New design for direct-drive motors for machine tools, with very low cogging torque – almost half the current standard

CNC developer NUM has expanded its portfolio of motors for machine tool applications by launching a range of high-performance brushless torque motors. Employing innovative, optimized magnetics, NUM’s new TMX series direct-drive motors have an extremely low cogging torque – almost half that of competitors’ motors. They are said to be “ideal for applications that demand very smooth and accurate rotation, especially at low speeds.”

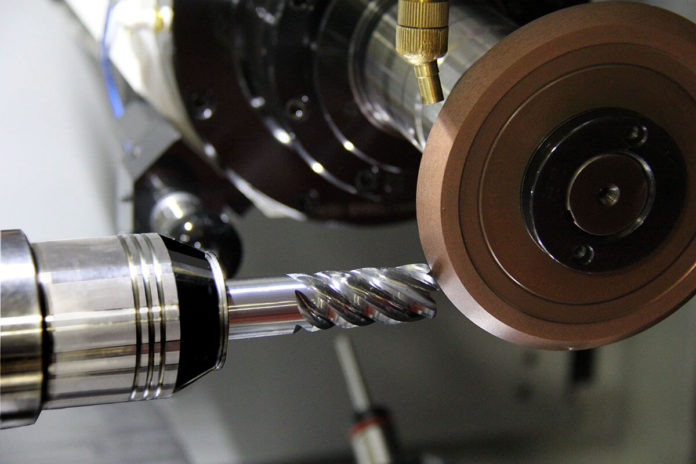

Typical uses include direct-drive machine tools, rotary tables and radial positioning units.

In addition to developing CNC technology, NUM is known for high-quality, reliable motors, and has been developing specialized motors for automation, especially for machine tools. It pioneered the development of AC brushless servo motors and has produced more than 5,000 different types; its current range covers torques from 0.318 to 160 Nm and speeds up to 8,000 rpm.

NUM also manufactures a range of synchronous and asynchronous motor spindles with flux weakening, offering power outputs as high as 55 kW.

For direct-drive applications, NUM has generally specified torque motors produced by IDAM (Drives & Mechatronics AG & Co. KG), which specializes in direct-drive technology.

However, as Massimiliano Menegotto, general manager of NUM’s main manufacturing plant in Milan, Italy, explained: “A growing number of our customers request customized motors, and prefer to deal with a single supplier for all their CNC machine tool requirements.

“We have developed the TMX series of torque motors specifically to address these needs,” Menegotto continued. “They complement those produced by IDAM and provide us with additional in-house configuration flexibility, enabling us to offer customers an even wider range of solutions.”

TMX series frameless torque motors

Source: num.com

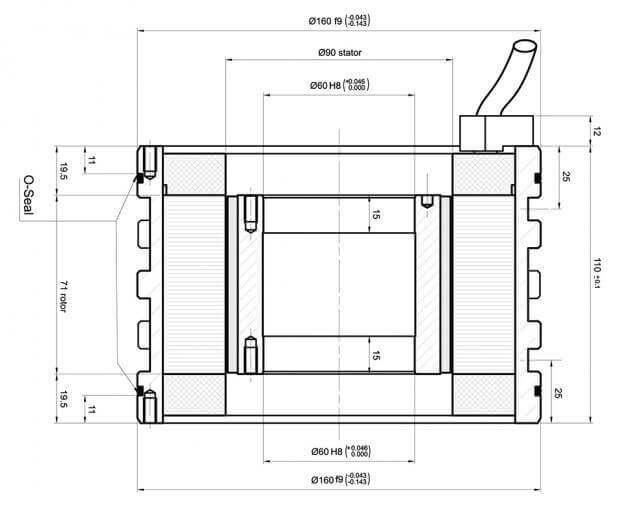

Last year NUM launched two TMX series frameless torque motors, with stator diameters of 140 mm and 291 mm, and intends to expand the range in the future. The motors’ hollow shaft rotors use high flux density neodymium-iron-boron (NdFeB) magnets and offer ample internal space for through-motor wiring or mechanical parts.

Source: num.com

The stator windings are fully protected against over-temperature conditions and are encapsulated within a thermally optimized enclosure that offers a choice of air-cooled and water-cooled configurations.

Like all direct-drive motors, the TMX series units are able to deliver continuous torque even when stalled, and are designed for direct attachment to the load. This avoids the need for gearboxes or shaft couplings to provide highly accurate, backlash-free rotary transmission. The rotor and frameless stator are supplied as component parts and are primarily intended for applications that require total integration of the motor within the servomechanism in order to reduce weight or volume.

