The new releases of FASTEMS LLC’s Gantry Tool Storage (GTS) system and Manufacturing Management Software (MMS) are designed to deliver significant increases in manufacturing efficiency, enhance ergonomics, and improve overall user experience.

When applied within a Fastems Flexible Manufacturing System (FMS), the GTS system and MMS can achieve machine utilization levels above 95%.

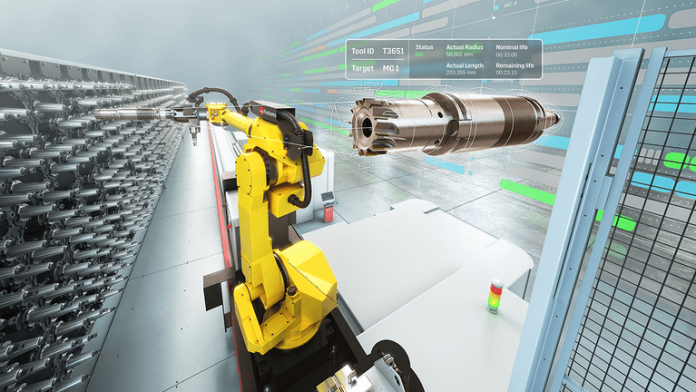

In the GTS system, pick-and-place and traveling gantry robots provide access to centralized storage of up to 4,000 cutting tools and perform just-in-time tool delivery to individual machines.

MMS software commands automatic cutting-tool changes based on specific NC program scheduling requirements and real-time cutting tool life status.

The GTS system enables cutting tools to be shared among multiple machines, minimizing redundancy, and eliminating the need to reserve a cutting tool for a single machine. This generates cutting-tool cost savings and minimizes operator interaction with cutting-tool changes, reducing labor expenses, and eliminating tooling loading errors. Cutting-tool sharing also permits a reduction in the size of machine tool magazines.

When implementing the GTS system, its new modular design results in shorter delivery, installation, and commissioning times, as well as hardware cost advantages.

Improvements to MMS software include a more ergonomic interface and improved user experience, faster-cutting tool information search functions, improved view of NC programs, and upgraded response in the case of unexpected machine stoppages.