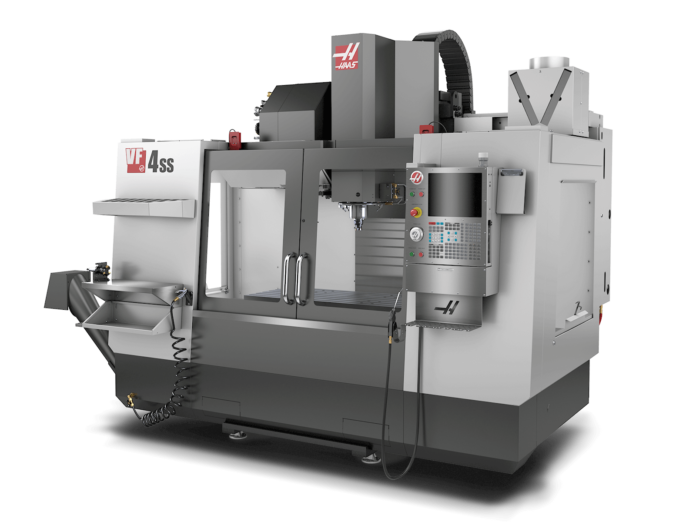

Haas CNC machine tool product data is now available on MachiningCloud. The files are in GDML format and contain simplified 3D models of the machine tool along with the machine’s kinematics making them ready for use in your CAM and simulation software. For this initial release, GDML product data is available for the following machines: VF-2, VF-2SS, VF-3, VF-3SS, VF-4, VF-4SS, VF-5/40, VF-5SS, VF-6/40, VF-6SS, VF-7/40, UMC-750, UMC-750SS, Mini Mill, Super Mini Mill, Mini Mill 2, Super Mini Mill 2, Mini Mill-EDU, VM-2, VM-6, EC-400, ST-20Y, DS-30Y.

The Haas MachiningCloud partnership utilizes the convenience and reach of MachiningCloud’s technology and enable customers to easily gather the product data they need to drive their CAM, Simulation and other data-hungry shop software. MachiningCloud simplifies the way customers gather the 3D CAD Models for their Haas CNC machines, workholding and cutting tools by providing them in one place and in the formats needed for today’s shop software. Included with the product data of more than 750,000 cutting tools, beyond the 3D CAD models, MachiningCloud also provides the descriptive information needed for part programming, and the usage information, including speeds and feeds, needed to run the selected cutting tools on the customer’s Haas machines.

While Haas Automation designs and manufactures CNC machine tools for the metalworking industry, MachiningCloud is a product data provider for world-leading cutting tool, CNC machine tool, workholding, and metrology manufacturers.

“By publishing their product data on MachiningCloud, Haas Automation is showing an industry-leading commitment to supporting their customers’ need for easy access to the information needed to drive their shop software. By having the product data for their machines, cutting tools and workholding available in one place, customers can quickly and easily find what they need to program their jobs and keep the chips flying”, says Christophe Rogazy, Director of Product Management for MachiningCloud.

“Haas Automation offers 3D CAD models for their complete line of CNC machines, allowing our customers to easily program and simulate their manufacturing processes offline in their shop software. By providing the models on MachiningCloud, we are providing our customers a convenient, single-source for the machine and cutting tool product data they need to run their shop”, says Scott Gasich, VP of Sales and Marketing at Haas Automation.