As assembly of ITER begins, scientists and engineers are already looking ahead to the technologies that will take fusion power a step closer to the grid. Stuart Nathan reports

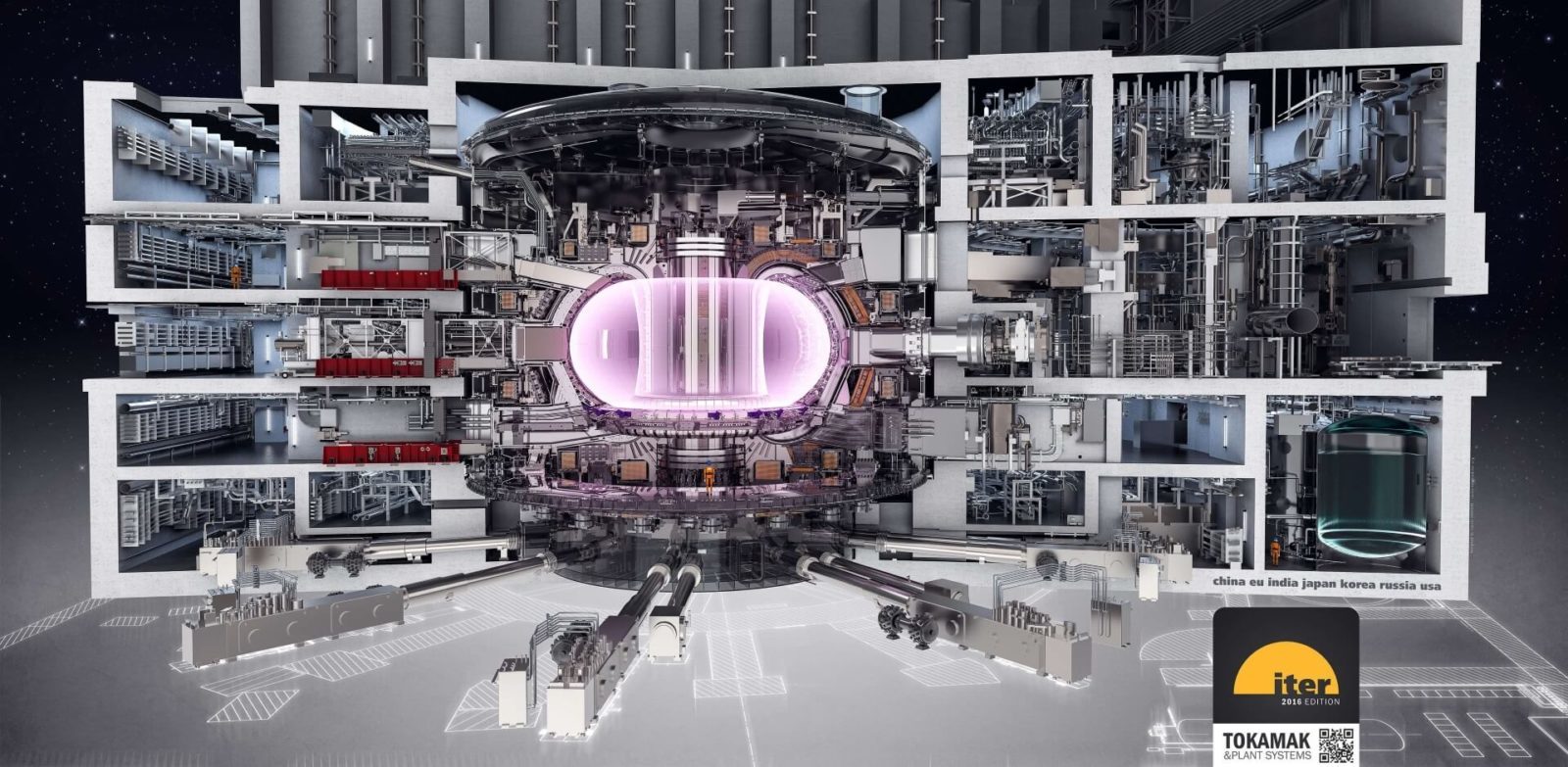

Nuclear fusion took an important step forward last month with the beginning of the assembly phase of the experimental fusion reactor ITER at Cadarache, near Marseille. It was a humble start for a momentous event: the first completed component was transferred into the fusion machine’s ultimate location. Over the next five years, increasingly complex parts will make the journey inside the concrete walls that will enclose what is planned to be the first reactor to achieve self-sustaining fusion – what’s known as a “burning plasma”. At this point, however, many of the components have not yet been completed.

