Transforming the Future of Manufacturing Through 3D Printing Innovation: Optimized Production (3DoP)

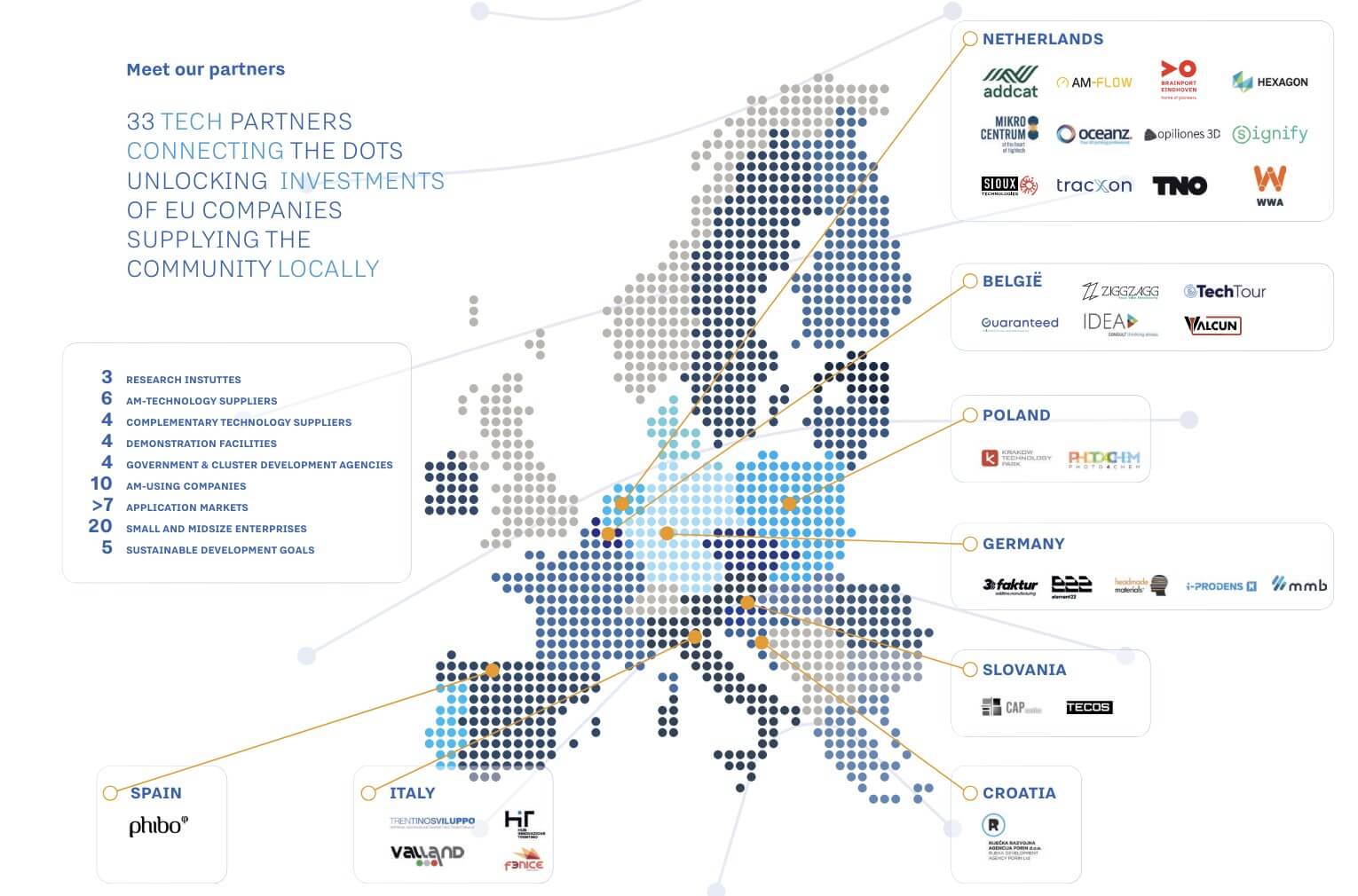

Project Partners

In total, 33 partners are involved in this EU project. These range from research institutes and government agencies to small and medium enterprises from many EU member states.

The most notable partner is Signify, the world leader in lighting for professionals, consumers, and lighting for the Internet of Things, formerly known as Philips Lighting.

Other companies worth mentioning are Tracxon from the Netherlands, ValCUN from Belgium, and 3Faktur from Germany.

Tracxon transforms Hybrid Printed Electronics from a niche technology to a mainstream cradle-to-cradle manufacturing technology through continuous process and product innovation.

ValCUN is a dynamic tech start-up that develops a new and disruptive metal 3D printing technology: Molten Metal Deposition. They aim for fast and affordable metal 3D printing, enabling mass production.

3Faktur is a 3D printing service provider for additive series production of high-quality industrial plastic parts as prototypes or in batch production.

Project Goals

The 3DoP project aims to deliver new or improved products, processes, and services in the manufacturing industry.

