Edgecam 2021 from Hexagon Production Software is designed to boost productivity with lower computer processing time and faster tool paths.

Many of the productivity increases come from the software’s improved parallel processing capability and multi-threading algorithms. Thanks to these processing improvements, the high-speed waveform roughing strategy is now significantly faster when generating tool paths for both solid and wireframe components, the company says.

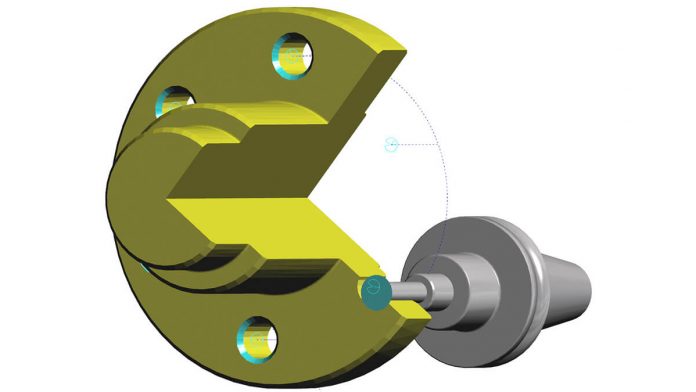

When using the profiling cycle’s Undercut function, savings of between 40 and 60% have been recorded, depending on part size and complexity. Additionally, improvements to the software’s architecture reduce the time it takes to check tool paths with Machine Simulator when the software is initially launched.

A probing functionality overhaul revolves around eight new cycles, which deliver support for programming on-machine probing. The cycles’ NC output can be configured to support Hexagon’s existing m&h probing macros as well as other popular probing systems for different controls and native probing languages for Siemens and Heidenhain controls. Six new or updated commands have been introduced into the inspection operation, including the ability to globally edit existing features and another to control the layout of both linear and rectangular array features.

The Cut by Region option deploys a more even tool path, completing each segment of a component before moving on to another region. The Outside To In strategy reduces cycle times by maintaining closer cutter contact, whereas previously a face mill would take longer in Climb or Conventional mode to move left to right in readiness for the feed movement.