Manufacturing is on the eve of comprehensive digitizing, which in one way or another will impact almost all its stages: product design, process planning, machining, assembly, and more. The driving force behind the changes is a series of technological breakthroughs related to the fourth industrial revolution, known as Industry 4.0.

With the use of network communication, new digital technologies combine physical manufacturing systems with virtual worlds of knowledge and 3D modelling. The target is significantly increased output but as manufacturing systems considerably improve their intellectual features and decision-making capabilities, they necessarily become more complicated and more expensive. Minimizing the downtime of such systems is a “must” for the development of every system component such as machine tools, workholding device or a cutting tool.

Cutting tools can not only cut metal but also cut downtime, depending on their design concept.

Assembled cutting tools with exchangeable cutting heads from cemented carbides are very common in metalworking today. If two decades ago there were very few systems built on an exchangeable head principle, now practically every leading cutting tool manufacturer has this type of system in its product range.

Advances in tool grinding and resharpening machines have simplified production of solid carbide tools and their regrinding. This in turn has resulted in an increased number of medium and small tool manufacturers, and a growth of regrinding services. It might have been expected that the solid carbide design approach would seriously challenge the exchangeable alternative and quickly regain lost ground. However, this has not happened and, in fact, the situation is reversed: progress in machine tool engineering and the current trend towards smart manufacturing hold good promise for the future of assembled cutting tools with exchangeable heads.

An example of this apparent contrast may be provided by taking a look at ISCAR – a leader in the field of cutting tool manufacturing. ISCAR introduced the “no setup” principle in tools with exchangeable heads, whereby replacing a worn head would not require any additional setup operation for adjustment, and therefore the head could be changed without removing a tool from the machine. The source of this “no setup” feature is high repeatability of the exchangeable heads that is ensured by a face contact between the head and a tool body, and strict tolerance limits for the head area protruding over the body.

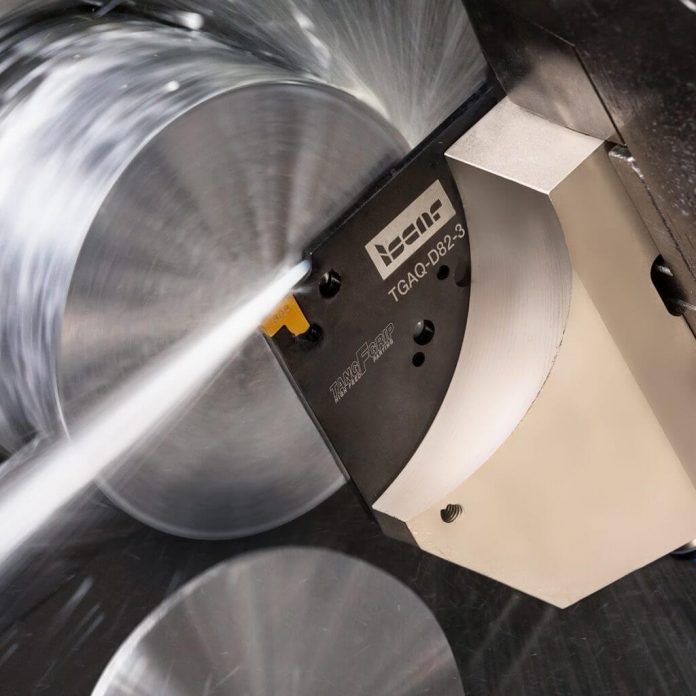

The “no setup” principle was successfully realized in ISCAR’s MULTI-MASTER and SUMOCHAM rotating tool families. In non-rotating products, the new MULTI-F-GRIP and LOGIQ-5-GRIP parting and grooving tool families represent the fruits of a different approach where the assembled tool comprises a tool block and an indexable multi-pocket adapter carrying replaceable inserts. Due to the high precision of the assembly components, the pocket indexing does not require additional setup. Both “no setup” concepts provide significant reductions in machine downtime.

Along with the benefits in reducing downtime, these tools feature exceptional versatility. The MULTI-MASTER, for instance, where the head is suitable for mounting in different tool bodies, and the body can carry different heads, enables thousands of tool combinations for a broad range of applications, including milling shoulders, faces, slots or complex surfaces and machining holes or chamfers. MULTI-F-GRIP, a family of non-rotating tool blocks and 4-pocket adapters, integrates both TANG- and DO-GRIP inserts. Not so long ago, versatility was considered as the main advantage of the tools with exchangeable heads; however, recent progress in machine tool building and, especially, the trend towards smart manufacturing based on Industry 4.0 concepts, returned “no setup” capabilities to the fore.

Advanced regrinding allows restoration of cutting geometry of a worn solid carbide tool with high accuracy. However, the tool changes dimensions; and putting it into operation demands preliminary setup and appropriate corrections in a CNC program. This causes a reduction in effective cutting time, diminishing productivity which in turn increases production costs.

However, a “no setup” quick-change cutting head eliminates the need for supplemental measurements or program corrections and does not require any additional setup units. This is why the “no setup” capability of a cutting tool plays a significant role in a smart metalworking factory. From this point of view, “no setup” assembled tools with exchangeable carbide heads, such as MULTI-MASTER and SUMOCHAM, can be considered as a good match for a smart factory. Understanding the benefits of this capability makes it clear why ISCAR considered tough tolerance limits for the overhang as an essential design requirement when the company started development of these two lines, some twenty years ago.

A further advantage of using tools with exchangeable heads is their ability to customize tool configuration according to the requirements for machining a specific part. Multitasking machines that enable various types of cutting in one single-step process have become very popular in industry. These machines have driven-tool capabilities for combining machining by rotating and no-rotating tools, which can significantly improve productivity. In addition, machine tool builders offer a range of options to supplement a standard CNC lathe with driven-tool functions, and so transform the lathe to a multitasking machine.

The power characteristics of a typical driven-tool unit are similar to the parameters of a typical small machining center. The MULTI-MASTER line features a wide variety of tool bodies (“shanks”) with different adaptations, reducers and extensions, which ensure an optimum configuration and minimize tool overhang. This greatly contributes to reducing bending load on the driven tool unit mechanism to improve performance and tool life.

Implementing Industry 4.0 concepts into the metalworking industry is exemplified by the integration of the “no setup” principle in assembled tools with exchangeable heads. And it is not only about saving cemented carbide; the new developments have generated important capabilities to maximize machining output and decrease production costs.

At the same time, it is precisely these capabilities that might demand stricter requirements for appropriate design parameters, particularly regarding the tightening of axial repeatability tolerances.