Brazilian petrochemical company Braskem has partnered with 3D printer manufacturer and service provider Titan Robotics to launch a new polypropylene (PP) resin.

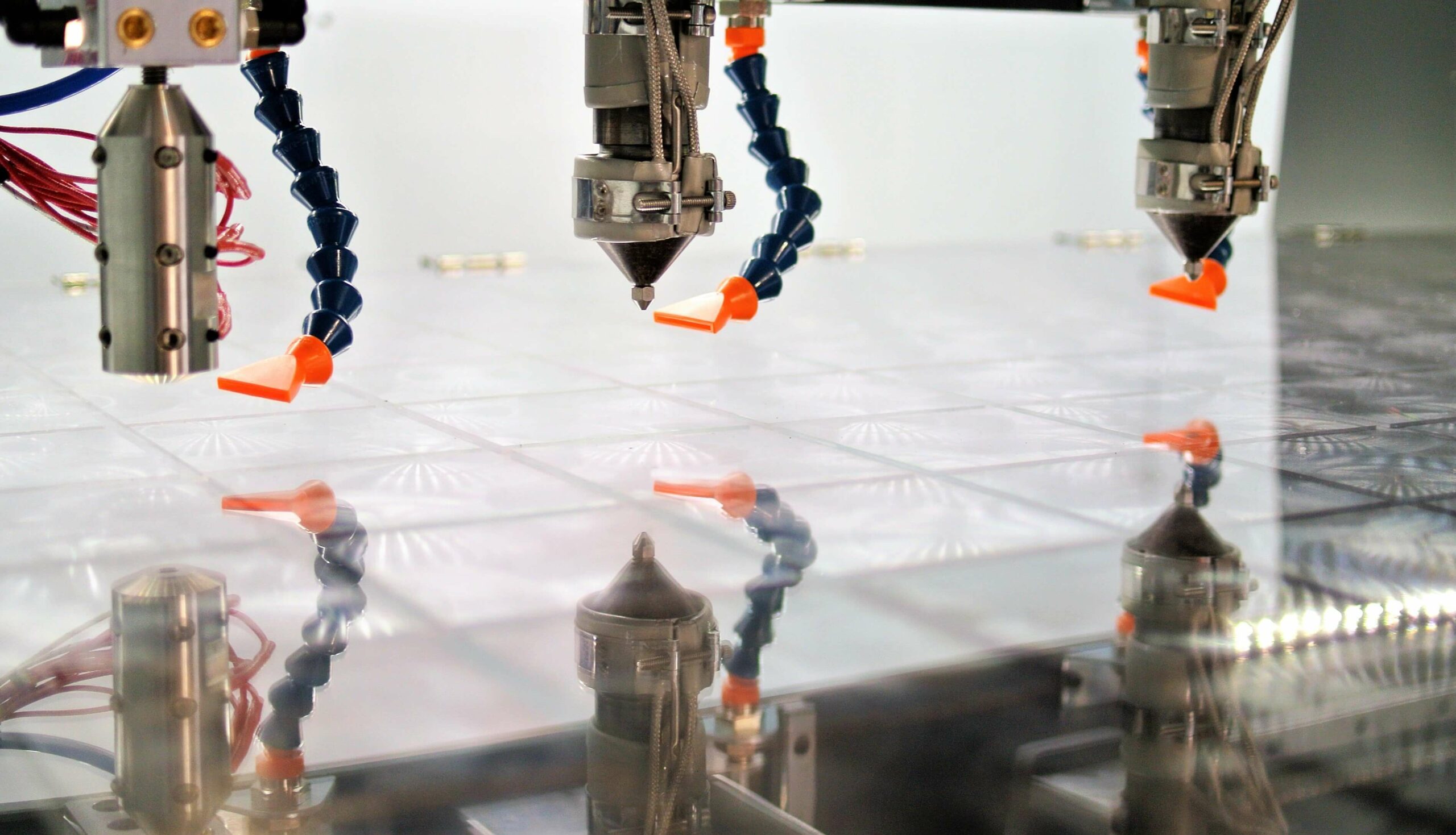

Developed as part of the companies’ ongoing collaboration, the pellet-based polymer is the first commercially-available PP to be specifically engineered for Titan’s Atlas line of dual extrusion 3D printers. What’s more, the material has also been optimized for producing large-format production parts, potentially enabling its use in a variety of applications such as the production of automotive parts, packaging, and live hinges.

“Through Braskem’s partnership with Titan Robotics, a leader in high-speed 3D printing market, we have combined competencies in machine development and polymer design to introduce a unique product to the market,” said Jason Vagnozzi, Braskem Additive’s Manufacturing Leader in North America. “We look forward to our continued collaborations with Titan.”

“IT IS OUR GOAL TO CONTINUE TO LISTEN TO THE NEEDS OF OUR CLIENTS AND EVOLVE OUR 3D PRODUCT PORTFOLIO TO BEST SUPPORT THE VALUE CHAIN.”

Braskem’s continually expanding materials portfolio

Founded in 2002, and based in Sao Paulo, Brazil, Braskem has a considerable history of developing plastics for new applications, especially within the aerospace industry. Working with Made in Space (MIS) and NASA for instance, the company developed a plastic recycling facility for the International Space Station. The ‘Braskem Recycler’ was designed to reduce waste aboard the station, and lessen its reliance on resupply missions from Earth.

Later, Braskem expanded its Innovation & Technology (I&T) Center in Pennsylvania to include a dedicated lab for additive manufacturing. The new 2,800-square-meter facility represented the petrochemical company’s first major step into producing 3D printing materials. A year later, Braskem announced a collaboration with Advanced Laser Materials (ALM), a subsidiary of the EOS company, which culminated in the launch of its first PP material.

More recently, in May 2020, the company established its own portfolio of 3D printing materials and revealed that it had partnered with Titan Robotics to develop a powder-based resin. As part of their collaboration, Titan has also taken on the role of authorized distributor of Braskem’s products, and it has now begun to commercialize their newly-released PP resin.

Overcoming Titan’s pellet problem

Despite the fact that Titan’s flagship Atlas-H line of machines are able to print at speeds of up to 30,000mm per minute, producing larger components with PP resins has reportedly proven troublesome. Moreover, as polymer pellets remain an attractive resin to work with, offering a high level of recyclability, impact strength, and chemical-resistance, Braskem and Titan have worked to resolve this compatibility issue since 2019.

Now, having collaborated on the R&D of their new photopolymer for over a year, the companies have brought the benefits of PP printing to the production of large-format components for the first time. “3D printing large parts using polypropylene resin has been a challenge for many years. In collaboration with Braskem, a global leader in the polypropylene market, we have now solved that challenge,” said Rahul Kasat, Chief Commercial Officer of Titan Robotics.

In addition, parts produced using the new pellets reportedly display a low amount of warping and strong inter-layer adhesion, overcoming the traditional challenges of 3D printing with PP. These characteristics potentially make the polymer well-suited to a wide range of industrial applications within the automotive, storage, and chemical and gas sectors.

According to Titan, the companies plan to continue collaborating to develop new grades and custom compounds of Braskem’s polypropylene resin, in order to meet the needs of their clients. “Our industrial customers will now be able to print functional parts with this first of its kind polypropylene grade,” concluded Kasat. “We are excited to continue to develop new polypropylene-based solutions for our customers in collaboration with Braskem.”