Everything you need to know about up and coming Hannover Messe 2019

The digital networking of man and machine in the age of artificial intelligence will be the focus of Hannover Messe 2019. Highlights are presented in the six line-up feature of the trade fair.

The guiding theme “Integrated Industry – Industrial Intelligence” of Hannover Messe 2019 from 1-5 April 2019 will underline the increasing importance of artificial intelligence and machine learning in industry and the energy sector. This includes topics such as efficient energy utilisation or autonomous production processes and also challenges with regard to interfaces, protocols and safety. International pioneers from the fields of AI and industry will come together in Hanover to discuss and develop solutions for tomorrow.

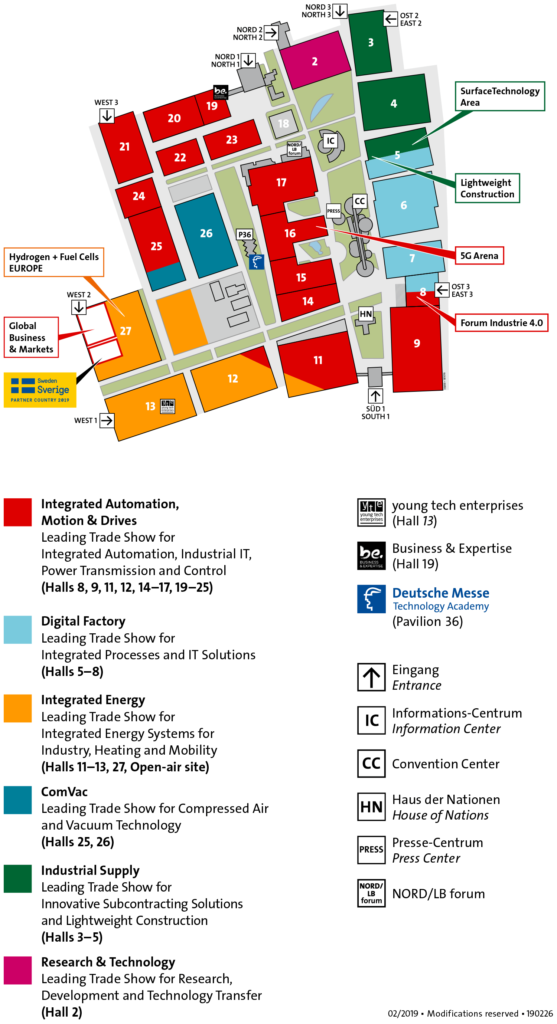

Apart from the six exhibition line-ups Industrial Supply, Digital Factory, IAMD-Integrated Automation, Motion & Drives, Comvac, Research & Technology and Energy, there are special areas for start-ups and career topics. More than 90 conferences and forums complement the programme. Partner country of the exhibition in 2019 is Sweden.

Industrial Supply 2019: Comprehensive range for lightweight construction

An important topic at Industrial Supply 2019 will be the question of why lightweight construction is a key technology for the future for industry and beyond. From materials, the possibilities of which many sectors are yet to discover to top conference on politics, research and industry, the focus will be on the concrete use of lightweight construction solutions and on strategies to provide this cross-sectional technology with even greater influence.

The central desire of lightweight construction is to improve the product or component, for example in load-bearing capacity, efficiency or design. In addition, lightweight construction makes efficient use of resources and materials and reduces both energy consumption and the associated emissions.

This increases competitiveness and, at the same time, makes a contribution to climate protection. Companies and associations will be presenting intelligent lightweight construction solutions throughout Hannover Messe, even though the focus on lightweight construction in the Industrial Supply sector will be in Hall 5.

The following formats and joint presentations deal with the topic of lightweight construction:

- Lightweighting Summit:The Federal Ministry of Economics has organised the first lightweight construction conference at Hannover Messe 2019. The top-level meeting with politicians, industry and research on 2 April will focus on the significance, the competitive situation and a strategy for promoting the key technology of lightweight construction. Federal Minister of Economics Peter Altmaier will open the conference and deliver the opening speech.

- Integrated Lightweight Plaza and Forum:The Integrated Lightweight Plaza in Hall 5 will serve as the focal point for lightweight construction and a marketplace for lightweight construction solutions across materials, processes and industries. Companies, networks, associations and research institutes use the Plaza to show that an optimal lightweight solution requires interdisciplinary co-operation in terms of materials, design and manufacturing technologies.

- Joint stand Lightweight Construction BW:At the joint booth “Lightweight Construction from Baden-Württemberg”, companies from Baden-Württemberg will present their know-how and lightweight construction solutions, including lightweight core materials for sandwich components, precise gears or transmission parts made of plastic or a combination of open die forging and 3D metal printing. The highlight of the joint booth is a very special exhibit: the ILO1. The lightweight concept vehicle was developed in just four months.