This includes enabling efficiency and sustainability in 3D metal printing. It also reduces costs and time through innovative applications like 3D printed moulds with imprinted electronics. The project fosters automation in the dental industry and 3D Print factories for Industry 4.0. Specific work packages include:

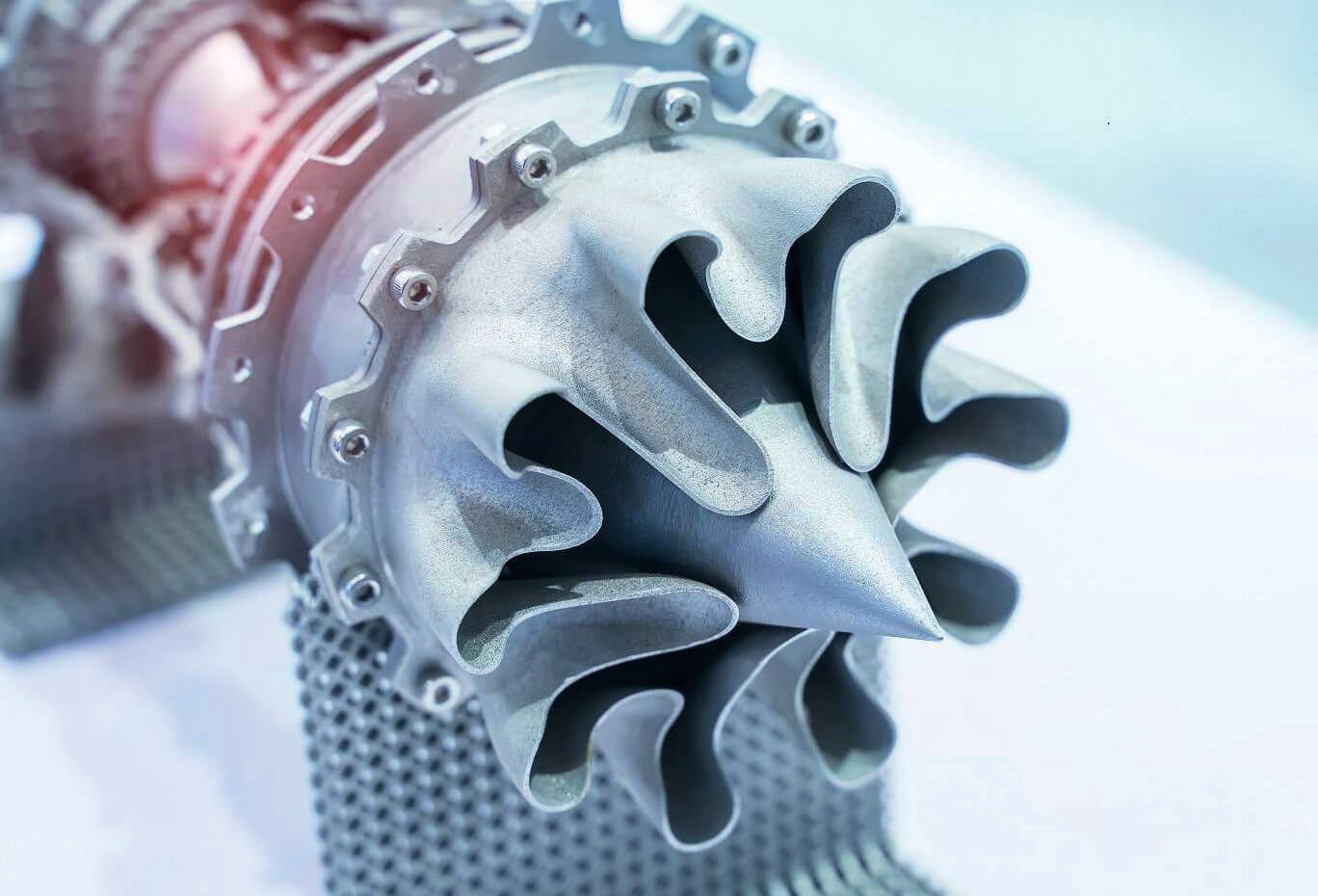

- Work Package 2: Focuses on making 3D metal printing more affordable and accessible to reshape the landscape of 3D metal printing.

- Work Package 3: Explores the potential of 3D printing in toolmaking and mould-making. It introduces imprinted electronics for enhanced functionality.

- Work Package 4: Targets the dental industry. It addresses challenges in dental prosthesis manufacturing through automation. Creating an automated production line for 3D-printed dental implants and aligners aims to boost productivity, reduce waste, and enhance overall efficiency.

- Work Package 5: Tackles the challenge of automating 3D print factories. It recognizes the complexities involved in post-printing processes. These solutions extend beyond 3D printing and potentially influence industries such as healthcare and aerospace.

- Work Package 6: Plays a crucial role in unlocking further opportunities and ensuring long-term sustainability by attracting investments.

Rijeka Development Agency Porin’s Involvement

Rijeka Development Agency Porin’s Involvement

Rijeka Development Agency Porin is involved in Work Package 3 and Work Package 6.

Porin’s role in Work Package 3 is to provide 3D-printed metal moulds for injection moulding of plastic parts with integrated electronics.

Porin’s metal 3D printing capabilities are ideal for this application. We can produce moulds with internal cooling channels needed to quickly cool injection moulded plastic parts.

This reduces the duration of the production cycle and prevents the warping of plastic parts by providing an even temperature.

In addition to metal 3D printing, we also offer 3D printing of large polymer parts from engineering materials (PEEK, Nylon, ASA, etc.).

We provide 3D printing casting moulds from sand and binder, 3D scanning, reverse engineering, and product development.

Contact Us

If you would like to discover how the Torpedo Manufacturing Park and the Rijeka Development Agency Porin can enhance your business, please contact us

via email at pptorpedo@porin.hr or rraporin@porin.hr,

or by phone at +385 51 634 331.