Chiron’s Series 22 machining centers come in both four- and five-axis varieties, with modular solutions for a wide variety of high-precision tasks.

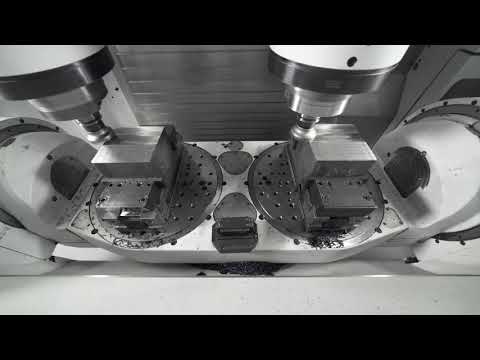

Chiron’s new twin-spindle five-axis series DZ 22, with a 600 mm spindle clearance, is designed to completely and rapidly machine complex, large workpieces like housings for electric motors and transmissions, oil pumps and chassis components. The company also offers a four-axis variant of the Series 22.

Chiron attributes the Series 22’s success to the moving gantry design. The rigid machine bed and active component cooling enable the required degree of precision on the workpiece, while high acceleration – 10 x 10 x 17 m/s² – and rapid response to programming inputs ensure dynamic machining. Axis travel distances are 620 x 650 x 600 mm and rapid traverse speeds are up to 120 x 120 x 90 m/min.

The Series 22’s magazines hold up to 77 tools, and the integrated workpiece changer saves cycle time by loading and unloading the workpieces during machining, with a 3.1 second chip-to-chip tool change time. A fast main spindle features a 20,000 rpm speed and a 137 Nm torque, while a strong spindle features a speed of 12,500 rpm and a 200 Nm torque. The Series 22 is also available as an HSK-A100 machine for further stability and performance.

The Series 22 is available with a ball screw drive or a linear direct drive, as well as a suspension plate for four-axis machining or two face plates for five-axis simultaneous machining. All models are compatible with a cooling system, suction unit, chip conveyor and other individual tool packages.

Various SmartLine modules optimize the Series 22’s productivity, product quality and machine availability. ConditionLine detects non-typical operating behavior and helps plan maintenance and repair, while ProcessLine and ProtectLine use a digital twin to safeguard against machine crashes and the TouchLine operating system simplifies operation.