DMG MORI, a leading machine tool manufacturer, has expanded its additive manufacturing portfolio with the launch of its new Lasertec 30 Dual SLM system.

Equipped with two 600 W (optionally 1 kW) lasers in the optics module, the new machine is capable of building either one component or several parts at once, therefore providing the user with flexibility to meet different order situations. It is an upgrade on the standard Lasertec 30, which features a single laser.

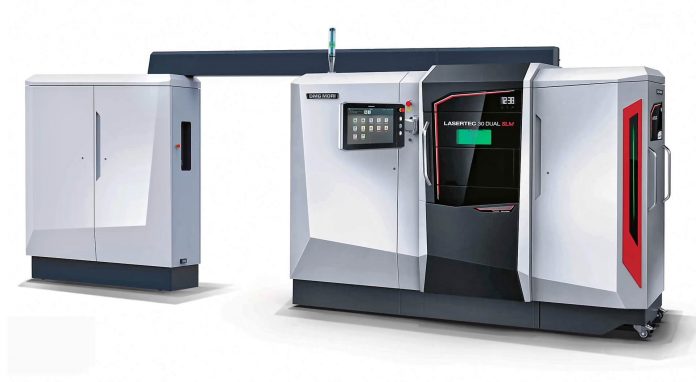

The Lasertec 30 Dual SLM system

Central to DMG MORI’s new SLM system is its dual laser technology. The scan field of each laser on the Lasertec 30 Dual SLM covers the entire build chamber, which measures up to 300 x 300 x 300 mm. This enables build rates of up to 90 cm³/h, and raises the output of the machine by 80 percent compared to a machine equipped with a single laser.

Productivity is further enhanced by an active cooling system for the build area which allows users to remove finished components and prepare orders faster. The laser spots’ focus diameter can be adjusted from 300 microns down to 50 microns, therefore providing high accuracy melting capabilities.

Additionally, the Lasertec 30 Dual SLM comes equipped with Optomet software for parameter optimization, and Celos software for CAM programming and machine control. The Optomet software automatically identifies the scan strategy that is most efficient for the print job at hand, thus optimizing its performance.

Optomet also includes tools for optimising power and exposure strategies in order to improve machine performance, as well as for controlling the temperature throughout the build volume. This allows users to normalise conditions of the Lasertec 30 Dual SLM and reduce residual stresses in the parts being 3D printed.

Celos on the other hand provides touchscreen-based machine operation, CAM programming directly on the machine control, and an array of monitoring tools including camera-based process monitoring of the build-up and coating quality.

Another feature is DMG MORI’s rePLUG module for material change and powder supply. It enables automated powder handling and powder-recycling to increase production efficiency. The module also allows users to change materials without contamination in less than two hours, according to DMG MORI. The Lasertec 30 Dual’s material compatibility ranges from tool steel and stainless steel through aluminium and cobalt-chrome to Inconel and titanium, therefore providing options for a number of industries.

Technical specifications:

|

Technology |

SLM |

|

Build volume |

300 x 300 x 300 mm |

|

Min. Layer thickness |

20 µm |

|

Max. Layer thickness |

100 µm |

|

Min. Focus diameter |

50 µm |

|

Max. Focus diameter |

300 µm |

|

Laser power standard |

600 W |

|

Laser power optional |

1,000 W |

|

Inert gas |

Argon |

|

Software |

Optomet and Celos |