Despite this, planning and even engineering studies have already begun on ITER’s successor. This will be called DEMO, and while ITER will sustain a burning plasma, DEMO is planned to be the first real nuclear fusion power station, expected to supply electricity to a grid.

The ITER project, involving a total of 35 nations (The European Union plus Switzerland, along with the US, China, India, Japan, Russia and South Korea) is projected to take 25 years to complete once its reactor is built, and DEMO cannot start until it is finished. ITER will generate no electricity, but will investigate how to best operate a fusion reactor large enough to sustain a burning plasma – size has been one of the biggest stumbling blocks to achieving this.

So it might seem strange that engineering has begun on a project decades into the future. However, this does not look so odd if fusion is regarded as a single mega-project rather than a series of smaller projects (even though ITER is a mega-project in its own right).

It then seems only logical that potential future problems should be addressed when they become apparent, rather than when they block progress. This means that engineers today are working on projects which might be completed only after they retire or even after they die. We don’t think it peculiar that mega-projects of the past – say, medieval cathedrals – spanned several lifetimes.

On the current schedule, according to the fusion roadmap published by Fusion4Europe (F4E) – the organisation which manages the European Union’s contribution to nuclear fusion research and is de facto manager of ITER – the reactor is scheduled to begin its first experiments in 2025 and complete them around 2045. Construction work on DEMO could conceivably begin before 2045, and there might be some small overlap in operation, but the roadmap envisages electricity production from DEMO by 2050 and the pace of work between 2045 and 2050 can be expected to be frenetic.

DEMO and ITER will be quite different machines, but both belong to the same general category of fusion reactor. Known as tokamaks (a Russian acronym for toroidal chamber with magnetic coils) these perform fusion in a heated plasma – a gas made up of charged particles – formed from different types of hydrogen atom.

Fusion is the process by which all stars generate energy, and they use the most abundant and simplest type of hydrogen as fuel – a single proton associated with a single electron. However, stars have enormous mass, and the colossal gravitational forces in their interior crush hydrogen to a density much greater than steel (a cubic centimetre at the centre of the sun has a mass of 160g. A cubic centimetre of steel has a mass of about 8g). Stellar fusion is a complex multistage process whereby multiple protons have to collide and fuse together, emitting other particles, to eventually form a helium nucleus of two protons and two neutrons, but the density and temperature are so great that this sequence of events is likely.

In a tokamak, gravitational crushing is replaced by magnetic fields which squeeze the plasma and different techniques are used to heat it, accelerating the particles so they overcome their electrostatic repulsion (only nuclei are fused and they all have the same positive charge) but even so, the density of the plasma is so low that the type of sequence of particle collisions that occurs in stars is hugely unlikely. To simplify the process so that only two particles need to collide in a single step, tokamaks use as fuel a mixture of deuterium (hydrogen with one proton and one neutron in the nucleus) and tritium (one proton and two neutrons).

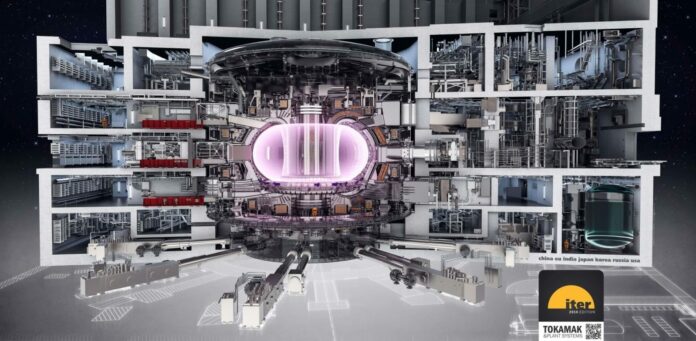

As the Russian name implies, tokamaks are toroidal – shaped like a ring doughnut (ITER is a slightly distorted doughnut: the central hole is cylindrical, so the cross-section is D-shaped rather than circular).

