Starrag supplies a Droop+Rein 5-axis gantry machine with an 11-metre rotary table to the other side of the world.

The Australian Government (Commonwealth of Australia) selected French company Naval Group to deliver a fleet of 12 regionally superior submarines, to be known as the Attack Class, for the Royal Australian Navy. The Attack class fleet will be built in a modern submarine construction yard in Osborne, South Australia.

The Future Submarine Program will deliver Australia a capability that can be built, operated and maintained with sovereignty, which maximises opportunities for Australian industry throughout all phases of the program.

As the design of the Attack class progresses, Naval Group continues to deliver on its commitment to achieve this through their suppliers, a pool that now includes the Starrag Group. Dr Marcus Queins, Manager for the Large Parts Machining Systems business unit, explains: “We are proud to be involved in this prestigious project in Australia.”

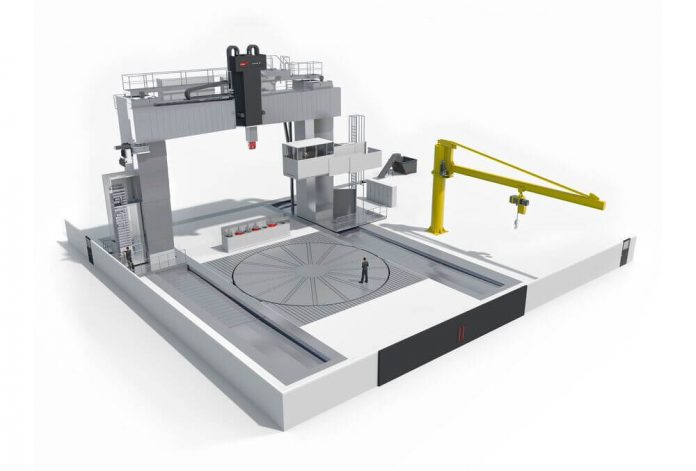

Starrag has been selected to supply a Droop+Rein G 110TT HR100 C vertical gantry machine, capable of handling both large hull elements and high-precision components for submarine construction. With traversing paths of 14,000 x 13,000 x 3,500 mm in the X/Y/Z axes and an 11 m turntable, the gantry will be the largest machine tool ever put into service in Australia.

Starrag is collaborating with the Australian machine tool manufacturer H&H Machine Tools Australia to deliver this important equipment. The company will manufacture key components, supply qualified personnel to help install the gantry and provide technical support for the entire life cycle of the machine, securing an enduring role in servicing and maintenance in the future. Starrag will provide H&H with the necessary expertise through on-site training and quality control, transferring critical skills and sovereign ability to Australian industry.

The contract was awarded following a complex selection process. Noting its many years of experience and its extensive, not merely technical, expertise in handling large, complicated projects, the Starrag Group was an obvious selection for this contract. Not every machine supplier can manage an order of this magnitude from over 15,000 kilometres away — but this is no problem for the Starrag Group, as Australian sales partner H&H Machine Tool Solutions will facilitate local work, ensuring that everything runs smoothly on-site. A previous project carried out in South Australia, for which Starrag supplied four machines for aircraft construction, shows a proven track record in this regard.

Gantry machine for precise heavy-duty cutting of large and heavy workpieces

The size and efficiency of the milling machine being supplied, which is also capable of turning components thanks to the integrated rotary table — tried and tested as part of the Dörries range of lathes from the Starrag Group — was of fundamental importance. The Droop+Rein G 110 TT HR100 C owes its high precision to features such as the hydrostatic guides in all linear axes, as well as the thermosymmetrical design of the milling unit with integrated C axis.

Milling heads can be changed automatically via a head change interface. The team responsible selected five different machining heads to use in this project: The high-performance fork milling head is outstanding, possessing not only the ability to use the tool at any angle but also the necessary prerequisites for heavy-duty machining on five axes simultaneously. Alternatively, the machine can be used with one straight and one angled 100-kW milling head with a torque of 7,500 Nm. A turret and a horizontal facing head are available for turning operations on the components.

The large, multifunctional machine supplied by Starrag from its Bielefeld plant gives the operator optimum access. The operator can reach any point on the workpiece thanks to the spacious cabin, which travels along the gantry and features the latest Siemens operator panel. The cabin can reach a height of 8 m and be moved towards the centre of the table.

The last but no means least decisive factor in favour of the Starrag Group was that, having already supplied machines to reference customers, the company could prove that the installed machine technology is very robust. This ensures that, with proper maintenance, the machine will be operational for the entire duration of the submarine project — the first of the Attack class submarines will be delivered in the early 2030’s and continue into the early 2050’s.