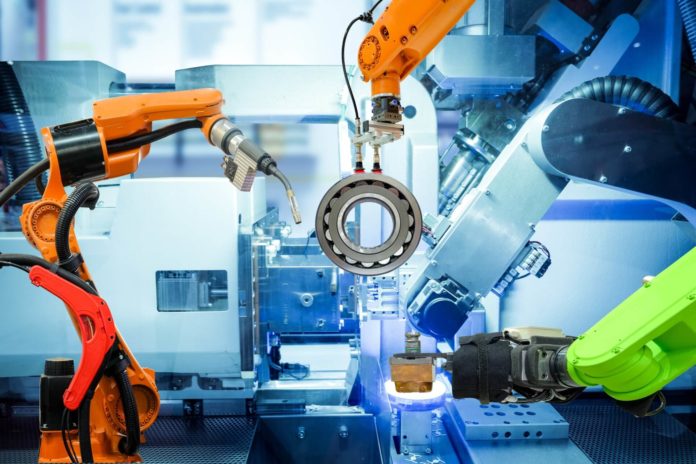

Small, compact robots could allow manufacturers to be more agile, flexible and versatile. Being able to utilise this technology could offer up new opportunities and scope for businesses.

The benefits of mobile robots are numerous. Compact robotics can reduce security issues, improve flexibility and agility in business, and are rapidly improving technology. Also they can reduce security issues, improve flexibility and agility, and are rapidly improving technology. Compact robotics can reduce security issues, improve flexibility and agility in business, and technology that is rapidly improving.

As these machines become more efficient, they become more accessible and more flexible with the ability to adopt and scale in different storage environments.

Machines can complete recurring exercises and take alternative travel routes during production to move products between workers and stations, ultimately improving operations.

By combining problem-solving abilities and adaptability with repetitive tasks robust endurance robots can help factories become more flexible. This is, of course, particularly important for production, where more and more products with higher diversity and smaller production sizes are produced. Autonomous mobile robots can also offer new inventory tracking capabilities. Mobile machines can now independently run their own scheduled inventory by companies

Case study: FANUC slimline robot

FANUC has announced the expansion of its new generation of compact general purpose robots The M10iD / 10L is the latest model from the M-10 robot series.

Delivered with a long handle up to 1636mm. With a 343m x 343mm print, the robot is suitable for compact production lines, and is articulated to reach tight spaces.

The compact part of the automation has a hollow hand, wrist and body, making it easier to router the internal cables. The company believes it makes the robot easy to integrate and modify, but – along with thin bent arms – also reduces any interference with peripheral devices.

Mobile Robotics Integrated in Retail

ABB’s Cooperative Robot, YuMi, was tested because it is currently located in the London Selfridges store.

The double-handed cobot, whose name is the abbreviation of “You and Me”, will serve the customers of freshly prepared coffee, thus taking over the role of the waiter.

Making and serving coffee is just one of the many tasks YuMi can handle for ABB, since the cobot was originally intended for small parts assembly.

Compact robotics can reduce security issues, business flexibility and agility, and are rapidly improving technology.

Kobot’s technical capability includes a mix of functional and safety features, from motion control software to ergonomic, lightweight design. These include high-precision tasks such as connecting smart phones, wrapping clocks, or fine electronics to EV.

Kobot’s technical capability includes a mix of functional and safety features, from motion control software to ergonomic, lightweight design.

YuMi can also be equipped with visual systems, tactile grips and feedback that controls the sensitive force that enables it to effectively see and feel the objects it manages.

Source: themanufacturer.com