The toroidal reaction chamber has three sets of magnets to provide the huge magnetic fields needed to confine hot plasma: a single large solenoid running down the middle, circular magnets surrounding the outer circumference (known as the poloidal field or PF coils), and D-shaped magnets that run up the inner wall of the central hole and down the outer wall (known as toroidal field or TF coils). These are all made from a superconducting material that needs to be cooled to a few Kelvin above absolute zero so they conduct electricity with no resistance and do not reduce the overall power demand of the system. Development of such materials was another factor that has delayed successful production of more power from a fusion reactor than it took to maintain the fusion reaction – that is, to power the magnets and heat the plasma.

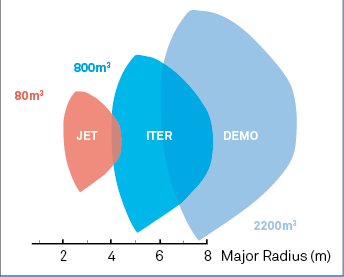

Both DEMO and ITER will have these essential components – toroidal vacuum chamber, central solenoid and PF and TF coils – as well as heating systems to accelerate the plasma particles, but that is the limit of their similarity. The most obvious apparent difference will be size. Although ITER is by some margin the largest tokamak ever built, DEMO will be even larger. According to Tony Donné, programme nature for EUROfusion, the European consortium for development of fusion energy and part of F4E, its linear dimensions will be some 15 per cent larger, giving its vacuum chamber a volume of 2200m³ compared with ITER’s 800m³.

The research on sizing DEMO represents the first stage of engineering design on the project, and Donné has led these studies at Eindhoven University of Technology. The larger size will ensure that DEMO produces enough “excess” energy to be useful for generating electricity, Donné explained.

“ITER is intended to produce about 10 times as much energy as it takes to maintain fusion,” he said. “We call the ratio of ‘power out’ to ‘power in’ the Q factor, and at the moment no fusion reactor has exceeded a Q factor of one (Q1). ITER’s performance we call Q10, but because of the inefficiencies inherent in generating electricity – with heat exchange and turbines – Q10 is nowhere near enough to be useful. We need DEMO to produce about Q25, somewhere around 2 to 4GW of thermal output. Possibly full-scale commercial fusion stations will need to produce an even higher Q factor, maybe Q100.”

This sounds enormous when no one has achieved Q1 yet, but the potential energy content of fusion fuel is huge. The relevant equation, of course, is E =mc2, where m, the mass being converted to energy, is the minute difference between the mass of a helium nucleus and the sum of the masses of a deuterium and tritium nucleus minus the single neutron emitted in the reaction, but c2, the constant factor by which the mass is multiplied, is such an enormous number – almost 10 raised to the 17th power – that an enormous amount of energy is theoretically available for every gram of deuterium-tritium mixture.

“The extra energy output dictates the larger size, and also means that we need a plasma about 30 per cent more dense. This means there is more fuel, and therefore more fusion events, and therefore more energy produced,” Donné added.

Donné’s mention of heat exchange demonstrates another difference between ITER and DEMO. Unlike nuclear fission reactors, fusion reactors do not rely on cooling for safe operation. However, to generate electricity, the heat produced by fusion needs to be extracted and used to boil water to drive turbines. ITER will have only experimental small cooling systems to investigate the best ways to operate them, but DEMO will need a full-scale cooling system covering the entire inside surface of the vacuum vessel. This will form the power station’s primary coolant circuit, which will be connected to steam generating systems via heat exchangers in a secondary circuit.

The vacuum vessel lining is known as a blanket, and in DEMO will have a dual purpose. As well as extracting heat, it will also have to generate tritium, and the two functions are likely to be combined. Tritium barely exists in nature; only being formed by interactions of matter with energetic cosmic rays. It currently has a few commercial uses – in making luminous markings, labelling chemicals in research to analyse reaction dynamics, tracing processes that occur in the oceans and making nuclear weapons, so it is manufactured in small quantities inside certain specialised types of nuclear fission reactor. It is toxic and radioactive. Currently, the only fusion reactor which is even capable of using tritium is the Joint European Torus (JET) at Culham in Oxfordshire, which will be the largest tokamak in the world until ITER’s completion.

Nuclear fusion in ITER will require relatively large amounts of tritium, which will be imported from the current sources and handled in a dedicated plant. However, DEMO will need commensurately larger volumes, and it will not be practical to make it using current technology. Instead, the blanket will make tritium in situ by exposing lithium to bombardment by the high-energy neutrons produced by the fusion reaction. The tritium will then be extracted from the lithium and purified.

