Many materials with high ductility and tendency to stick are always a challenge in machining. Problems with the chip flow are in most cases the performance-limiting criteria.

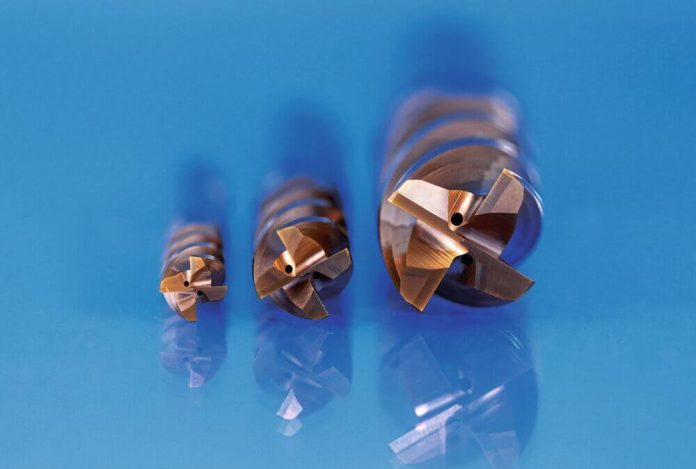

To generate process reliability and machining performance for this application area, Jongen Werkzeugtechnik GmbH has developed the 4-edged solid carbide milling cutter type VHM 479W HD08.

The miscellaneous application areas are step milling, contour milling, full slot milling, ramping up to a plunging angle of 29°, helix milling, as well as trochoidal milling and at the same time these Jongen Uni-Millsolid carbide cutters are suitable for roughing, as well as finishing operation, thus they are universally applicable.

Due to the stable but still open, 4-edged construction, this tool type is particularly suitable for the economical processing of materials that normally cause problems due to poor chip evacuation, when using traditional tool designs. This is relevant for example for the machining of inox, difficult-to-mill materials, such as nickel-base alloys and titanium, as well as for the machining of steel materials up to medium strength properties. This tool type has been designed especially for these application areas.

Four generously dimensioned profile grooves in combination with a stable basic construction and a positive cutting edge geometry, with a special cutting edge preparation are the properties that make this tool type so powerful and resilient.