- Joint booth of the Lightweight Cluster: In order to turn business ideas into marketable products or services, co-operation with other companies, service providers and universities plays a decisive role, especially for small and medium-sized enterprises. This is why the lightweight construction cluster of the Landshut University of Applied Sciences and its partners will be participating for the ninth consecutive time at the Hannover Messe with a joint booth.

- Lightweight Construction Guide:The Lightweight Construction Guide draws visitors’ attention to the many companies which, across the entire Hannover Messe, offer relevant contributions in the field of lightweight construction.

- Guided Tour: A new offer is the daily Guided Tour called “Lightweight construction technologies in industrial applications”.

Surface Technology Area

From pre-treatment and coating to corrosion protection and functionalisation, surface technology is an indispensable part of every industrial production process. In Hall 5, at the Surface Technology Area, developers and designers as well as buyers will meet discussion partners on trends and opportunities in the field of surface technology in the direct vicinity of the topics of lightweight construction and additive manufacturing.

Additive manufacturing, for example, is playing an increasingly important role in surface technology. One reason is that the manufacturing processes result in rough and uneven surfaces.

In addition, users often expect an additional surface function, such as wear resistance, electrical or thermal conductivity. The first galvanic coatings of additive manufactured parts already exist. There will also be further synergies with the other exhibition areas in Hall 5. These include lightweight construction solutions, smart materials and bonding and joining technology.

The companies exhibit alongside the following topics:

- Parts cleaning and pretreatment

- Galvanic technology

- Painting technology

- Blasting technology

- Measuring, testing and analysis equipment

- Services

A joint booth of the VDMA and a presentation on industrial plasma surface technology has also been planned. Surface engineers will also have their say at the central Industrial Supply Forum in Hall 4: On Thursday morning, experts from industry and research will outline the forum programme and inform us all about new and proven solutions around surface technology.

Digital Factory: Optimising production with artificial intelligence

Based on the theme “Industrial Intelligence”, the industry will show at Hannover Messe 2019 how it uses artificial intelligence. The focus is on the use of artificial intelligence, Machine Learning and VR/AR. “The networking of machines in production and the development of smart components generate large amounts of data, which in turn form the basis for the use of innovative technologies such as Machine Learning, Digital Twins or VR/AR,” says Arno Reich, Global Director Digital Factory of the Hannover Messe team.

AI technologies, in particular machine learning and deep learning technologies, are currently finding their way into the factories of the manufacturing industry – challenges in industrial production that could previously not be solved or could only at great expense can now be tackled.

One example is the recognition of patterns and correlations based on unstructured data such as images, videos and sounds in combination with structured data from machines. The advantage: Such a link reduces the effort to identify errors or problems. Learning systems form the basis for continuous improvement in production tasks.

Applications for Industry 4.0 as well as solutions from the Cloud and Industrial Security, AI and Machine Learning, Digital Twin, VR/AR and Big Data Management sectors will be the main focus of the Hannover Messe presentation in Halls 5, 6, 7 and 8 with the theme “Digital Factory”. The topics in Halls 5 and 6 also include Engineering Software (CAx, PLM), Cloud Solutions, Virtual Reality and Additive Manufacturing. Hall 8 will focus on the transition to Automation and will house the Industry 4.0 Forum and initiatives and political platforms surrounding Industry 4.0 and the Smart Factory/Intelligent Manufacturing area.

A supporting programme will include various opportunities to deepen one’s own knowledge in specific areas of the digital factory and network with industry experts, which includes:

- the CAE Forum that deals with numerical simulation, 3D visualisation and additive manufacturing, as well as the one-day symposium Additive Manufacturing, where everything revolves around the use of new 3D printing processes in mechanical engineering, new hardware and materials in generative manufacturing.

IAMD 2019: Every solution for the smart factory

Whether smart sensors, intelligent drive solutions, modular production, automation in logistics or integrated solutions for intelligent manufacturing – IAMD 2019 will show the close interaction of automation, drive and fluid technology as well as software and IT, and present all modules and solutions for the factory of the future: Production and process automation, industrial IT, robotics, smart drive technology, intelligent hydraulics and pneumatics.

To equip one’s production with latest robotics technology, the chance here is to meet all the market leaders in Hanover, including Fanuc, Yaskawa, Kawasaki, Universal Robots, Hiwin and Mitsubishi. This area, growing year by year, reflects the current state of co-operation between humanbeing and robot. Keyword Cobots – the robot has long since become man’s colleague, not his competitor. Particularly innovative robotic solutions are again honoured at the Robotics Award.

