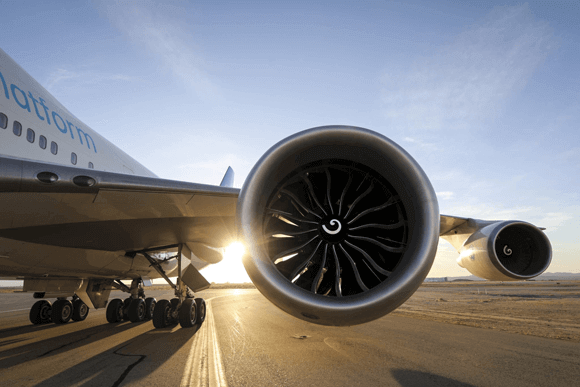

GE Aviation reports that its GE9X engine, which contains over 300 additively manufactured parts, has been certified by the U.S. Federal Aviation Administration (FAA) authorities.

Said to be a key milestone in the company’s journey to power the new twin-engine Boeing 777X family, the certification follows a test flight of GE Aviation’s GE9X engine on a Boeing 777X in January 2020.

The FAR (Federal Aviation Regulation) Part 33 certification involved nine test engines and culminates GE Aviation’s renewal of its commercial jet engine portfolio, including the GEnx for the Boeing 787 Dreamliner and the CFM LEAP engine.

The GE9X engine is designed to achieve 10% lower specific fuel consumption (SFC) compared to the GE90-115B and 5% better SFC than any other engine in its class. The engine will reportedly also operate with less smog-causing emissions than any other engine in its class. The GE9X test engines completed just under 5,000 hours and 8,000 cycles for certification.

Almost 300 AM parts are reported to be in each GE9X engine, including many that combine multiple parts into one component, as well as parts that cannot be made in any other way. AM parts are produced at GE’s Avio Aero facility in Cameri, Italy, and GE’s Additive Technology Centre in West Chester, Ohio, USA, and are reported to include fuel nozzle tips, low-pressure turbine blades, heat exchangers and inducers.

GE Aviation states that its focus remains on working with Boeing to complete the 777X flight test programme and entry into service. Eight GE9X test engines and two test spares have been produced and delivered to Seattle, Washington, USA, for Boeing’s four 777X test aeroplanes. Several GE9X production engines have been assembled, and GE Aviation is in the process of completing factory acceptance tests.

In addition, GE Aviation is currently conducting 3,000 cycles of additional ground testing on the GE9X engine to support Extended Operations (ETOPS) approval as well as maturation testing to help its engineers prepare to support the engine in service.

For service and support of its customers, GE Aviation has established GE9X engine training courses at its Customer Technical Education Center (CTEC) facility in Cincinnati, Ohio, USA. A GE9X engine currently at CTEC is being used to develop lean maintenance practices that will be implemented in customer training modules and GE training procedures.

“It takes the world’s best talent in jet propulsion to create a game-changing product like the GE9X engine,” stated John Slattery, president and CEO of GE Aviation. “There is no substitute that can achieve the combination of size, power and fuel efficiency of the GE9X.”

Slattery continued, “This engine will deliver unsurpassed value and reliability to our airline customers. I want to congratulate the entire GE9X team and thank Boeing, our partners and suppliers for the collaboration on this incredible achievement.”

Bill Fitzgerald, vice president and general manager of Commercial Engines Operation for GE Aviation, commented, “Just as the GE90 pioneered new technology for commercial aircraft engines more than twenty-five years ago on the Boeing 777, the GE9X sets the new standard for engine performance and efficiency thanks to the incorporation of GE’s most advanced technologies developed over the last decade.”

Karl Sheldon, GE9X programme General Manager, reported, “This milestone has been accomplished thanks to the tremendous efforts of the GE9X team and our partners.”

Sheldon added, “The GE9X engine has been through a rigorous and thorough certification and testing process. We are pleased with the performance of the engine, which has been validated through extensive ground and flight testing. We are excited to deliver a mature, state-of-the-art product to operators around the world.”