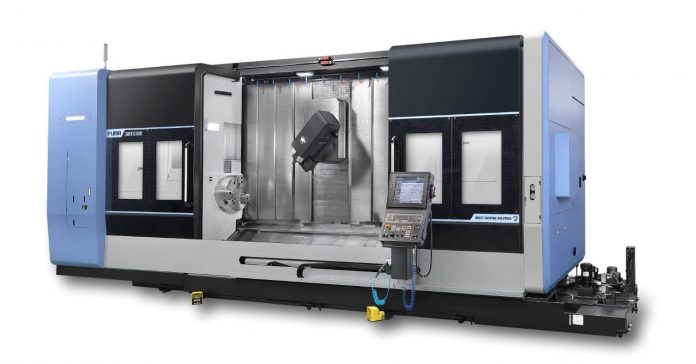

Doosan Machine Tools’ Puma SMX5100L twin-spindle, multitasking turn-mill, is the largest machine in the Puma SMX series, with a maximum turning diameter of 32.7″ and maximum length of 120.1″.

Chuck sizes of 15″, 18″ and 21″ are available for the standard main turning spindle, which features a built-in, 49.6-hp motor that spins at 2,400 rpm. Also available is an optional gearbox spindle that rotates at 1,500 rpm and outputs 4,198 Nm of torque for heavy-duty applications. The machine is ideal for aerospace applications such as landing gear components or housings for large shafts like those found in agriculture or oilfield industries, the company says.

The B-axis milling head features a Capto C8 spindle powered by a 49.6-hp motor that rotates at 10,000 rpm. The roller gear cam mechanism that drives the B axis is backlash-free and highly rigid, outputting B-axis torque of 2,700 Nm.

The machine’s rigid construction minimizes thermal deformation via sensors placed throughout. The sensors offer real-time measurement and adjustment of the axes. For added stability and speed, the Z axis is supported by three rows of cross roller linear guideways.

FANUC five-axis machining software is built into the SMX-series control. The software provides 600 blocks of look ahead and optimized servo acceleration/deceleration.