Insert indexing and chips can bring your high-volume, small-part turning operations on Swiss-style machines to an immediate halt.

Constrictive work spaces and multiple tools situated in extremely close proximity to one another make insert indexing difficult, time consuming and inefficient. At the same time, poor chip evacuation leads to reduced tool life for toolholders and cutting inserts.

Eliminate inefficient indexing

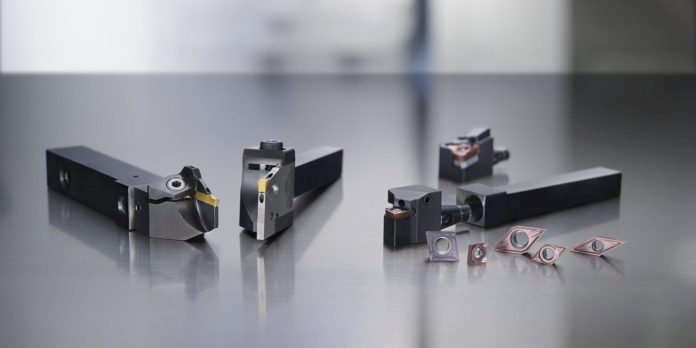

Tight machine work spaces make accessing and removing screws very difficult. Because of its modular design, the Modular QC Toolholder eliminates the difficulty of indexing small inserts as the system allows you to change the insert outside the machine which reduces the risk of very small screws and inserts dropping down into the machine.

Keep chips from stopping your production

Chips can hinder unmanned small-part operations on Swiss-style machines and continuously cause production stoppages. Efficiently evacuate chips with Seco Jetstream Tooling® and Seco Jetstream Tooling® Duo technologies incorporated into the Seco Modular QC Toolholder.

Benefits:

- Repeatability due to tight tolerances on the interface

- Secure single lock system makes it easy to use

- Predictability tool life with Seco Jetstream Tooling®

- Multiple heads fit on a single shank offering versatility

- Precision insert positioning due to patented carbide pin pocket design

- Productivity increased due to less machine down time between tool changes