Once again, this technology will be trialled in ITER. The blanket in the Cadarache reactor will be essentially non-functional, serving primarily as armour to protect the steel walls of the vacuum vessel. However, modules will be emplaced in the armour blanket incorporating four prospective lithium-to-tritium breeder mechanisms. The most successful of these will be used in the blanket modules that will line the entire DEMO torus.

JET, as mentioned above, is an important testbed for technologies that will be used in both ITER and DEMO, but it is not the only one. Most of the plasma devices around the world – whether or not they are capable of actual fusion – are part of the research effort. Only a few miles from ITER, another tokamak, currently known as WEST but previously called Tore-Supra, has already carried out valuable research into the use of superconducting magnets in fusion, and has more recently been testing an important component called the diverter. In the base of the reaction vessel, this is the only part of it that comes into direct contact with the fusion plasma.

In the early years of tokamak research, the entire lining, including the diverter, was generally made from graphite panels that can withstand high temperature. However, because of the tendency for the carbon in graphite to react with hydrogen and the potential hazards posed by resulting tritium-containing hydrocarbons, the diverter at Tore-Supra was replaced by a tungsten component. JET now has a tungsten diverter to go with its beryllium-covered inner surface, and ITER will also use beryllium and tungsten. The expectation is that DEMO is likely to follow suit.

The diverter is now the focus of probably the most intense DEMO-directed engineering research. “As we start to put high-energy loads into tokamaks like JET, we are beginning to see the sort of problems that we might encounter with the diverter,” explained James Harrison, a researcher at Culham working on another of the centre’s experimental tokamaks, Mega-Amp Spherical Tokamak (MAST), which is currently being upgraded for a new phase of research.

“There are two sets of issues that we know we will face: the first is the wear on the tungsten ‘target panels’ where the particles in the plasma impinge directly and expend their considerable energy; the second is how we extract the heat from the plasma in that region, which will provide a large proportion of the total heat that we extract from the vacuum chamber. In the first case, we want to avoid having to replace diverter panels too frequently. In the second, we want to extract the heat as efficiently as we can to transfer it to the secondary cooling circuit where it can be used to generate electricity.”

For more on the various diverter research projects, see the box on page 30.

Harrison touches on one of the most important factors in the engineering planning for DEMO. ITER is proving to be a hugely costly project, although a major factor in the cost overruns has been the rise in the price of steel. The ITER tokamak is mainly composed of high-grade stainless steel, and there is even more steel in the reinforcements to the concrete buildings containing the fusion machine. But part of the rationale behind the whole fusion mega-project is to ensure that eventually, fusion energy is available to any country that wants it; and that means that methods must be found to reduce the cost. One factor works in DEMO’s favour: although it may seem paradoxical, it will be less complex than ITER, which will have complex control systems to generate different plasma shapes and many sensors and diagnostic devices. DEMO, by contrast, will be designed and operated only to generate the largest possible amount of electricity. Its controls and sensors will therefore be optimised to enable that.

“It’s also inevitable that we will learn a great deal from building ITER, and all that learning will help us to identify ways we can reduce costs in building the successor machine,” Donné said.

Another seemingly paradoxical possible money-saving factor is that DEMO might not be such a multinational project as ITER. One of the peculiarities of the Cadarache project is that all 35 nations involved are contributing either components or expertise, and this means that manufacturing is taking place at a very large number of facilities, all of which have been specially built. The logistics of transporting these components also carries a very high cost. If, for example, only Europe was involved in DEMO, many of these costs could be eliminated, explained Donné. Moreover, he added, this could be a major factor in reducing the costs of further fusion reactors.

“We would already have the necessary production facilities and tooling and would not have to build new ones every time,” he explained. “What’s more, although building a fusion reactor is always going to be expensive, running it will not be. The fuel components – deuterium and lithium – are so abundant that, compared with the building cost, they are virtually free.”

The design of DEMO is not yet fixed. At the moment, Donné said, it is assumed that it will have similar geometry – if different proportions – to ITER, as these will have received the most study. However, other tokamak geometries are under investigation around the world, and it is not inconceivable that one of these might be chosen. Spherical tokamaks such as MAST at Culham, for example, have some advantages related to plasma stability, and have a slightly different shape.

Culinary comparisons remain useful: if ITER is a ring doughnut, spherical tokamaks are cored apples. A prospective design is expected to be chosen for DEMO around 2020.