In order to meet customers’ needs, the product range at Meusburger is constantly being expanded — like the workshop equipment range in mid-October.

New innovations have been added to the product groups surface finishing equipment, assembly equipment and clamping equipment, and there were expansions in the areas of cutting tools and EDM accessories.

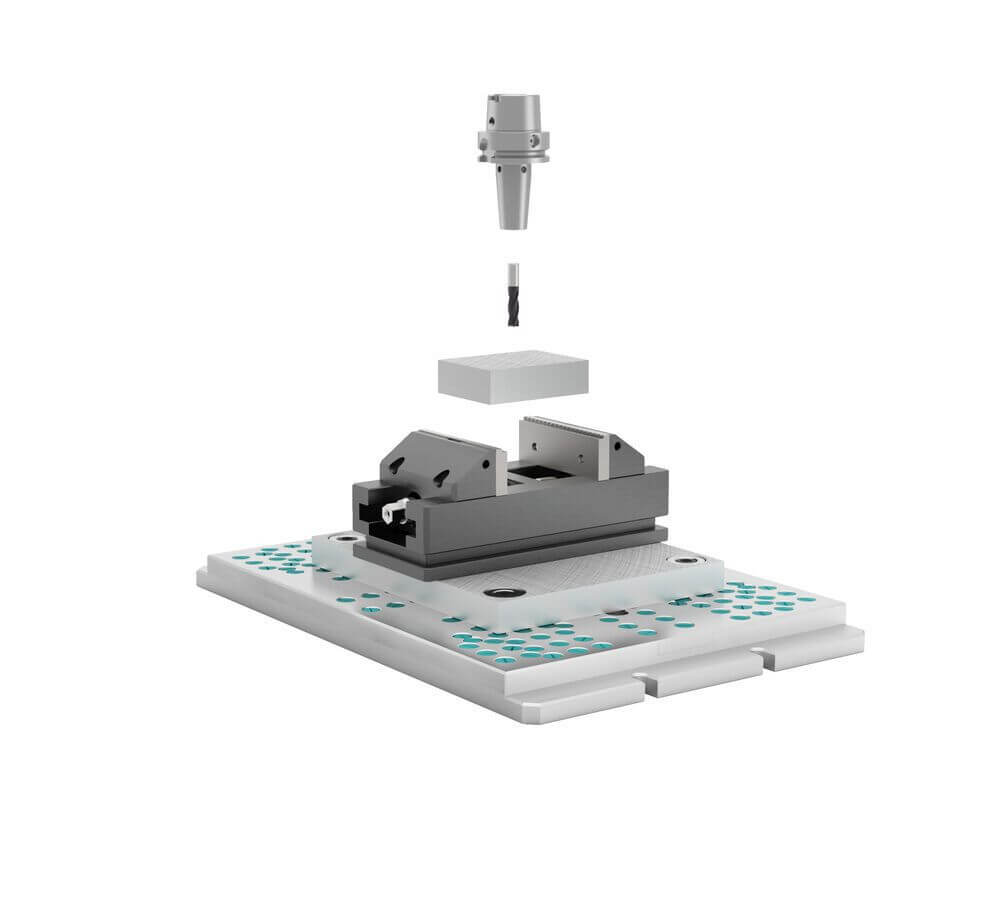

HWZ Tool holders

The new tool holders in HSK-A 63 hollow shank taper and SK 40 steep taper variations offer the perfect connection between our cutting tools and your machine. They are especially ideal for clamping Meusburger milling and drilling tools. The tool holders have been used in Meusburger’s own series production for quite some time and their process reliability and quality are tried and trusted.

Coordinated to the mould and die making industry, a wide range of standard parts including accessories is available as usual from stock. Thanks to the tool holders, Meusburger is now a full-range supplier for equipping machine tools in the cutting processes.

M-Line micro motor system

The stationary GESM 1000 control unit automatically detects the type and maximum speed of all M-Line micro motor handpieces. The system has a 4.3“ colour display with speed and load display. The speeds are infinitely variable from 1,000 – 80,000 min-1.

Alternatively, the mobile GESM 1500 battery-powered control unit allows for flexible and mobile use of all M-Line micro motor handpieces. The high battery capacity and speeds from 4,000 – 40,000 min-1 enable best performance. Seven different handpieces are available for almost any application.

V 20435 Diagonal cutters for plastic

The V 20435 diagonal cutter for plastic with 15° cutting edge is ideally suited for the flush cutting of sprues and burrs on plastic injection moulded parts. This is now available from Meusburger with cutting edge protection in the lengths 130, 160, and 190 mm.