SLM Solutions Group and Divergent Technologies have signed a letter of intent to purchase next generation additive manufacturing machines and deepen their strategic partnership.

Since 2017, SLM Solutions and Divergent Technologies have worked under a joint development partnership to build a next generation multi-laser machine that achieves the cost-productivity necessary for volume manufacturing of automotive components, including safety structures, and aerospace parts.

Based on progress in the JDP and strong market demand the partners are now expanding their strategic partnership to speed up development and commercialisation of the next generation machines.

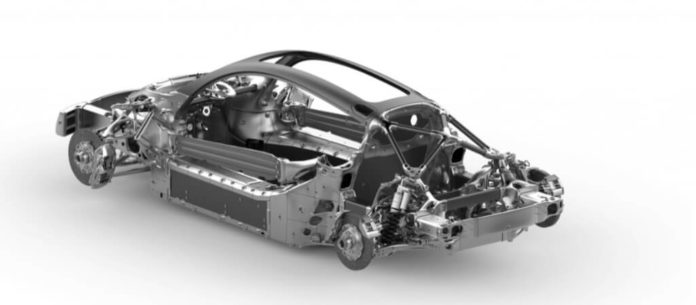

At Formnext 2019, the strategic partners have presented a front quarter-section of Divergent’s fully functional and crashworthy hypercar that features a printed chassis structure.

Additionally, they have showcased generatively engineered and validated lightweight suspension and chassis components, including a set of control arms manufactured on the first pre-production instance of the jointly developed machine.

The suspension and chassis structures being displayed were produced on SLM Solutions’ complete selective laser melting machine suite – including SLM800, SLM500 and SLM280 systems – and successfully endured over 450,000km of simulated road conditions.

Source: SLM Solutions

To accelerate the development and time to market of the next generation machines, Divergent will purchase five pre-production machines that will be used for factory integration and system bulletproofing at its showcase facility in Los Angeles, California.

According to Divergent’s CEO, Kevin Czinger, it plans to use the next generation machines to meet production demand for a number of major global carmaker programs.

Divergent’s initial factory deployment will require at least 20 next generation production machines when commercially available. Already in 2020, Divergent plans to begin series production of safety-critical structures for OEM customers in the US and Europe, followed by a customer rollout of advanced manufacturing facilities.

Meddah Hadjar, CEO of SLM Solutions said: “The next generation machine resulting from this partnership achieves cost productivity enabling the broad use of metal additive manufacturing for true series production.”

“Alignment between the two companies across machines, software, and materials will drive a step change from stand-alone AM machines to fully integrated smart factories,” added Kevin Czinger, founder and CEO of Divergent.