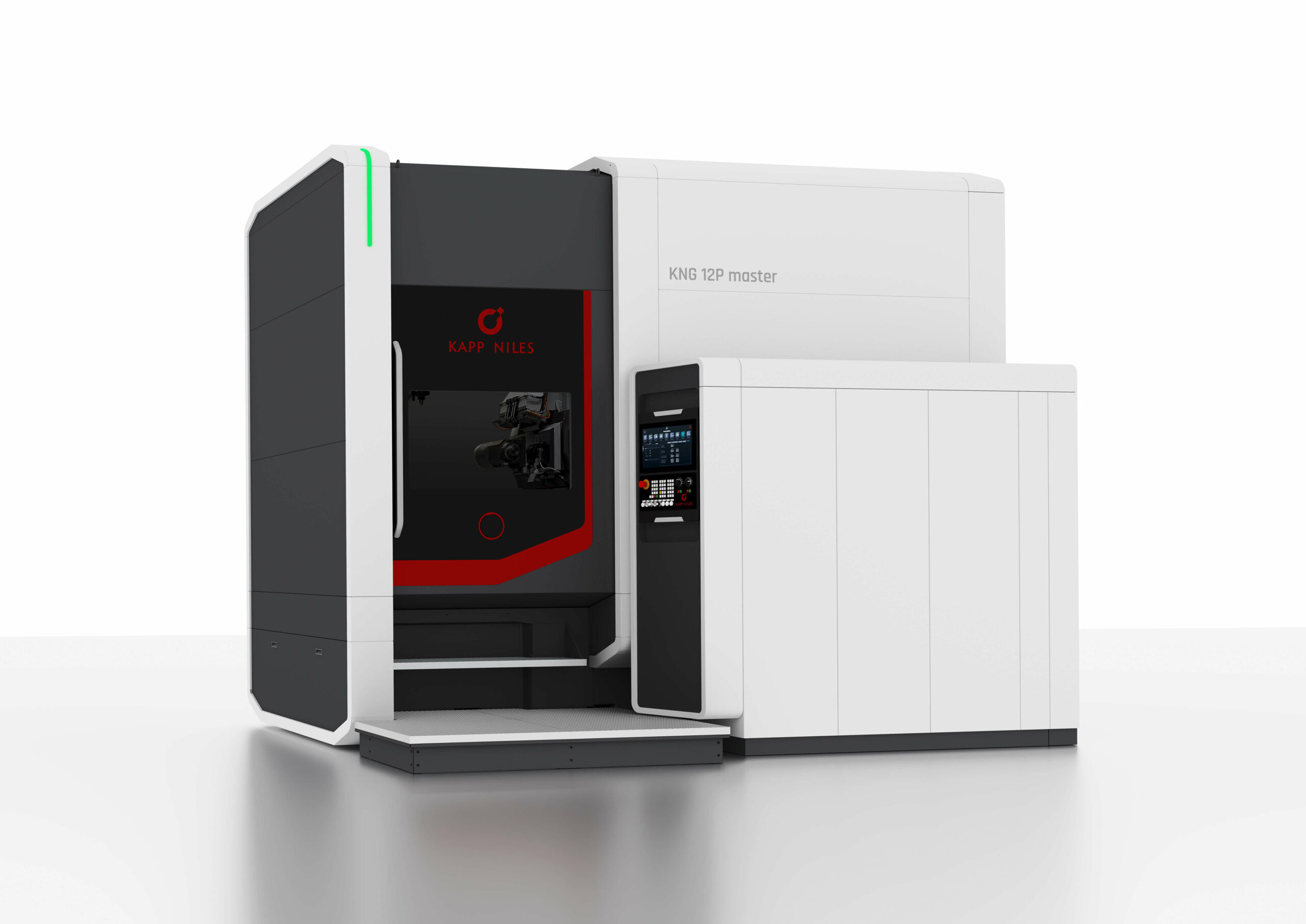

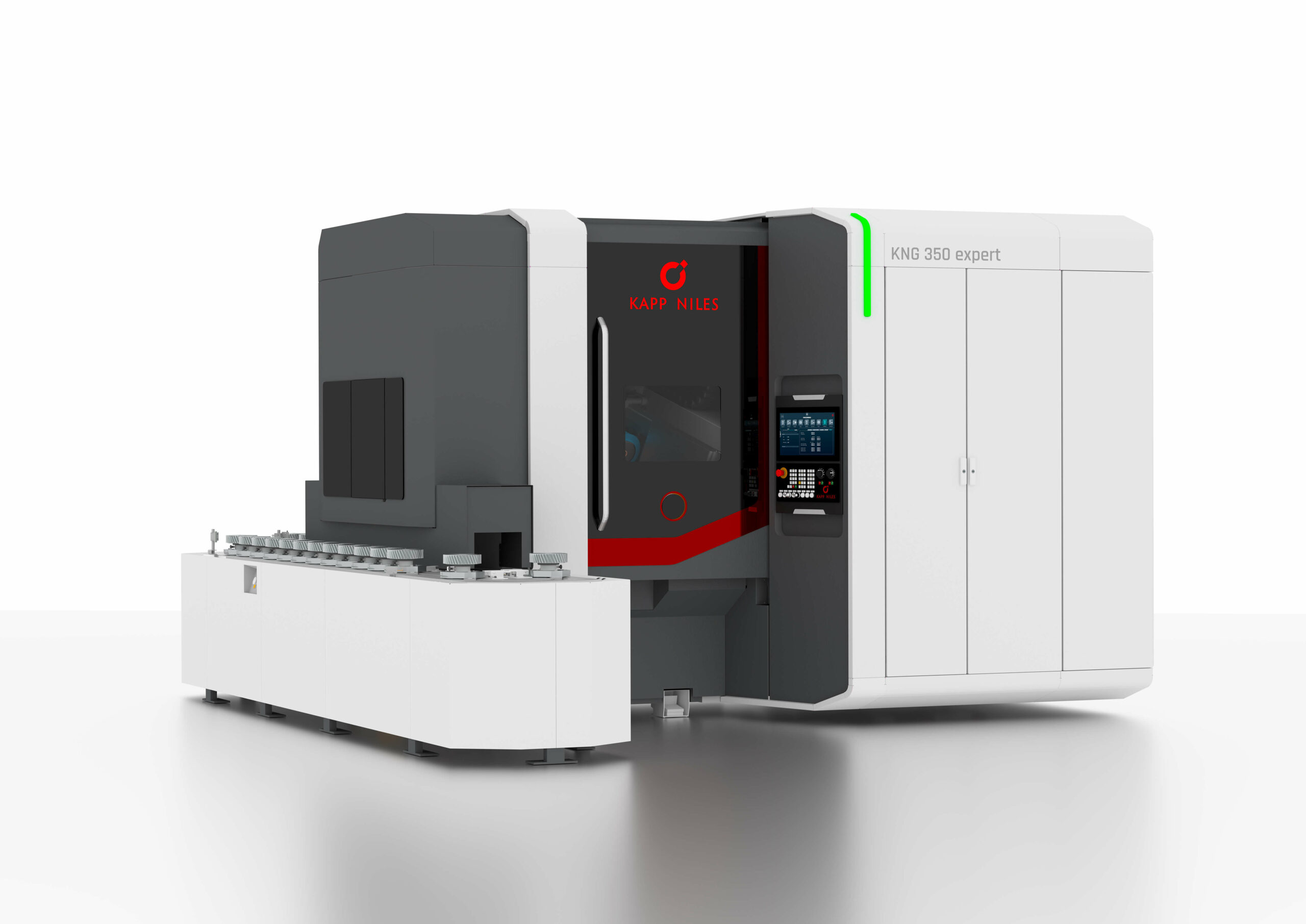

Short profile KAPP NILES group

KAPP NILES is a globally operating group of companies with high-quality and economical solutions for finishing gears and profiles. More than 800 employees represent the innovative strength and expertise of the sustainably managed family company which has grown for over 120 years.

With production sites in Germany as well as worldwide sales and service branches, we are responsive and reliable in all major markets.

KAPP NILES is partner for companies from numerous industrial sectors in our segments mobility, automation and energy.

The perfect interaction between machines, tools, and technologies enables the precise machining to a thousandth millimetre and up to a diameter of eight metres.

Each system solution is individually optimised for customer requirements and serviced by us throughout its life cycle. Highly accurate measuring equipment complements the comprehensive product range to ensure the required quality.

KAPP NILES supports efficient and stable processes with innovative services and digital solutions.

Products:

- Machine tools for the finishing of gears and profiles for the following processable workpieces

- gears and shafts with outer straight and inside straight helical gears

- gear related profiles

- compressor rotors

- ball screw tracks

- worms

- rotary pistons

- pump spindles

- gerotors

- vane pump rotors

- Non-dressable grinding tools with CBN- and diamond covering

- Dressable tools with or without tip dresser for workpiece related or flexible dressing

- Measuring machines and instruments

- Services

- Digital solutions

Industrial sectors:

- Mobility

- Automation

- Energy

Hard finishing machining processes:

- Generating grinding

- Profile grinding

- Bore and end face grinding in combination with gear processing

Digital solutions

RFID technology

As well as constant optimisation of machining times, the reduction of set-up and non-productive periods also always play an important role in a flexible production environment. In addition to machine concepts with optimised set-up times, KAPP NILES offers intelligent components.

For set-up processes the technological data of components and tools is made available to the controller by using RFID technology, which enable an identification without any contact between antennas and RFID chips in the machine. In order to correctly identify the components, the operator is guided through intuitive step by step menu navigation, thus reducing the possibility for faulty inputs.

All necessary geometric and process-related data, which unambiguously describes the respective component, is carried along on the data carrier and is updated during installation or removal.

The key advantages of RFID technology are that it prevents incorrect component installation, it automatically reads and transfers component data, it prevents incorrect entries, which results in shortening of the overall input time, as well as preventing downtimes due to incorrect component installation.

The machines are designed to also handle non-RFID components. Maximum flexibility for customer requirements is guaranteed.