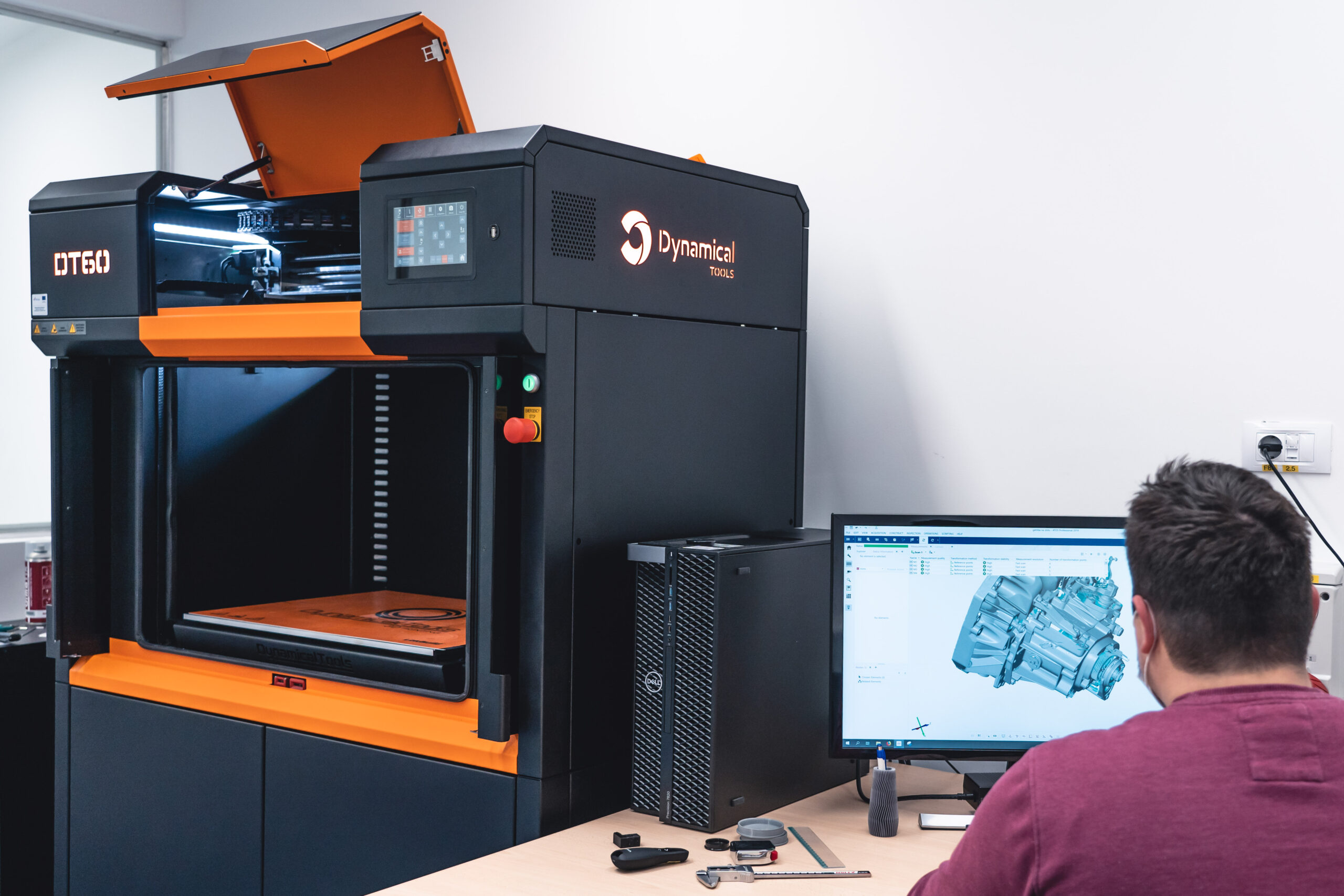

- 3D printing of polymers (FDM): Using an industrial 3D printer, we can manufacture polymer parts with dimensions up to 600 × 450 × 450 mm. The printer features a heated chamber up to 120 °C and a nozzle heated up to 500 °C, enabling 3D printing of engineering materials such as PETG, ABS, TPU, and PA12CF.

Our industrial 3D polymer printer can:

-

-

- produce prototypes of much larger dimensions than standard printers

- manufacture objects from a wide range of materials within a stable, heated chamber atmosphere

-

efficiently produce prototypes with two types of materials or two colors, thanks to the dual extruder.

-

Membership in the 3D Printing Hub:

The Rijeka Development Agency Porin, alongside Metalska jezgra Čakovec and the Entrepreneurial Incubator BIOS, is a proud founder and member of the consortium 3D Printing Hub Croatia. This consortium enables entrepreneurs to achieve rapid development of high-quality and precise prototypes, as well as the production of smaller product batches.

Additionally, the locations of the founders (Čakovec, Rijeka, and Osijek) allow for the provision of high-quality services and support to entrepreneurs throughout the country. The fundamental services offered by 3D Printing Hub Croatia to entrepreneurs include 3D scanning, 3D modeling, 3D printing, and post-processing on industrial equipment, which also encompasses precise measurement services and reverse engineering.

This strategic collaboration enables us to leverage shared knowledge and equipment, fostering a collaborative environment where advanced technologies seamlessly integrate into our manufacturing processes. This collaborative approach allows us to provide innovative solutions and a broader range of services to our clients, raising the standards of 3D printing within our collaborative network.

If you would like to discover how the Torpedo Manufacturing Park and the Rijeka Development Agency Porin can enhance your business, please contact us via email at pptorpedo@porin.hr or rraporin@porin.hr, or by phone 051 634 331.

For inquiries about the services of 3D Printing Hub Croatia, please reach out to us at info@3dprintinghub.hr or visit our website.