The Belaz 75710 is the biggest dumptruck in the world, one capable of moving 450 tonnes in one go.

When you are mining the world for its natural resources, it’s no surprise to know that every penny counts. As a report from analysts PwC, not only are costs are rising, but also commodity prices are increasingly volatile ‒ not to mention other challenges such as resource nationalism.

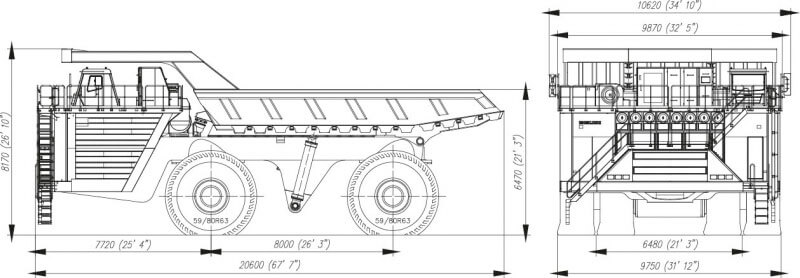

To tackle at least part of the cost challenge, the state-owned company Belaz in the former Soviet republic of Belarus has created what is probably the biggest dumptruck in the world ‒ the Belaz 75710. It’s as long as two double decker buses parked end-to-end, six times as powerful as today’s Formula 1 racing cars and weighs more than a fully loaded Airbus A380 passenger plane. If you stood next to it, you’d struggle to reach halfway up one of its eight tyres – unless you’re at least 6ft 7in (2m) tall.

The truck was unveiled in 2013, but the first ‒ and so far, only ‒ Belaz 75710 began shifting rocks at a coal mine in Siberia in mid-October 2014. With a hauling capacity of 450 tonnes, it can carry 87 tonnes more than the current record holder.

Enormous engines

To help it carry more than existing vehicles, its makers have incorporated a range of design features. It has eight wheels in pairs, compared to the more usual six. Each tubeless pneumatic tyre can support 102 tonnes, allowing them to carry the maximum capacity load on top of the 350 tonnes the empty vehicle weighs.

The monster truck has a diesel-electric transmission system. Two 16-cylinder diesel engines drive generators which produce electricity to power four electric motors – compare that to the four or six-cylinder engine that powers your average family car.

However more important for a vehicle that is constantly stopping, starting and pulling heavy loads up hills is how much torque, or turning power, it boasts. The Belaz 75710 has a pretty extraordinary peak torque of 13,738 lb/ft (18,626Nm) – about 24 times what a 2014 Formula 1 car’s engine can manage.

Fuel consumption is an estimated 1,300 litres per 100km, however the “haul truck”, as such a vehicle is known in the mining industry, can be run on just one of its engines when it is not loaded in order to save fuel.

Siemens engineers, who developed the drive system, unusually opted for all-wheel drive, to provide improved traction distributed over both axles. It also means that if one of the electric motors fails it can still be driven back to a repair centre under its own steam ‒ a handy feature when tractors capable of hauling a machine this large back to the depot are thin on the ground.

“I feel proud to be driving such a giant,” said Andrej Vashkevich, a Belaz test driver and one of only two people to have driven the giant truck in real-world mining conditions. Vashkevich is currently using this Belaz 75710 to move waste rock at an opencast coal mine in the Kuzbass region of Russia. The site is mined by the large coal producer SDS-Ugol, which is part of the Sibirsky Delovoj Soyuz holding company.

“It is easy to drive but you do need a little time to get used to its dimensions. The all-wheel drive makes it easier to drive in tough conditions such as on slippery roads and braking is more efficient.”

Tight turns

There is little point having a giant truck that can carry huge loads if it isn’t easy to manoeuvre. To allow drivers to get where they want to quickly, both axles steer. Its turning radius is 65ft (19.8 metres), not much more than the 56ft (17.2 metres) for its little brother, the Belaz’s 360 truck, which is the next-largest dumper truck the company currently makes. (That’s shorter than the distance between the wickets on a cricket pitch – though a groundsman might have something to say about a Belaz 75710 being on the pitch.)

The 26ft (8.2 metres)-high truck has a top speed of 40mph (64km/h), and can still travel at 25mph (40km/h) while climbing a 10% gradient. It can handle short stretches of 18% gradient.

Siemens engineers are able to monitor the truck’s performance, diagnose problems and provide the Belaz 75710 with new software without leaving their offices in Alpharetta, in the US state of Georgia, thanks to its remote connectivity.

“For engineers in the US to have to go suddenly to Russia if there is a problem is not feasible, so connectivity is an essential feature,” said Joy Mazumdar, business manager (mining haul trucks) at Siemens, who led the team which developed its drive system.

‘Great piece of engineering’

Two more Belaz 75710s are currently under construction. The price tag for anyone considering buying one; a little over $6m (£3.84m).

The current holder of the Guinness World Records title for the largest dumper truck in the world is the US-built Liebherr T282B, which has a capacity of 363 tonnes. So the Belarussian giant could prove to be a popular new addition for mining corporations. “It’s a great piece of engineering and if it can operate efficiently it’s impressive,” said Bryan Pullman, a UK-based senior mining engineer at international mining and engineering consultancy Golder Associates.

“Using two engines combined makes it a bit of a complex mechanical system, so I wonder about operating efficiency and fuel consumption. But even if it only knocks a few pence off per tonne, it could have a big impact on production costs in some of the world’s large coal, iron ore and copper mines.”