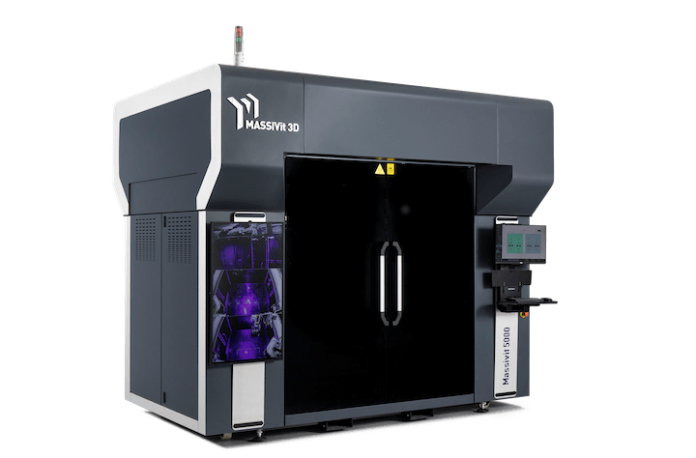

Large-format 3D printer manufacturer Massivit 3D Printing Technologies has unveiled its latest machine at the AMUG 2021 Conference last week.

With a huge build volume of 145 x 111 x 180 cm, the Massivit 5000 has been developed for manufacturers and service providers, particularly those operating in the automotive, marine and rail industries, who are looking to accelerate lead times for large parts, prototypes and tooling.

Based on the company’s patented Gel Dispensing Printing (GDP) technology, which instantly cures parts during the printing process and minimises the need for support structures, Massivit says the printer promises “new resolutions, materials and automation capabilities” and has the potential to deliver production speeds up to 30 times that of existing technologies for the manufacture of large-scale industrial parts.

The Massivit 5000 launches alongside a new printing material, DIMENGEL 110, which is said to deliver high-definition printing and greater conformity to CAD designs. The machine offers two new resolutions which allow users to optimise print resolution according to layer thickness and speed requirements, and it is also equipped with a Dual Material System that enables simultaneous printing with two different material. Meanwhile, a new software automation feature has been introduced to allow operators to improve workflow efficiencies and enable easy monitoring and operations.

Erez Zimerman, CEO at Massivit 3D, said: “We are thrilled to bring to market this new additive manufacturing system that will empower manufacturers to overcome existing limitations in production speed, size, and complexity. It is a significant milestone on our roadmap towards transforming manufacturing of large parts across multiple industries.”