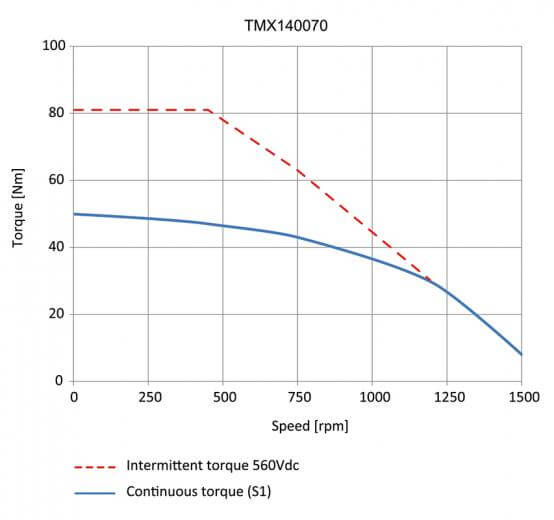

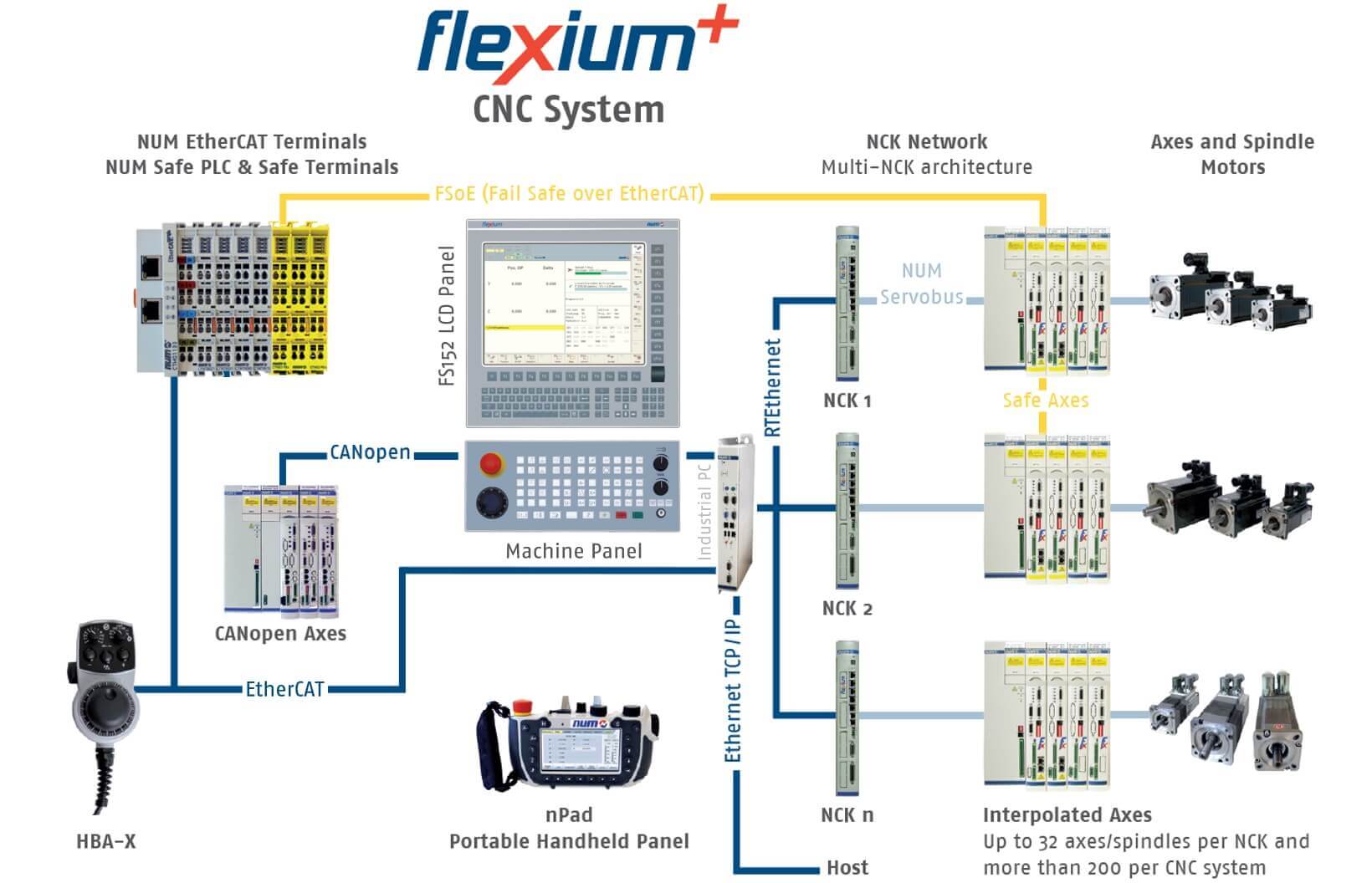

NUM’s TMX series motors can produce a very high S1 torque density and are available with a choice of stator and rotor lengths to best suit the motion requirements of the application. For example, a 140-mm diameter motor with an active length of 70 mm can produce a peak torque of approximately 82 Nm at speeds up to 1,500 rpm, and a continuous (stall) torque of approximately 50 Nm. The motors can be driven by most industry-standard servo drives, including NUM’s MDLU3 and MDLUX drives, which form part of the company’s latest-generation Flexium+ CNC platform.

Source: num.com