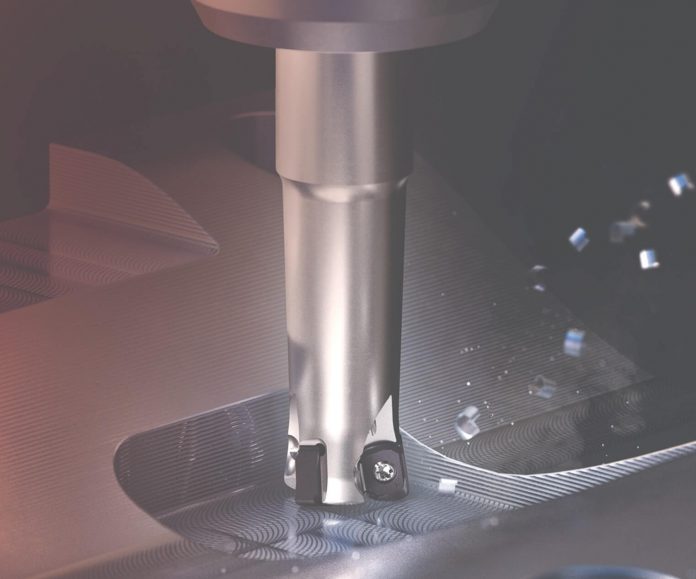

YG-1’s ENMX High-Feed Mill 4 is a series of small-diameter cutting tools developed to meet stringent demands of versatility, productivity and process stability.

The ENMX insert’s thickness allows normal flank wear to develop without encroaching on the secondary edge, resulting in the full use of all four edges, the company says. Thicker inserts also clamp more securely, the company says, ensuring predictable and secure machining and longer tool life in difficult applications.

The thicker negative insert has a positive rake angle that improves chip evacuation and reduces machining load. The corner protection design is said further to enhance rigidity while increasing tool life in combination with the chipbreaker’s optimized geometry.

The ENMX cylindrical cutter is available in diameters ranging from 16 to 32 mm (0.75″ to 1.25″). Shell mills are available in diameters ranging from 40 to 50 mm (1.5″ to 2″).