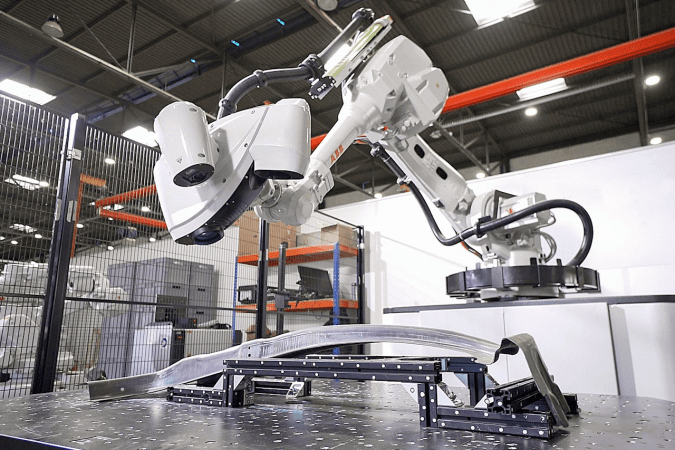

Based on structured light and photogrammetry, ABB’s new 3D Quality Inspection (3DQI) cell is capable of measuring at a pace that is dramatically faster than traditional measuring inspection tools. 3DQI not only offers quick and accurate quality checks, but also reduces expensive rework and scrappage.

The scalable quality inspection cell accelerates production for the automotive, aerospace, heavy machinery and construction sectors, enhancing quality and productivity.

ABB’s 3D quality inspection (3DQI) robot cell will dramatically accelerate production by providing fast, accurate testing to make metrology easier and less time consuming. The 3D Quality Inspection cell eliminates the need for time consuming manual inspection, while substantially reducing the likelihood of faults and errors. As well as increasing productivity, the solution also reduces costs by minimizing the risk of product defects that could lead to potential recalls.

Key benefits of the 3DQI cell include its combined speed, accuracy to below 100 (micrometer) μm and flexibility provided by its modular design, with customers able to create a solution tailored to their exact requirements.

The 3DQI is conceived for offline testing stations and its modularity allows customization or expansion to meet evolving business needs. Using a single 3D white light optical sensor to scan millions of 3D points per shot, a detailed digital model of the part being inspected can be created which can be compared to an original CAD drawing. All of this can be done 10 times faster than with traditional Coordinate Measuring Machines (CMM).

The sensor can be carried by any robot with a handling capacity greater than 20 kg and is compatible with a range of robots, tracks and rotary tables, so there are no limits on the dimensions of the parts that can be inspected. The new 3DQI inspection cell is the latest cell introduced by ABB and joins FlexArc and FlexLoader in ABB’s growing portfolio of smart, flexible solutions.

“The ability to accurately measure and control quality is vital to ensure that products achieve consistency, comply with standards, and meet customer expectations. Traditional testing methods are slow and capture the potential quality mistakes often too late in the process,” said Tanja Vainio, Managing Director Auto Tier One Business Line for ABB Robotics.

“Our 3DQI cell automates this process, far exceeding the capabilities of traditional inspection in speed, accuracy and repeatability. We’ve developed and piloted our 3DQI technology in automotive applications, including automotive supplier Benteler, and the 3DQI solution has been proven to improve product quality, throughput and safety, while freeing up skilled labor to be deployed on other tasks.”

The solution also provides comprehensive data analysis processed in real time. Digital records support traceability, which is needed in several industries, as well as enabling customers to adapt their processes to prevent further failures to improve overall quality and productivity. All equipment is included in ABB’s powerful RobotStudio Sidio Planner Power Pack for easy and intuitive programming, enabling new users to quickly become familiar with using the 3DQI solution.