3D printing system manufacturer Onulis has launched an industry-first machine that’s capable of turning expired UV resin into a safely-disposable solid plastic.

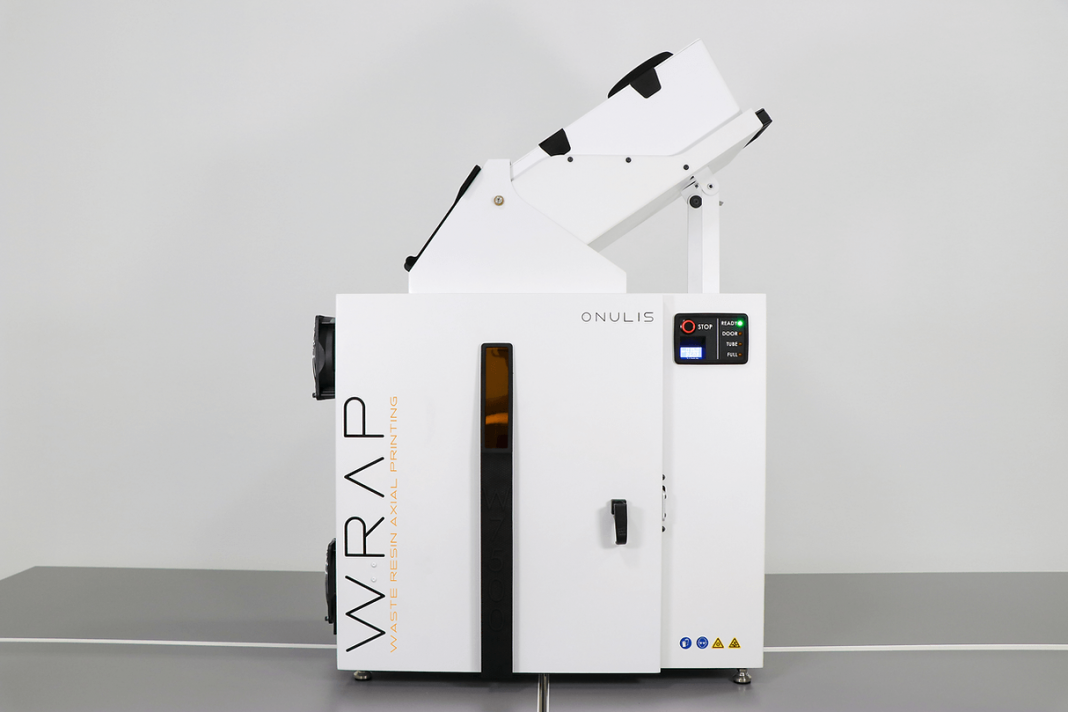

Built around Onulis’ patented Waste Resin Axial Printing (WRAP) technology, the W7500 allows adopters to recycle used or expired UV feedstock into materials that don’t require specialized end-of-life disposal. According to its creators, the fully-automatic machine’s ability to reuse resin allows it to “operate at virtually zero cost”, while yielding plastics with potential product prototyping applications.

Unraveling ‘WRAP’ technology

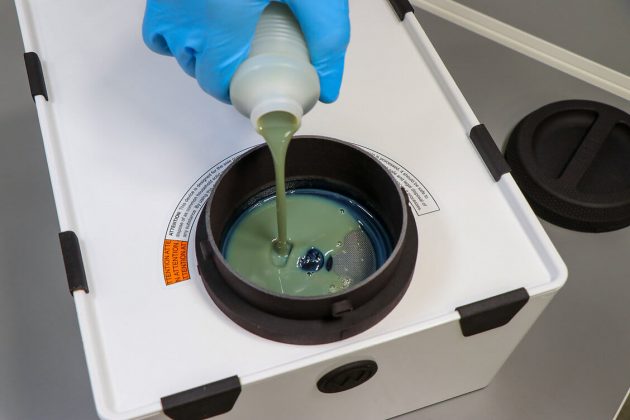

Founded with the stated aim of developing products that help resolve 3D printing’s biggest pain points, Onulis’ new launch targets one of resin printing’s most problematic issues: waste material disposal. At present, the firm says that disposing of used or expired UV resin requires manufacturers to either embrace “messy do-it-yourself methods” or costly services, who are forced to “simply bury sealed drums of hazardous material in landfills” to solve the problem.

