Okuma, a specialist in CNC machine tools and process optimisation, working together with Dr. Kaiser Diamantwerkzeuge, has developed a new control app for CNC programs.

The Okuma Dressing App is one of the most innovative dressing technologies on the market. It is highly efficient and extremely easy to use.

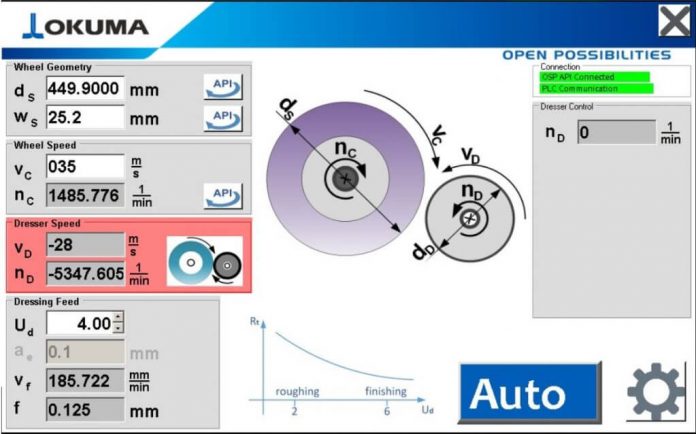

The control application calculates all dressing parameters, independently reads the available data and transfers the values directly to the CNC program. Manual calculations and double entries are now things of the past.

What matters most is selecting the right dressing parameters, such as dressing speed ratio or dressing feed rate. Working in conjunction with Dr. Kaiser Diamantwerkzeuge, Okuma analysed the possibilities already offered by existing apps and the parameters needed to further optimise the grinding process. The realisation: above all, what was missing was user-friendliness and efficiency.

The Okuma app can be opened and operated directly from the main screen of the controller. The user only has to enter the geometry of the dresser and the desired values for speed ratio, infeed depth and overlaying amount. The app then automatically transfers to the CNC program the values for feed rate and cutting depth, the dressing speed and the direction of rotation is directly transferred to the Dr. Kaiser inverter.

The app had to prove its functionality in a test cut. It passed with flying colours. The control automatically read out the grinding wheel speed and diameter and from these calculated the peripheral speed. The app used this value to determine the speed of the dressing wheel, with reference to the selected speed ratio.

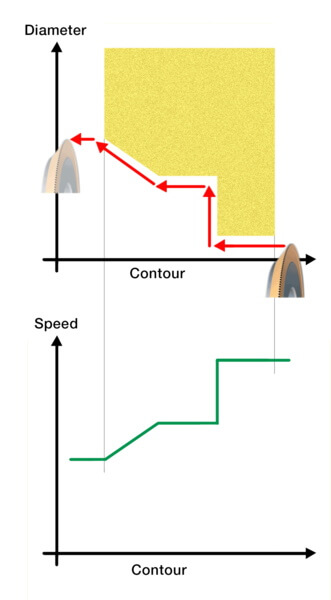

This means the app can create constant cutting conditions over the entire grinding wheel and keep the speed ratio constant even with large steps in the contour.