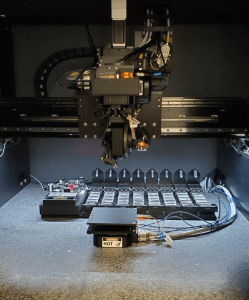

nScrypt’s new “3Dn-Axis” Factory in a Tool (FiT) achieves 3D manufacturing in 6 axes, and therefore enables digital manufacturing in true 3D.

With 6-axis capability for all of its tool heads, nScrypt’s new FiT can microdispense with its SmartPumpTM tool head, 3D print with its 3Dn material extrusion tool head, mill or polish with its nMill tool head, and integrate electronic components with its pick and place tool head in true 3D, not just in the XYZ planes.

For example, the nFD tool head can 3D print the structure or housing of an electronic device, the SmartPumpTM can microdispense conductive traces, the pick and place tool head can add electronic components, and the milling tool head can give the device a fine surface finish, all in 6 axes.

According to nScrypt’s CEO, Ken Church, “We are finding that printing only in XYZ just isn’t meeting customer needs. Rather than 3D printing parts, they want to do precision digital manufacturing of finished products in true 3D, such as integrating circuits and electronic components, like sensors, in helmets and other wearables, or in projectiles, drones, or medical devices.

Our 3Dn-Axis Factory in a Tool solves two problems: the ability to 3D manufacture complete products, like functioning electronic devices, and the ability to do so in true 3D, making complex shapes with integral electronics and fine surface finish. Our new FiT allows our customers to move beyond XYZ 3D printing to true 3D manufacturing.”

nScrypt’s system uses 6 axes of motion (3 linear and 3 rotational) to achieve continuous 5 axis printing. The six axes are the usual X, Y, and Z, plus RS, RT, and RR. RS is the axis connected to the Z stage, which spins the tool head. RT is the axis connected to RS, which tilts the tool head. RR is connected to the bed and spins the bed.