If manufacturers do choose to go it alone, the time-consuming chore of resin disposal first involves manually exposing thin layers of used material to the sun, before stirring partially-cured polymers to continually reveal uncured underlayers. This painstaking process then needs to be repeated until the material is completely cured, in a workflow that can involve exposure to caustic materials.

What’s more, if a hazardous waste company is contracted, the manufacturer will first be forced to register with the Environmental Protection Agency as a generator of such waste. In cases like this, users are then required to store large drums of waste on-site until sufficient quantities are collected for pickup.

The W7500 alleviates these pain points, while allowing for faster, safer and more conscientious recycling, and the plastic generated by the printer is effectively zero-cost stock, which is ideal for use within CNC machining or product design.

Onulis’ W7500 resin recycler

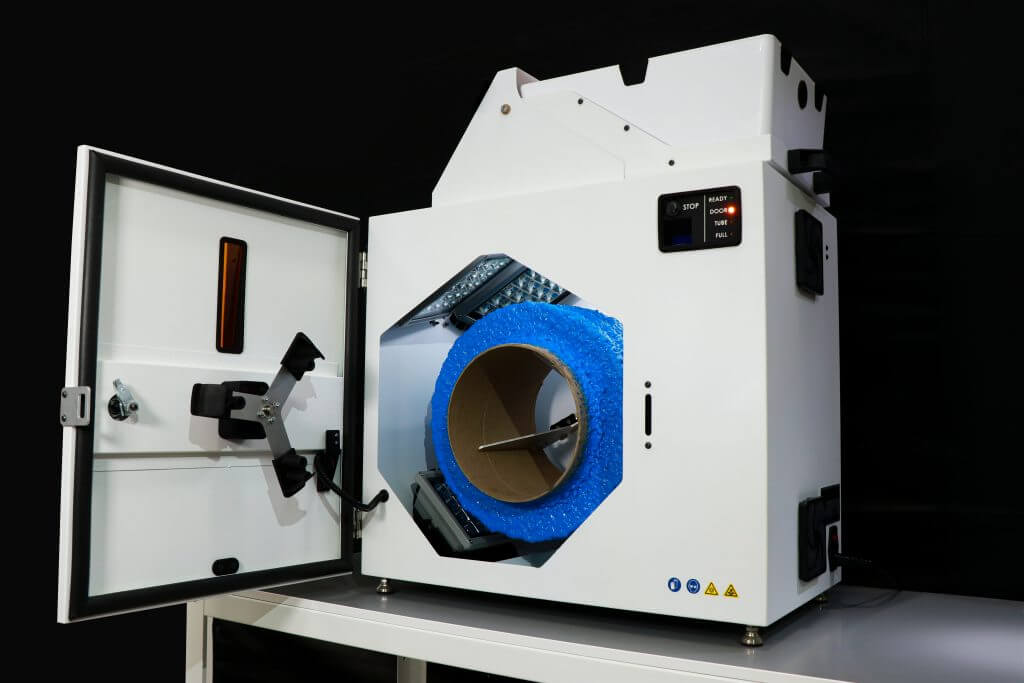

Now being marketed to manufacturers, Onulis’ first WRAP technology-powered machine, the W7500, features a space-efficient formfactor, allowing it to be compact while retaining a 7.5 liter-capacity, and its broad compatibility means that it’s capable of processing waste and expired resins from SLA, DLP, PolyJet and MultiJet 3D printers as well.

Thanks to its automatic timing functionality and axial printing architecture, the W7500 is able to run unattended, and it also features built-in carbon filtration. As a result, the system works to prevent adopters from being exposed to the toxic gasses often created when manually curing UV resins. The unit packs impressive efficiency too, enabling users to process thirty days’ worth of waste resin in just six hours.

Industry-tested innovation

Initial adopters of the W7500 include users from multiple different industries, ranging from universities to medical device manufacturers and 3D printing service providers, with early customers keen to highlight its material efficiency benefits.

“Our new W7500 has provided us with huge time and cost savings,” says Matthew DeGroat, Service Bureau Manager at Californian part provider and Onulis adopter Purple Porcupine. “We’re happily surprised that beyond just saving money, we’ve been able to minimize our team’s contact with hazardous waste and re-focus our labor on higher-value tasks.”