Sensor technology is also at the heart of the integrated, networked and intelligent industry. Whether in energy technology, mechanical engineering or e-mobility – nothing in Industry 4.0 works without sensors. Sensors have meanwhile become the connecting theme at the Hannover Messe.

In addition to the company stands, trade visitors will once again find a supporting program with special presentations and forums. This includes

- Hannover Messe Pump Plaza

- the Wireless area

- M2M & IoT

- the Application Parkas a center for robot manufacturers, system houses and industrial image processing, as well as

- a new SME Pavilion, where small and medium-sized companies present their 4.0 solutions

- Forum Motion & Drives

- Automation Forum

- Forum Industry 4.0

Automation and IT – Partner in Industry 4.0

Just a few years ago there were two clearly separate areas: Automation on the one hand, IT on the other. However, these boundaries have been blurred by the digital transformation. The large automation companies and large machine builders have penetrated the world of digitisation and have become pioneers. In return, software companies have also discovered their interest in industry.

Industry 4.0 only works through close co-operation between IT and automation. It is obvious that this will not go smoothly. “The central challenge is in mutual understanding,” says Rainer Glatz, Managing Director of VDMA Electrical Automation as well as Software and Digitalization. “Different language worlds, disciplines and organizational units collide, which often leads to misunderstandings, conflicting interests and unnecessary competition.”

Many examples already show what successful co-operations can look like. For instance Adamos, the IIoT platform for mechanical and plant engineering developed in cooperation with Software AG. This solution aggregates machine data from different manufacturers in order to jointly develop Smart Services for customers. In their strategic partnership, ABB and IBM are focusing on artificial intelligence and machine learning.

The co-operation between Bosch and Huawei is still a very recent one. In October, the two partners announced that Bosch IoT services will be available in the strategically important Chinese market on Huawei’s cloud platform. Bosch and Huawei had also previously joined forces in the Industrial Internet Consortium to promote uniform industry standards, for example.

A merger of classic automation specialists and ICT representatives will also be provided by the ZVEI “5G Alliance for Connected Industries and Automation” (5G-ACIA). Their goal is to make the upcoming 5G mobile radio standard industrial-compatible and to establish it in industrial production in order to be able to implement Industry 4.0 even faster in the future.

Comvac continues to grow and reflects current industry trends

For Comvac, the Hannover Messe is recording a great demand on the exhibitor side: Hall 26 is already fully booked, with companies from China, Germany and Turkey in particular contributing to the strong growth. This is why Comvac exhibitors are moving to the southern part of the neighboring Hall 25 and to the open-air grounds.

Visitors can look forward to many new developments. For example, high-pressure air makes complex processes in the chemical and petrochemical industries simpler, and storage power plants use compressed air to secure power generated by the sun and wind.” Exhibitors will profit in particular by the synergies created with related drive and fluid technology topics.

Industry 4.0 will also be at the center of attention at Comvac, for example in the area of predictive maintenance or for tailor-made overall solutions such as leasing or billing per unit. Energy efficiency and resource efficiency remain important issues.

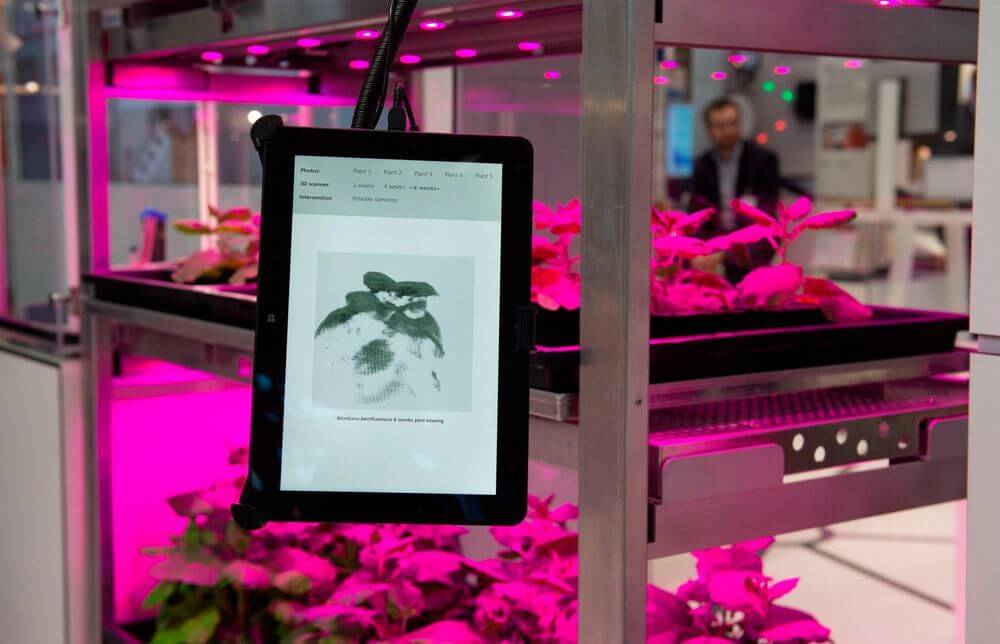

Research & Technology: Pioneering work of industry in the limelight

Multimodal sensor technology for industrial robots, powder-based additive manufacturing in zero gravity, energy management for distribution networks or a cold chamber die-casting machine. Whether in production, in the energy sector or in logistics, everything starts with research and development.

The Research & Technology area in Hall 2 at the Hannover Messe is a hub for research, development and technology transfer. Research institutions as well as established companies and start-ups will exhibit and present their pioneering work in areas such as artificial intelligence, human-machine collaboration, intelligent energy solutions, e-mobility and bionics.

Among the exhibitors that already registered are the Federal Ministry of Economics and Energy, the Fraunhofer Gesellschaft, the Karlsruhe Institute of Technology (KIT), the Christian-Albrechts-Universität Kiel, Hamburg Invest and the Association of German Engineers (VDI).

The supporting programme includes:

- the evening event Night of Innovations

- the Forum Tech Transfer, which is primarily concerned with innovation management and technology transfer: Participants will have the chance to meet future co-operation partners. The topics range from battery technologies, bionics and materials, lightweight construction, additive manufacturing and energy efficiency to start-ups, SMEs and Career 4.0.

- the Science|Square Forum, where seven German states present their innovations and the latest results, products and services.

- the Young Engineers Daythat is jointly organised by Deutsche Messe and the Association of German Engineers (VDI) on Thursday at the trade fair. The career day for young engineers and students of technical sciences consists of individual guided tours, lectures and workshops. It provides an overview of career opportunities and offers direct contact with potential employers. The day ends with the Young Engineers Night.

Energy 2019: Improved energy efficiency through digitalisation

The constant expansion of fluctuating renewable energy production as part of climate protection requires greater flexibility in all areas. This creates new challenges for the entire energy system. Flexibility and digitalisation are the key to the transformation of the energy system. At the Hannover Messe, technologies and solutions will be shown at the Digital Energy special show.

“The technologies for greater energy efficiency are already available,” says Anke Hüneburg, Head of Energy at the German Electrical and Electronic Manufacturers’ Association (Zentralverband Elektrotechnik- und Elektronikindustrie e. V.) (ZVEI), “but they can no longer be detached from the control and flexibility of energy use, that is, the question: How much energy is needed, when and where? Hüneburg emphasises on the additional opportunities that arise from this, especially from digitalisation: “The data and information gained through the digitalisation of the energy sector will make it possible to use technological solutions more efficiently and to finally make the flexibility potential for a cost-effective overall system profitable.”

The electrical industry is also pursuing completely new approaches. This is also reflected by the ambitious DC Industry research project, which investigates the extent to which a power supply for industrial plants can be redesigned using a smart, open DC grid and how the industrial energy supply architecture can be digitised. How DC technology will function in detail will be demonstrated to all visitors in Hall 12 as part of Integrated Energy at the joint Digital Energy stand of the participating companies and research institutes.

Sweden, partner country of Hannover Messe 2019, will set a strong accent with many participating companies and is also picking up on the changes in the energy industry. For Sweden, flexibility and digitalisation are key to switching the energy system to 100% renewable energy. Intelligent grids are indispensable for the energy supply of the future.

The potential of digital solutions in both the industrial and building sector must also be fully exploited in order to increase energy efficiency. This applies just as much to the transport sector and the issue of storage. “On the contrary, an increasing electrification of society will be slowed down without digital solutions,” says Dr. Verena Adamheit, project manager at the German-Swedish Chamber of Commerce responsible for Sweden’s presence at Hannover Messe.

Adamheit stressed on the “strong tradition of Sweden in the IT sector, including Ericsson, which laid the foundations for early digitisation.” Additionally, Sweden started very early with the expansion of its broadband infrastructure and continues to drive development forward with an ambitious digitalisation strategy.

Generally speaking, Sweden has a very positive climate for innovation; Swedes invest heavily in research, haa an affinity for technology and are enthusiastic about technical innovations and digital solutions.

All this has paved the way for the Swedish “tech wonder” à la Skype, Spotify, Klarna and I-Zettle. And in several segments, they are way ahead: The roll-out of smart metering in the Scandinavian country has already been completed, which benefits the rapid further development of smart home applications, intelligent network monitoring and e-mobility. Adamheit assures that Sweden will definitely present interesting new digital business models at the Hannover Messe 2019.

Source: Hannover Messe